Method for preparing titanium-enriched material from high-impurity-content ilmenite concentrate

A technology of titanium-rich materials and ilmenite, which is applied in the field of production of titanium-rich materials, can solve problems such as the inability to realize industrialization, and achieve the effects of less output of three wastes, easy handling, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

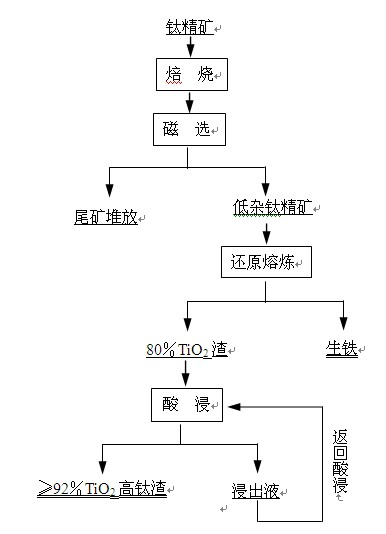

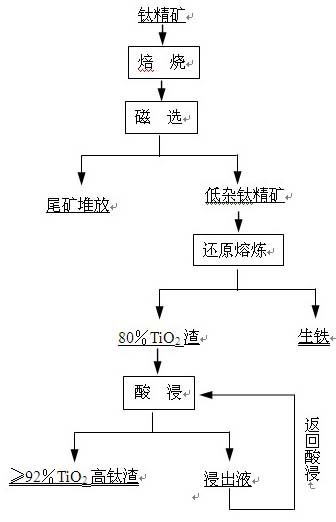

[0043] Aiming at the mineral characteristics of rock ore type ilmenite (such as Panxi vanadium titanomagnetite), the present invention provides a combined process flow consisting of many general processes, which is suitable for processing rock ore type ilmenite concentrate with high impurity content, And can produce high-quality titanium slag products, its technical route is: raw ore - magnetic separation - iron (vanadium) concentrate - tailings - flotation - ilmenite concentrate - roasting - magnetic separation - reduction smelting - titanium slag ( TiO 2 >80%)—purification—titanium-rich material (high-titanium slag), in which the production process of ilmenite concentrate is the same as the current production process, and the key point of the invention technology is the production of rich ilmenite concentrate (referred to as titanium concentrate) Titanium (TiO 2 >92%), taking Panxi ilmenite concentrate (referred to as titanium concentrate) as an example, the process is as f...

Embodiment 2

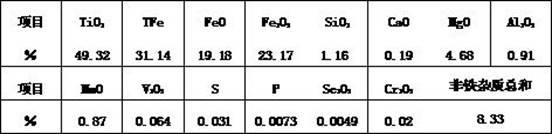

[0058] 1. Raw material of titanium concentrate

[0059] The raw material is titanium concentrate obtained by beneficiation and enrichment of Panzhihua vanadium-titanium magnetite ore, with a particle size of -200 mesh accounting for 29.8%. Its chemical composition is shown in Table 1.

[0060] Table 1 Chemical composition of titanium concentrate %

[0061]

[0062] 2. Roasting of titanium concentrate

[0063] Roasting is carried out in a rotary kiln. The optimal roasting conditions when the magnetic difference between ilmenite and gangue minerals is the largest are: roasting temperature 600-700°C, roasting time 1-3h.

[0064] ,magnetic separation

[0065] Grind the roasted titanium concentrate to -200 mesh, accounting for 50-85%, and perform titanium-rich and impurity removal magnetic separation under the condition of a magnetic field strength of 0.3T to produce titanium concentrate grade TiO 2 >49%, TiO 2 Yield > 95%, total impurities in titanium concentrate decrease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com