Method and device for removing metallic material of high-speed conveyer belt bulk cargo

A conveyor belt and material metal technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of high-speed conveyor belt safety threats, time lag, and easy to be "thrown out", so as to improve equipment safety and The effect of delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

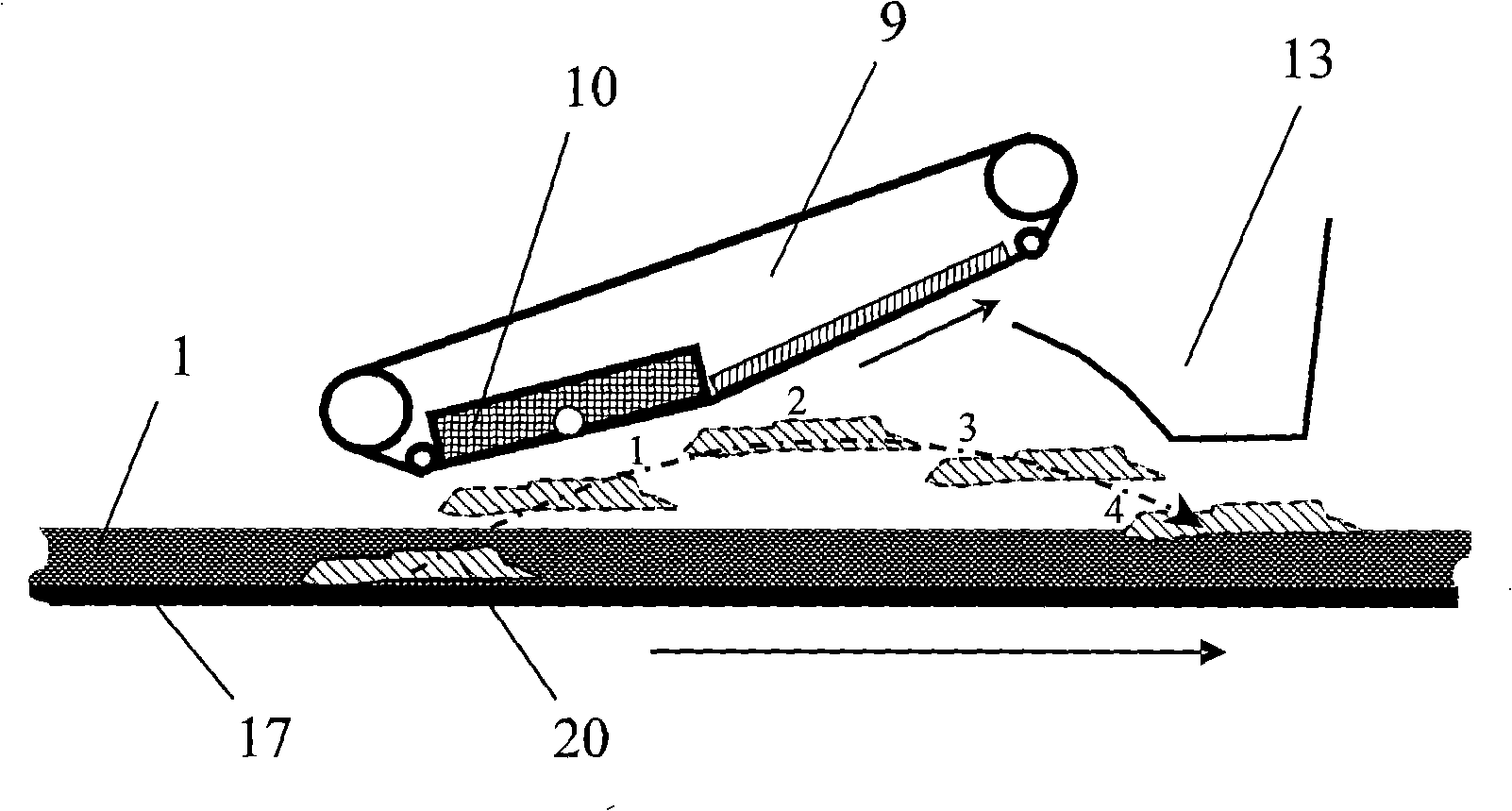

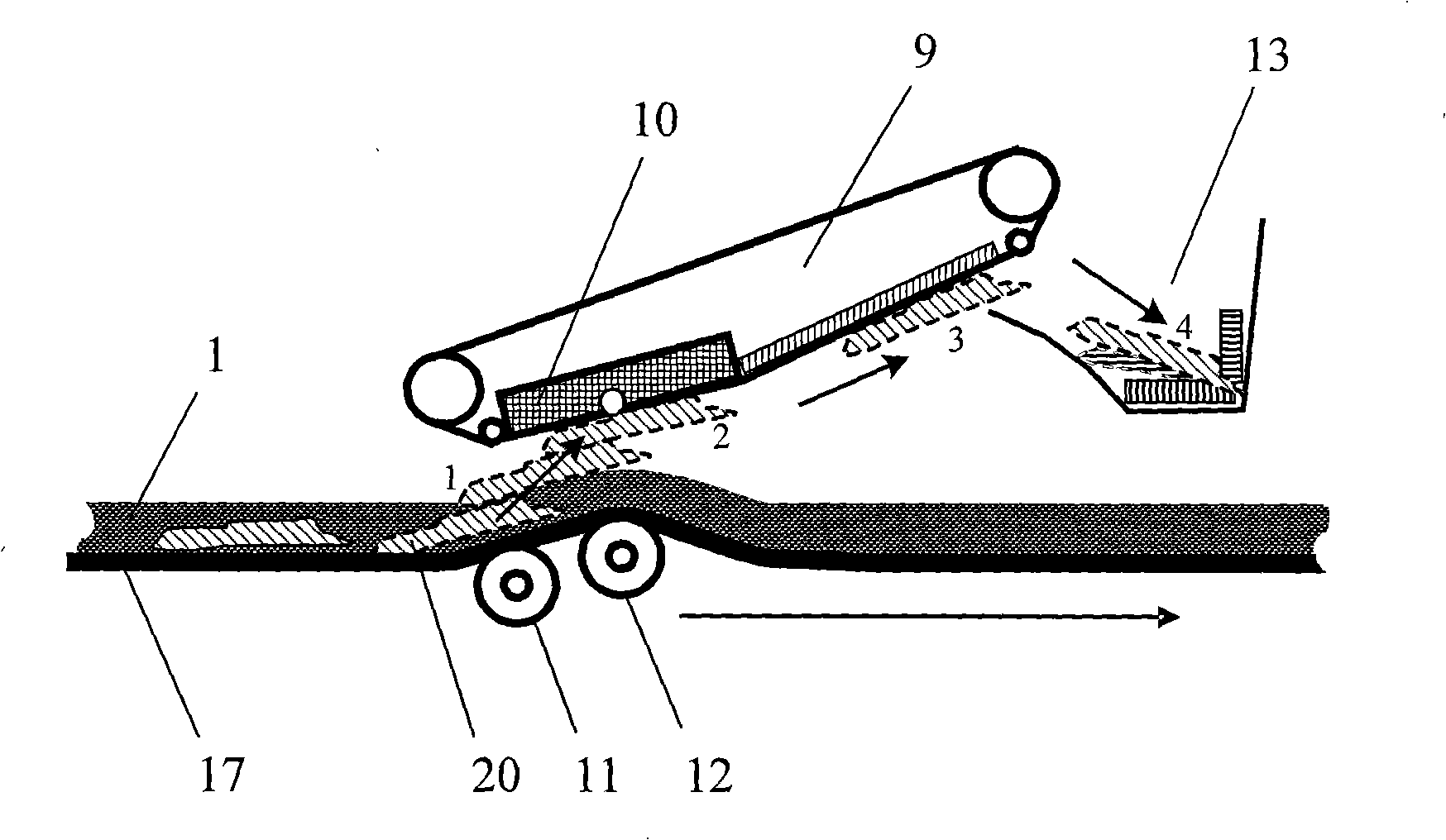

