Optimization method for servo valve core working edge small burr online removal process system

An optimization method and a technology of a process system, applied in the online removal process system of small burrs on the working side of the servo valve spool, and the construction field of the servo valve processing system, can solve the problems of large burrs that are difficult to remove accurately and stably, and achieve The effect of reducing the scrap rate, difficult removal, and small burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. The following embodiments are based on the technical solutions of the present invention, providing detailed implementation and specific operating procedures, but the scope of protection of the present invention is not limited to the following implementations example.

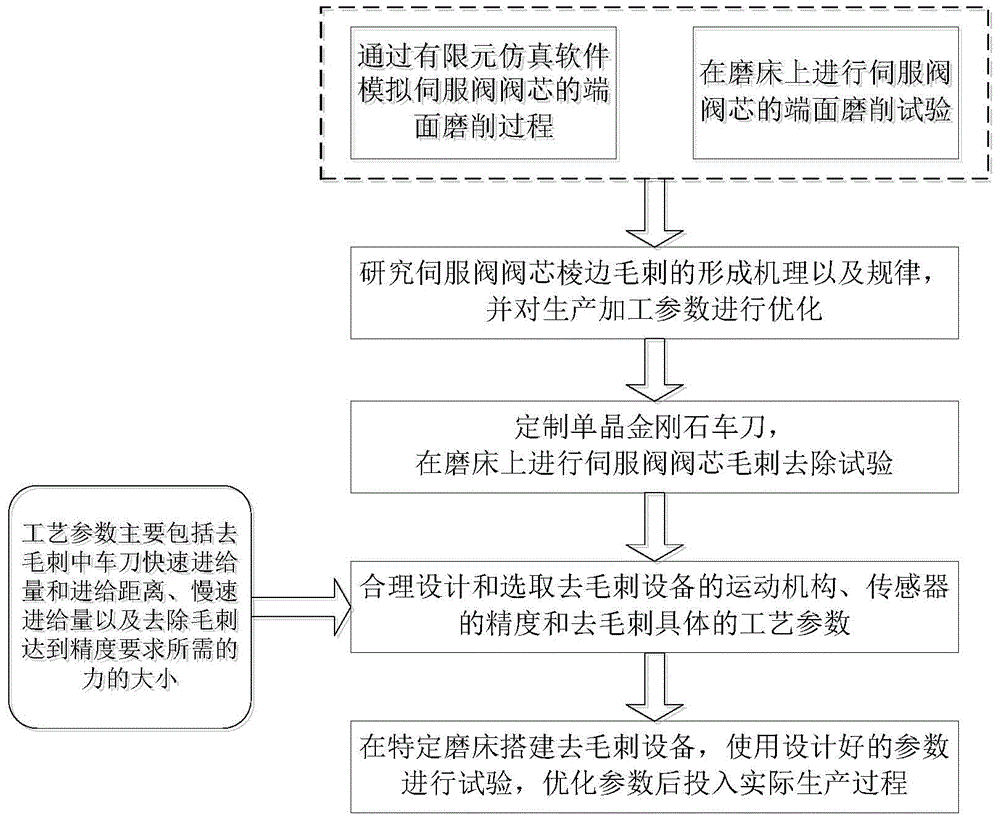

[0024] The optimization method of the on-line removal process system for micro burrs on the working side of the servo valve spool described in the present invention is realized through the following steps, please refer to figure 1 ; The size of the tiny burr is micron level, and the dimensional accuracy requirement of the valve core is also micron level:

[0025] (1) Valve core end face grinding simulation——According to the material and size of the valve core, use finite element software to simulate the end face grinding process of the valve core, simulate the generation process of burrs, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com