Easily-prepared thermal visbreaking adhesive tape and preparation method thereof

A technology of adhesive tape and glue, which is applied in the direction of film/sheet adhesive, adhesive, pressure-sensitive film/sheet, etc., can solve the problem of inability to prepare heat-releasing adhesive tape, and achieve the effect of avoiding selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

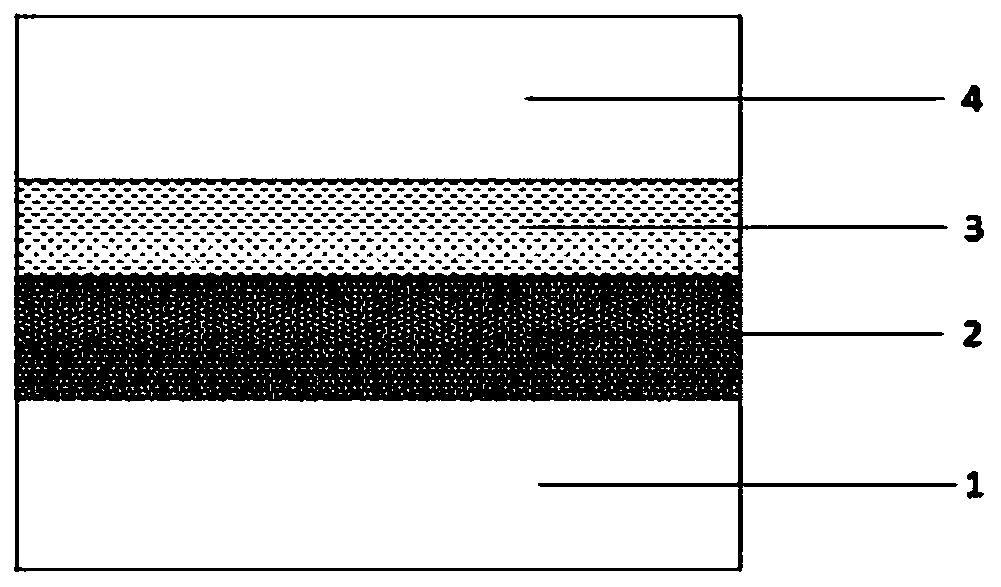

[0023] see figure 1 , the invention provides an easy-to-prepar thermal adhesive tape and a preparation method thereof, comprising a plastic substrate 1 coated with a thermal adhesive functional layer 2, the thermal adhesive functional layer 2 is debonded by heat The viscose is coated on the plastic base material 1 and cured to form, the thermal detackification functional layer 2 is coated with an adhesive layer 3, the adhesive layer 3 is coated with a release film 4, the plastic base material 1, the thermal detackification functional layer 2. Both the adhesive layer 3 and the release film 4 are bonded and fixed with an adhesive.

[0024] Specifically, the heat-viscosity-reducing adhesive is made by mixing resin, curing agent, solvent, self-expanding microsphere foaming agent, and toner.

[0025] Specifically, the adhesive is a solvent-type high-temperature-resistant polyacrylate pressure-sensitive adhesive.

[0026] Specifically, the plastic substrate 1 is one of 5-150 μm po...

Embodiment 2

[0036] see figure 1 , the invention provides an easy-to-prepar thermal adhesive tape and a preparation method thereof, comprising a plastic substrate 1 coated with a thermal adhesive functional layer 2, the thermal adhesive functional layer 2 is debonded by heat The viscose is coated on the plastic base material 1 and cured to form, the thermal detackification functional layer 2 is coated with an adhesive layer 3, the adhesive layer 3 is coated with a release film 4, the plastic base material 1, the thermal detackification functional layer 2. Both the adhesive layer 3 and the release film 4 are bonded and fixed with an adhesive.

[0037] Specifically, the heat-viscosity-reducing adhesive is made by mixing resin, curing agent, solvent, self-expanding microsphere foaming agent, and toner.

[0038] Specifically, the adhesive is a solvent-type high-temperature-resistant polyacrylate pressure-sensitive adhesive.

[0039] Specifically, the plastic substrate 1 is one of 5-150 μm po...

Embodiment 3

[0049] see figure 1, the invention provides an easy-to-prepar thermal adhesive tape and a preparation method thereof, comprising a plastic substrate 1 coated with a thermal adhesive functional layer 2, the thermal adhesive functional layer 2 is debonded by heat The viscose is coated on the plastic base material 1 and cured to form, the thermal detackification functional layer 2 is coated with an adhesive layer 3, the adhesive layer 3 is coated with a release film 4, the plastic base material 1, the thermal detackification functional layer 2. Both the adhesive layer 3 and the release film 4 are bonded and fixed with an adhesive.

[0050] Specifically, the heat-viscosity-reducing adhesive is made by mixing resin, curing agent, solvent, self-expanding microsphere foaming agent, and toner.

[0051] Specifically, the adhesive is a solvent-type high-temperature-resistant polyacrylate pressure-sensitive adhesive.

[0052] Specifically, the plastic substrate 1 is one of 5-150 μm pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com