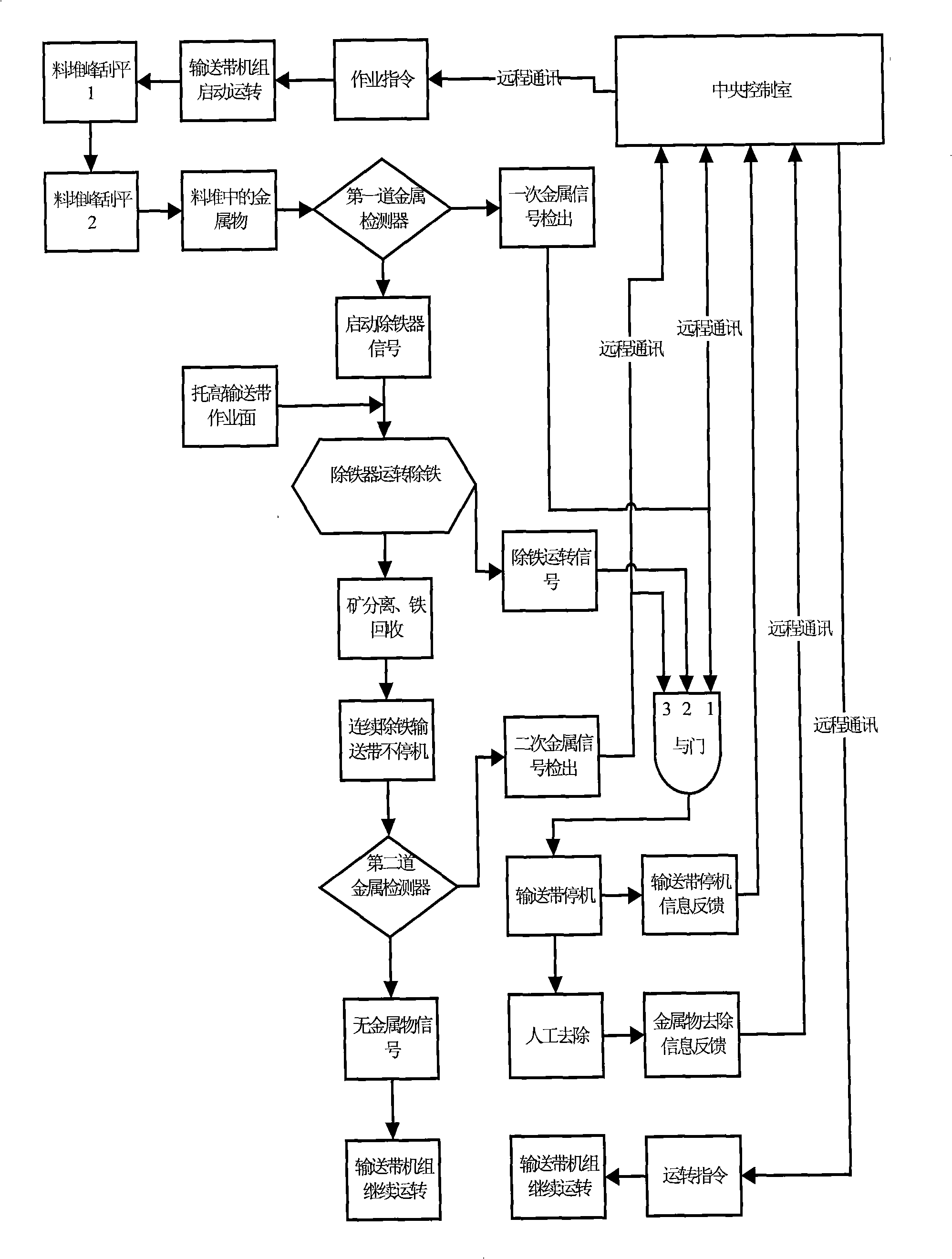

[0029] see image 3 , Figure 4 , a method for removing metal objects from bulk materials on high-speed conveyor belts. The "tip" is scraped off by two to three stockpile scrapers placed on the high-speed conveyor belt, and the metal objects in the conveyor belt stockpile pass through the first metal detector and give two signals at the same time: a metal removal signal Drive the iron remover, another signal is sent to the input terminal "1" of the AND gate circuit through a metal signal detection, and at the same time, the metal signal detection transmits the metal object information to the central control room through remote communication. After the iron remover is activated, the iron remover runs to remove iron. An adjustable conveyor belt support device is installed under the conveyor belt below the main electromagnet adsorption surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com