Hydrocarbon amide-bi-hydroxamic acid compound and application thereof in mineral flotation

A hydrocarbon amide group and bishydroxime technology, which is applied to hydrocarbon amide group-bishydroxamic acid compounds and their application in mineral flotation, can solve the problem of limiting collector flotation performance and application, and normal temperature flotation. Poor performance, low selectivity, etc., to improve hydrophobic foaming ability, improve froth flotation efficiency, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

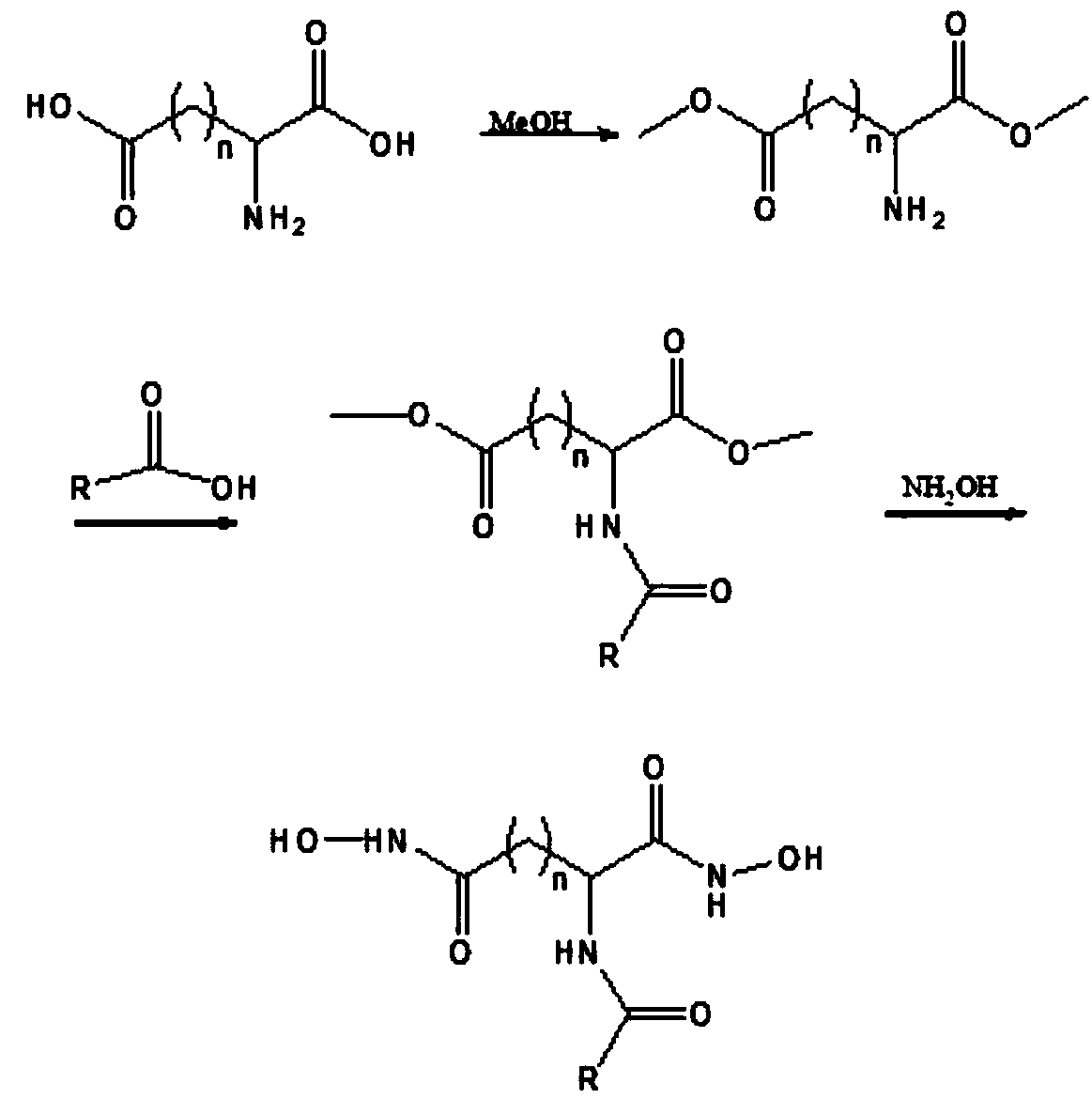

[0046] Example 1: Synthetic route of hydrocarbon amido-bihydroxamic acid compounds (taking octanyl amido-glutahydroxamic acid as an example)

