Secondary battery top cover and secondary battery thereof

A secondary battery, top cover technology, applied in battery cover/end cover, battery pack components, battery box/jacket, etc., can solve problems such as difficulty, high manufacturing cost, and increased stamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The secondary battery top cover and the secondary battery thereof of the present invention will be described below with reference to the accompanying drawings.

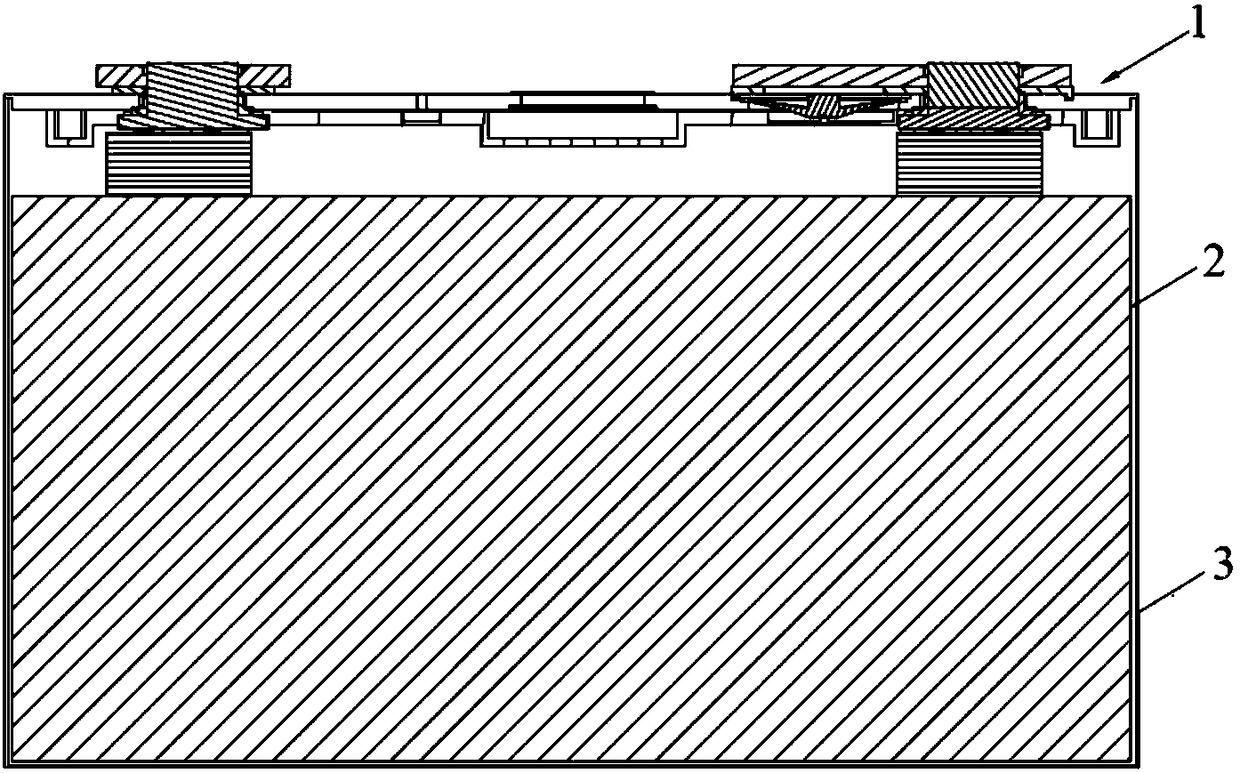

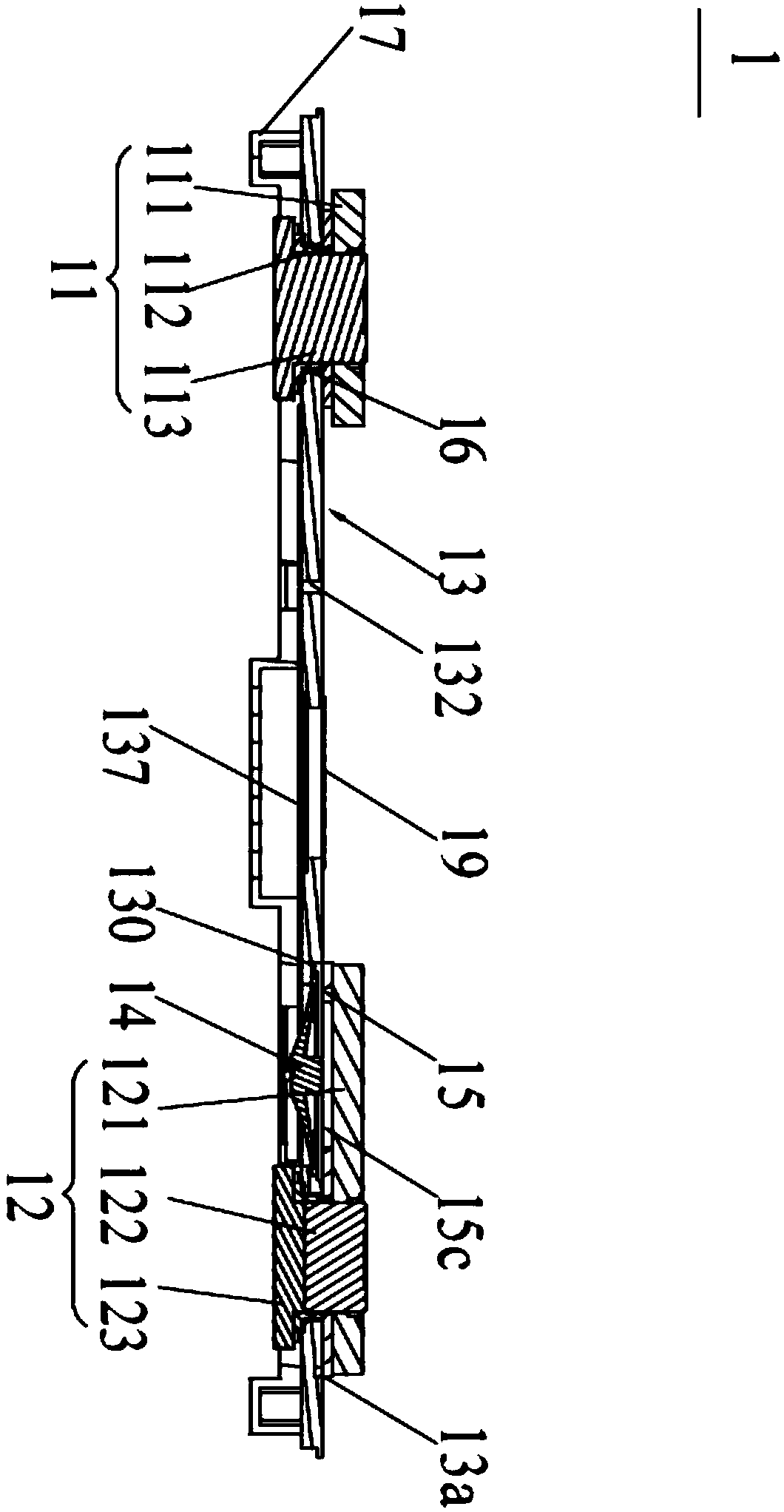

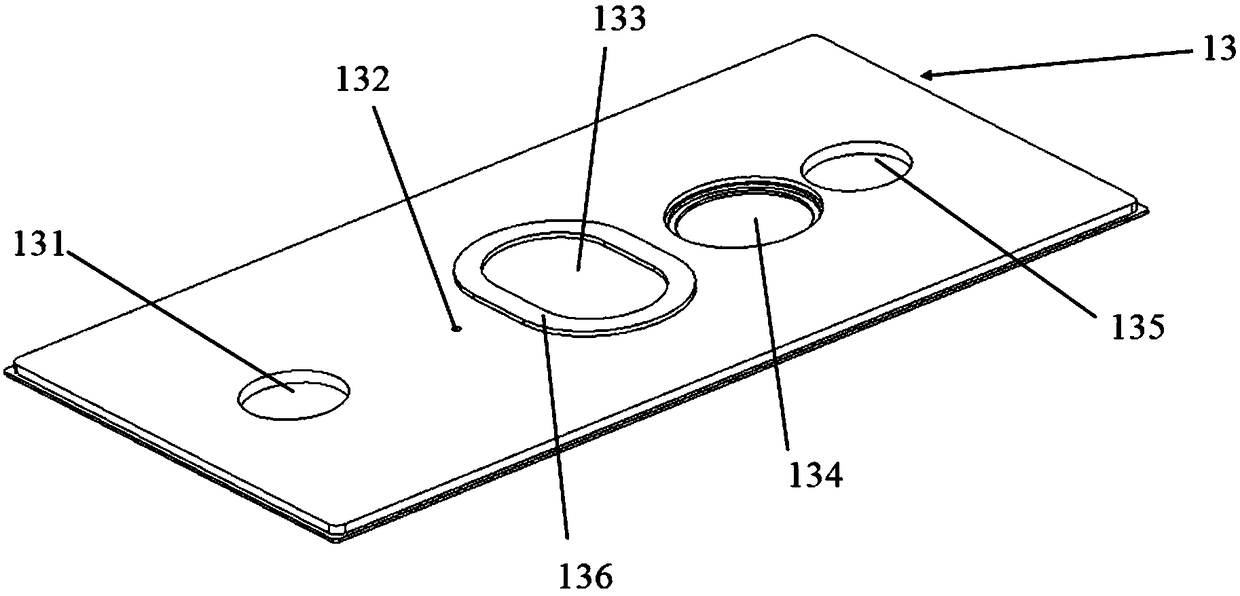

[0029] refer to Figure 1~4 , The secondary battery includes a secondary battery top cover 1, an electric cell 2 and a casing 3 for containing the electric cell, and the secondary battery electrolyte (not shown) soaking the electric cell is filled in the casing. The secondary battery top cover 1 includes a top cover sheet 13 , and a first electrode unit 11 , a second electrode unit 12 , a flip sheet 14 , a liquid injection hole 132 and an explosion-proof valve 137 arranged on the top cover sheet 13 . The top cover sheet 13 is provided with a flip sheet fixing hole 134, a first mounting hole 131, a second mounting hole 135 and an explosion-proof hole 133. The first electrode unit 11 is insulated and sealed in the first mounting hole 131, and the second electrode unit 12 The insulating seal is installed in the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com