Micro-fine particle nano-bubble flotation method and system

A nano-bubble and fine particle technology, applied in flotation, solid separation and other directions, can solve the problem of inability to achieve high-efficiency flotation separation of fine particles, and achieve more full utilization of great significance, improve quality, and reduce the loss of flotation recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

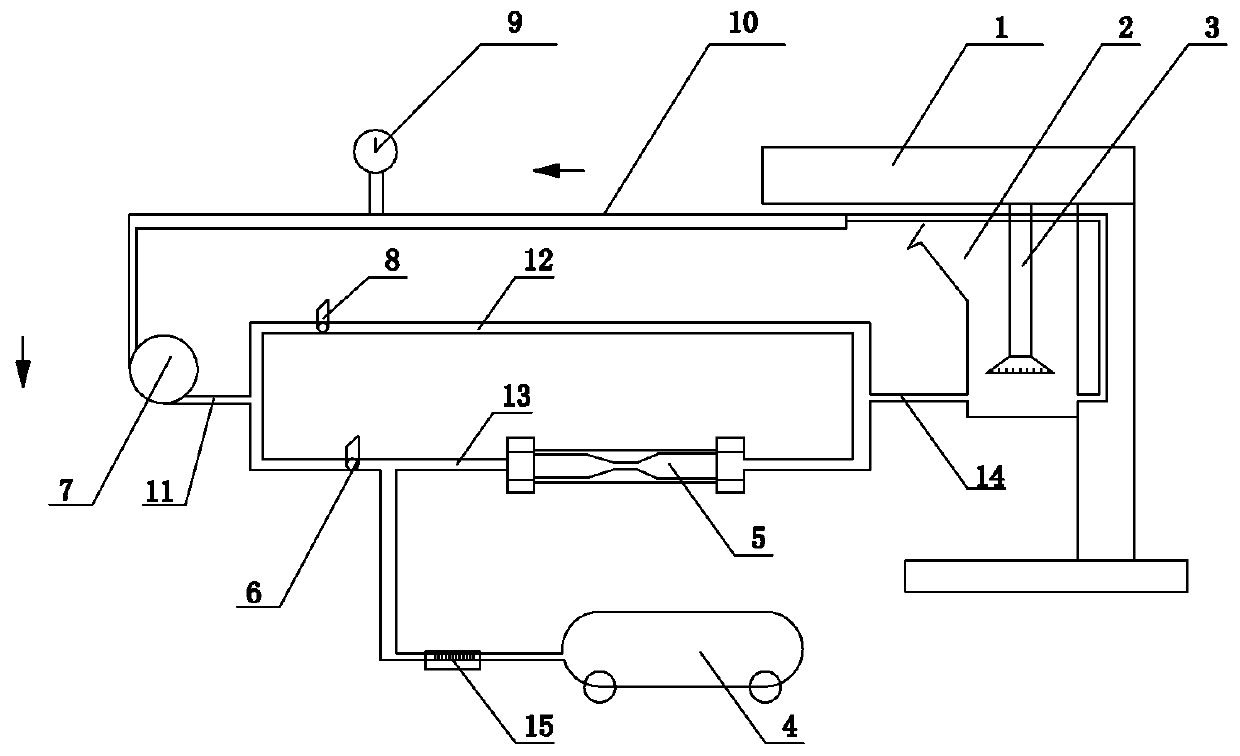

[0029] Such as Figure 1-Figure 3 Shown, a kind of fine particle nano-bubble flotation system of the present invention comprises flotation machine 1, is arranged on the flotation tank 2 and the stirrer 3 in the flotation machine 1, is characterized in that, in described flotation tank 2 The lower part of the front and rear walls is connected with an ore pulp nano-bubble inflation system, which is also connected with an air compressor 4; the pulp nano-bubble inflation system includes a circulation pump 7, pipeline I10, pipeline II11, pipeline III12, pipeline IV13, and pipeline V14 , control valve I8, control valve II6 and nano-bubble generator 5; the feeding port of the circulation pump 7 communicates with the lower part of the rear wall of the flotation tank 2 through the pipeline I10, and the pipeline I10 is provided with a pressure gauge 9, and the circulation pump T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com