Floatation separation technology of refractory lead-zinc sulphide ores

A technology for flotation of sulfide ores and minerals, applied in flotation, solid separation and other directions, can solve the problems of difficult separation of lead minerals and zinc minerals, low recovery rate of zinc concentrate, poor product quality, etc., and achieve lead and zinc flotation separation. Easy, improve flotation efficiency, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

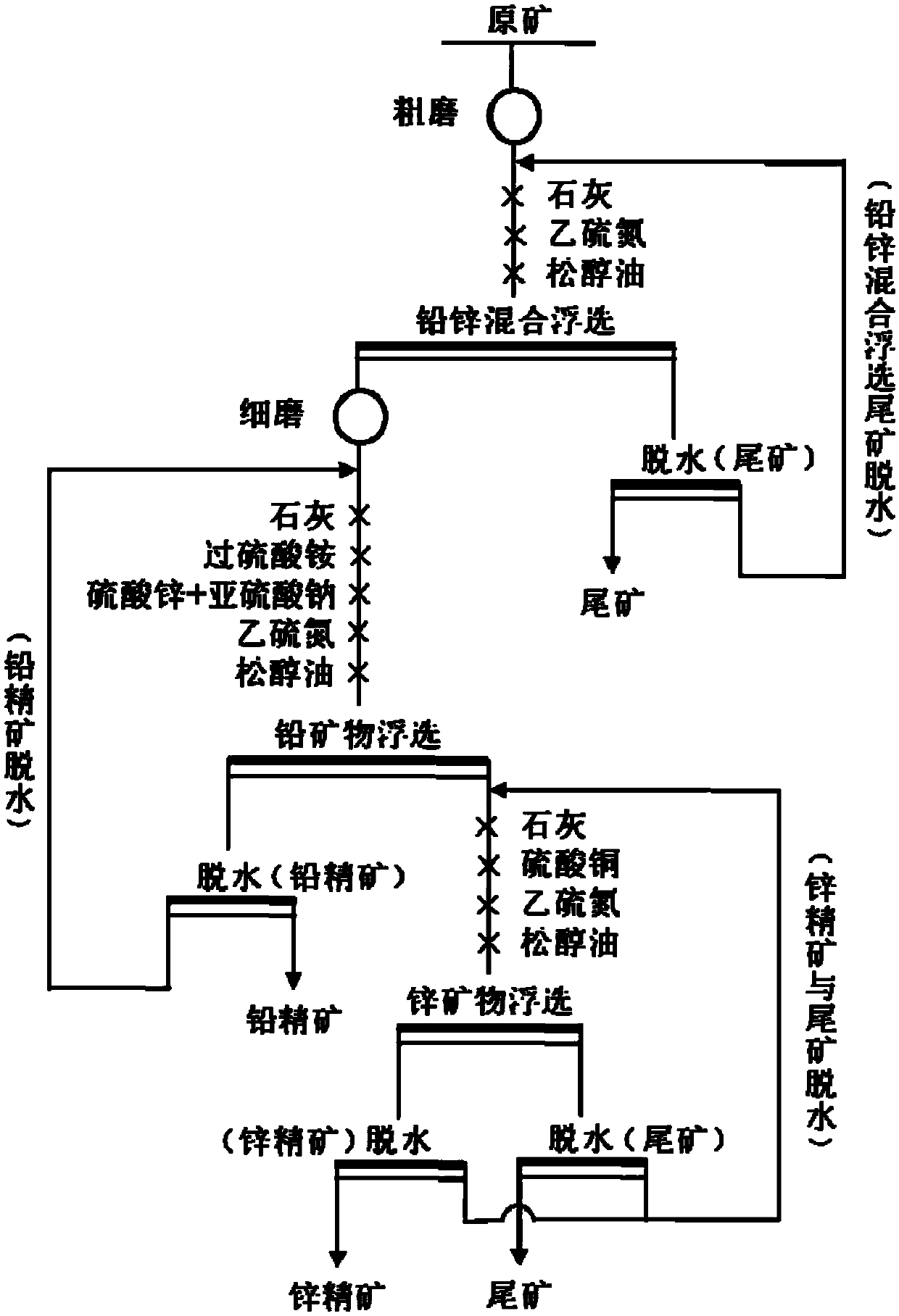

[0040] A kind of flotation separation process of refractory lead-zinc sulfide ore provided by the present embodiment comprises the following steps:

[0041] (1) Coarsely grind the lead-zinc ore with a lead grade of 1.19% and a zinc grade of 4.12% until the particle size is -0.074mm, accounting for 50%, and then add lime to adjust the pH value of the slurry to 10.1, and the amount of ethylsulfide nitrogen is 50g / t, The amount of pine alcohol oil is 20g / t, and the first roughing process of lead-zinc mixed flotation is carried out;

[0042] (2) The tailings of lead-zinc mixed flotation are dehydrated, and the removed waste water is reused in the lead-zinc mixed flotation process;

[0043] (3) Finely grind the concentrate of lead-zinc mixed flotation until the particle size is -0.074mm, accounting for 70%, then use lime to adjust the pH value of the pulp to 10.5, ammonium persulfate to adjust the pulp potential to 250mv, and the amount of zinc sulfate to 400g / t 1. The dosage of s...

Embodiment 2

[0049] A kind of flotation separation process of refractory lead-zinc sulfide ore provided by the present embodiment comprises the following steps:

[0050] (1) Roughly grind the lead-zinc ore with a lead grade of 1.07% and a zinc grade of 3.94% until the particle size is -0.074mm, accounting for 55%, and then add lime to adjust the pH value of the slurry to 10.2, and the amount of ethylsulfide nitrogen is 45g / t, The amount of pine alcohol oil is 15g / t, and the primary roughing process of lead-zinc mixed flotation is carried out;

[0051] (2) The tailings of lead-zinc mixed flotation are dehydrated, and the removed waste water is reused in the lead-zinc mixed flotation process;

[0052] (3) Finely grind the concentrate of lead-zinc mixed flotation until the particle size is -0.074mm, accounting for 80%, and then use lime to adjust the pH value of the pulp to 10.6, ammonium persulfate to adjust the pulp potential to 260mv, and the amount of zinc sulfate to 350g / t 1. The dosage...

Embodiment 3

[0058] A kind of flotation separation process of refractory lead-zinc sulfide ore provided by the present embodiment comprises the following steps:

[0059] (1) Coarsely grind the lead-zinc ore with a lead grade of 1.73% and a zinc grade of 6.28% until the particle size is -0.074mm, accounting for 45%, and then add lime to adjust the pH value of the slurry to 10, and the amount of ethylsulfide nitrogen is 65g / t, The dosage of pine alcohol oil is 25g / t, and the primary roughing process of lead-zinc mixed flotation is carried out;

[0060] (2) The tailings of lead-zinc mixed flotation are dehydrated, and the removed waste water is reused in the lead-zinc mixed flotation process;

[0061] (3) Finely grind the concentrate of lead-zinc mixed flotation until the particle size is -0.074mm, accounting for 75%, then use lime to adjust the pH value of the pulp to 10.4, ammonium persulfate to adjust the pulp potential to 260mv, and the amount of zinc sulfate to 450g / t 1. The dosage of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com