Preparation method of novel super-oleophylic and super-hydrophobic separation membrane

A separation membrane and super-lipophilic technology, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., to achieve the effects of easy amplification, high integration, and improved lipophilicity and hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 150 g of hexafluorobutyl acrylate and 250 g of hexafluorobutyl methacrylate, add 0.4 g of azobisisobutyronitrile, add 200 g of toluene, and pass nitrogen gas for 30 minutes, then heat the reaction at 70°C for 5 hours. Take it out, deposit it in deionized water, and dry it in vacuum to obtain a hydrophobically modified polymer.

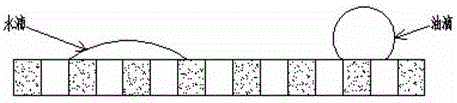

[0029] The hydrophobically modified polymer was dissolved in tetrahydrofuran to prepare a 5% hydrophobically modified solution. Take a flat polypropylene separation membrane with a separation pore diameter of 10 μm, soak the separation membrane in the hydrophobic modification solution for 20 minutes, take it out, dry it, and repeat the process 3 times. A hydrophobically modified polypropylene separation membrane is obtained. The water contact angle of the hydrophobically modified membrane was 155°, and the oil contact angle was 0°.

[0030] The aqueous crude product is taken for filtration. The filtration pressure is 0.2MPa, and the wate...

Embodiment 2

[0032] Take 350 g of 2,2,2-trifluoroethyl methacrylate and 250 g of dodecafluoroheptyl methacrylate, add 0.5 g of azobisisoheptanonitrile, add 400 g of dimethyl phthalate, and pass in nitrogen gas 30min, then heated for reaction at 75°C, reacted for 4.5h, took it out, deposited it in deionized water, and dried it in vacuum to obtain a hydrophobically modified polymer.

[0033] The hydrophobically modified polymer was dissolved in chloroform to make a 5% hydrophobically modified solution. Take a flat polyacrylonitrile separation membrane with a separation pore diameter of 20 μm, soak the separation membrane in the hydrophobic modification solution for 20 minutes, take it out, dry it, and repeat it twice. A hydrophobically modified polypropylene separation membrane is obtained. The water contact angle of the hydrophobically modified membrane was 150°, and the oil contact angle was 0°.

[0034] The aqueous crude product is taken for filtration. The filtration pressure is 0.2MP...

Embodiment 3

[0036] Take 350g of dodecafluoroheptyl acrylate and 250g of styrene respectively, add 0.5g of azobisisoheptanonitrile, add 400g of dimethyl phthalate, pass nitrogen gas for 30min, and then heat the reaction, the heating temperature is 75°C, the reaction After 10 hours, it was taken out, deposited in deionized water, and vacuum-dried to obtain a hydrophobically modified polymer.

[0037] The hydrophobically modified polymer was dissolved in chloroform to make a 5% hydrophobically modified solution. Take a flat polysulfone separation membrane with a separation pore diameter of 0.5 μm, soak the separation membrane in the hydrophobic modification solution for 20 minutes, take it out, dry it, and repeat the process 3 times. A hydrophobically modified polypropylene separation membrane is obtained. The water contact angle of the hydrophobically modified membrane was 157°, and the oil contact angle was 0°.

[0038] The aqueous crude product is taken for filtration. The filtration p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com