[0047] Control the temperature of the reactor at about 60°C, add 14.71 parts of glutamic acid with a purity of 99% and 25.28 parts of methanol into the reactor, add 2.2 parts of concentrated sulfuric acid into the reactor under stirring, react for 4 hours, and steam the remaining methanol . Take 14.4 parts of octanoic acid and 16.2 parts of N,N'-carbonyldiimidazole in 25.28 parts of acetonitrile, react at room temperature for 30 minutes, add them into the reaction kettle, and distill off the methanol after 6 hours of reaction. Then add 6.95 parts of hydroxylamine hydrochloride and 8.00 parts of sodium hydroxide into the above-mentioned reactor, and add 50 parts of water as a solvent, further react for 3 hours, adjust the pH of the reaction solution with 0.1M hydrochloric acid to be 6, and obtain the required Caprylamide-glutarediohydro...

Embodiment 2

[0048] Embodiment 2: Application of hydrocarbon amido-dihydroxamic acid in tungsten ore flotation

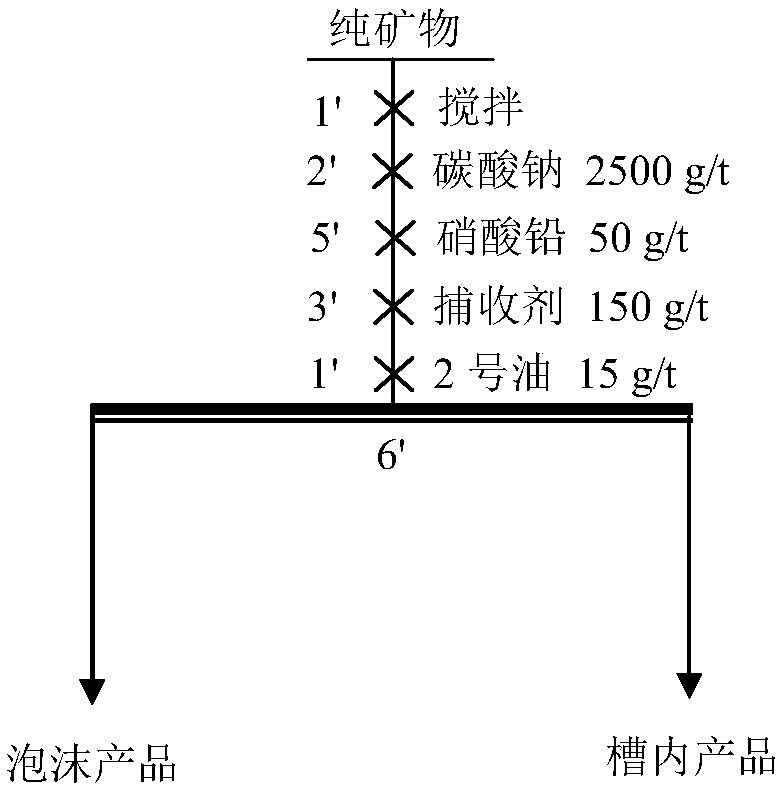

[0049] Put scheelite and wolframite pure minerals with grinding fineness -200 mesh accounting for 85% respectively in 40mL flotation tank, add 40mL water, stir for 1min to mix evenly, add 2500g / t of sodium carbonate to adjust pH Value, stirred for 2mins, then added the amount of collector 100g / t, foaming agent 2 # oil 15g / t under the conditions of flotation. The flotation contrast test results of two kinds of hydrocarbon amido-bihydroxamic acid and commonly used benzohydroxamic acid and octylhydroxamic acid in the present invention are shown in Table 1. Its flotation process flow chart is shown in figure 1 . It can be seen from Table 1 that the collection ability of hydrocarbon amido-bihydroxamic acid compounds to scheelite and wolframite is obviously stronger than that of two commonly used hydroxamic acids.

[0050] Table 1 The experimental results of four kinds of hydroxami...

Embodiment 3

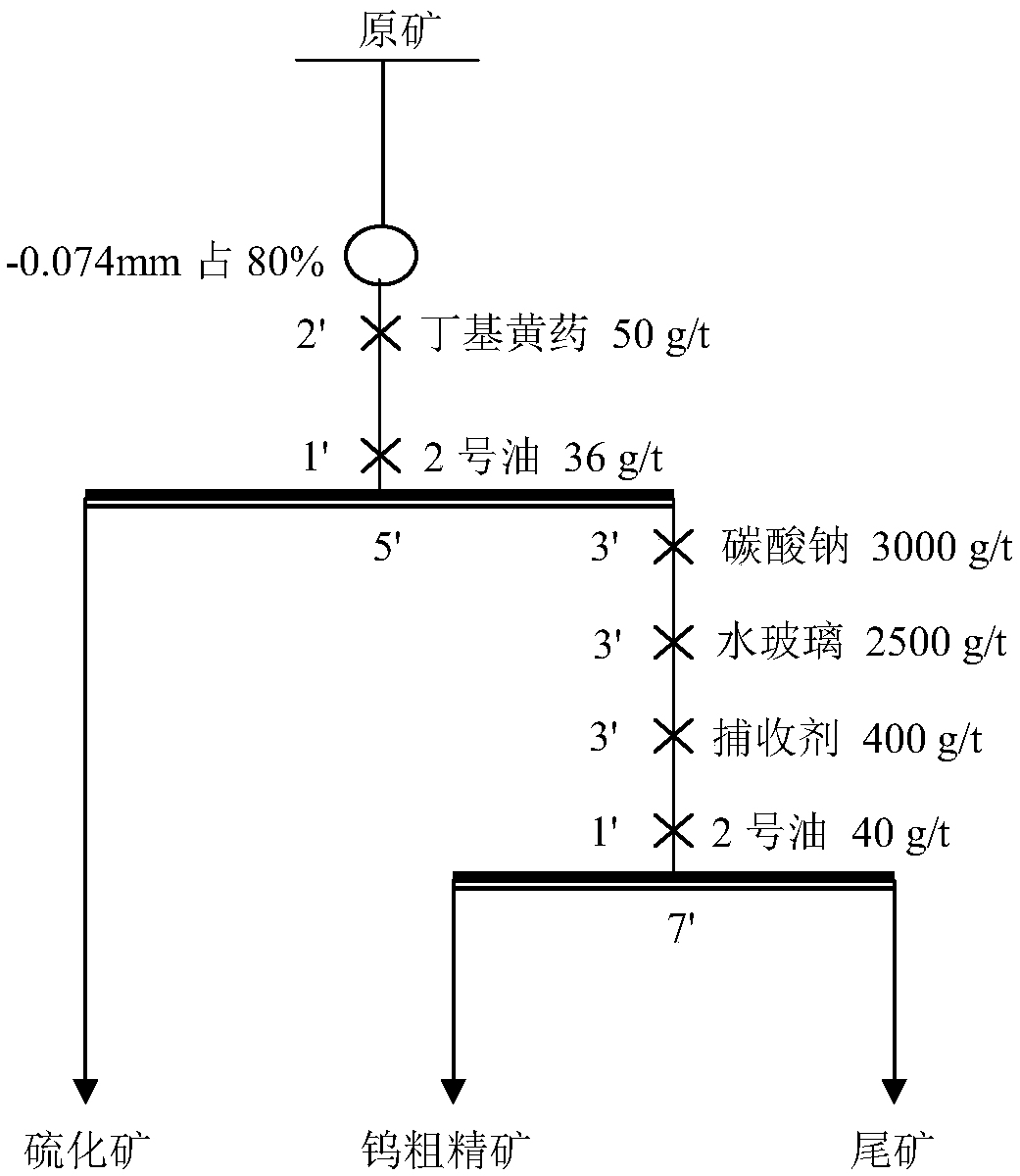

[0053] Example 3: Application of 2-decylamino-pentanehydroxamic acid in tungsten ore flotation

[0054] A sulfur beneficiation tailings containing WO in Yunnan 3 0.24%, grinding fineness -200 mesh accounts for 85%, use 3000g / t sodium carbonate to adjust pH value, 1500 g / t water glass as dispersant, collector dosage 400g / t, 2# oil 40g / t Under the condition of , after a roughing operation, tungsten crude concentrate is obtained, and the flotation results of hydrocarbon amido-dihydroxamic acid and octyl hydroxamic acid are shown in Table 2. It shows that, compared with octylhydroxamic acid, 2-decylamino-pentanedihydroxamic acid obtains a higher recovery rate of tungsten, and the recovery rate increases by 9.54%.

[0055] Table 2 Flotation conditions and results of tungsten ore

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com