Patents

Literature

34results about How to "Good business effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

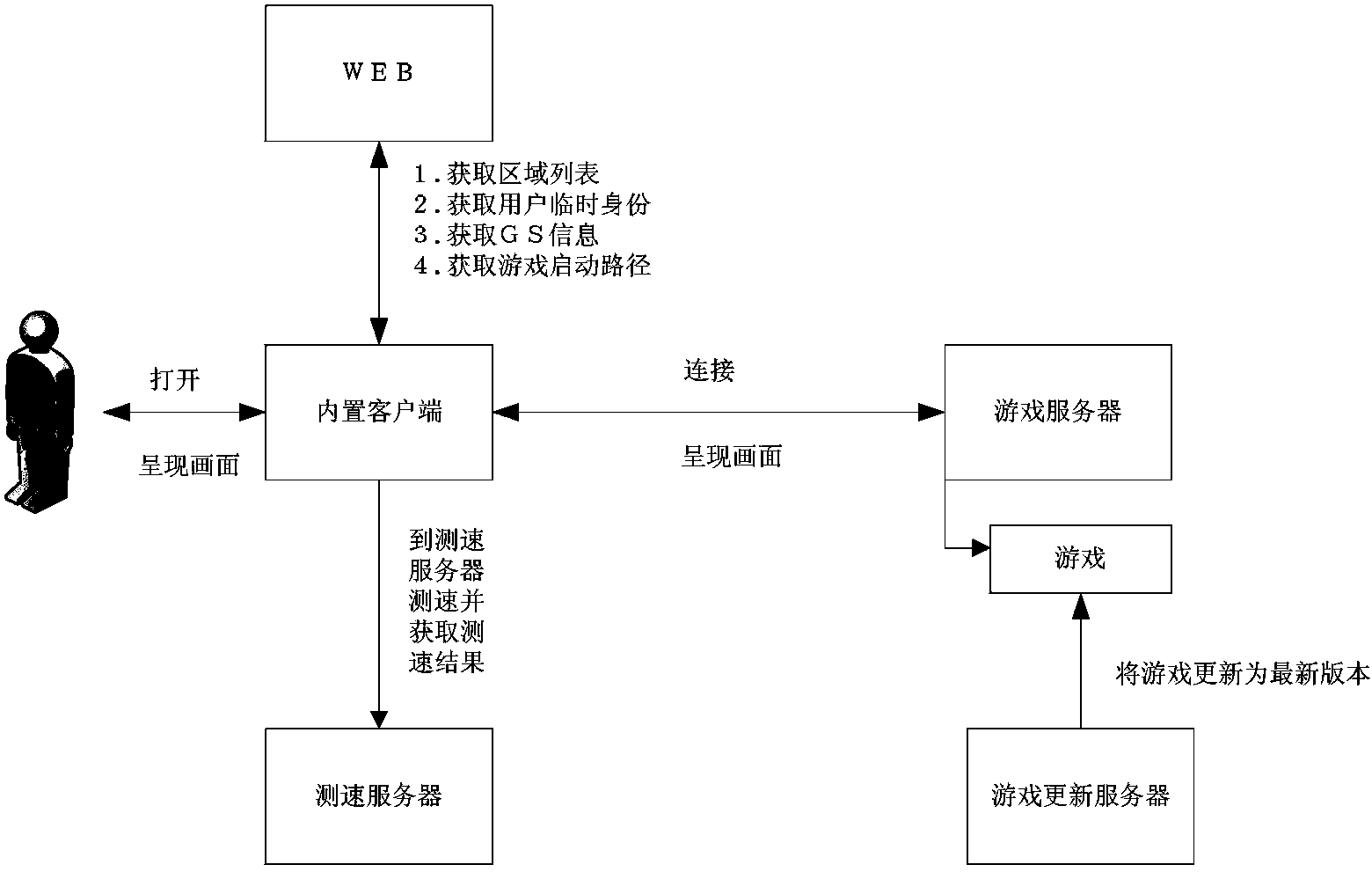

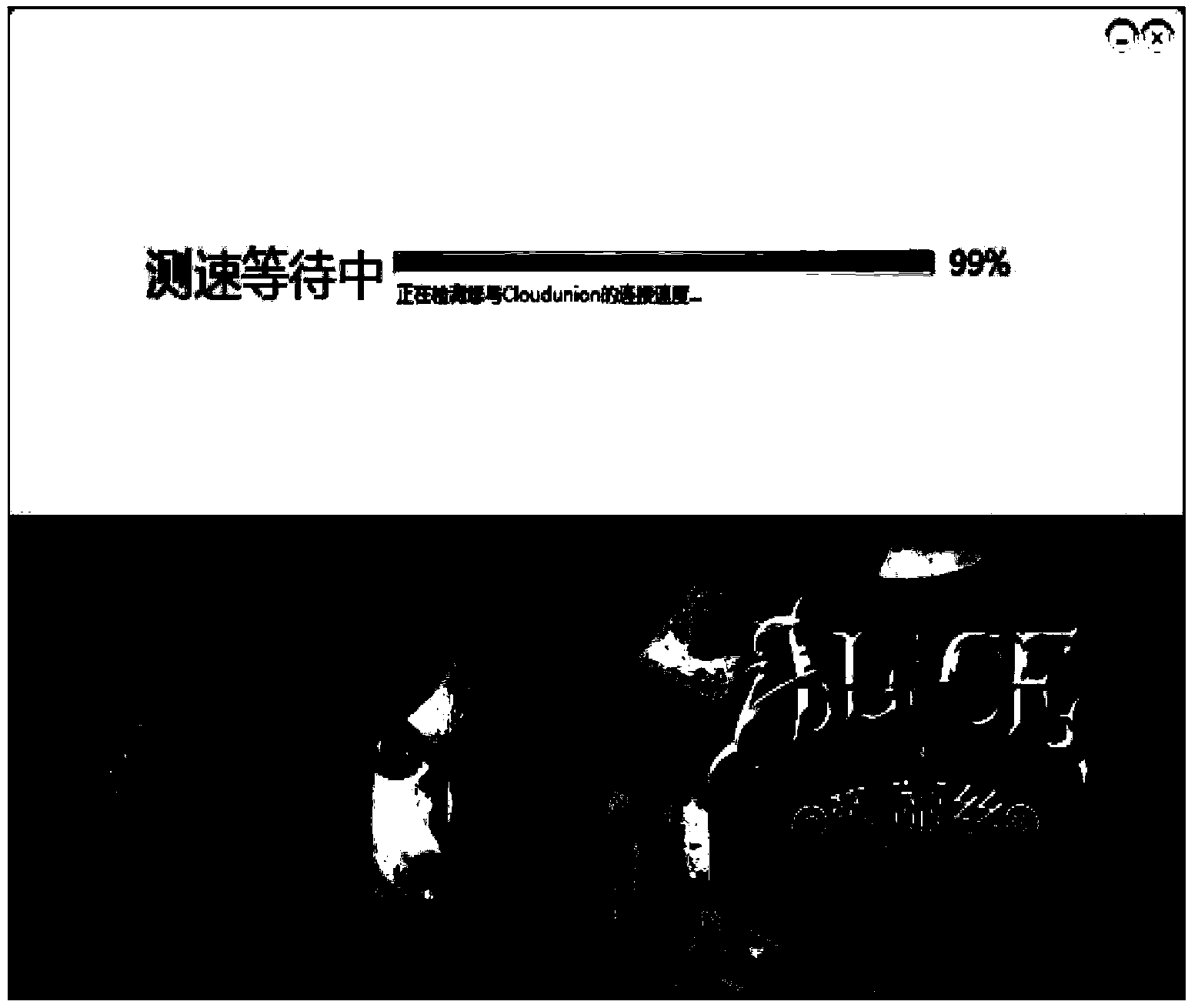

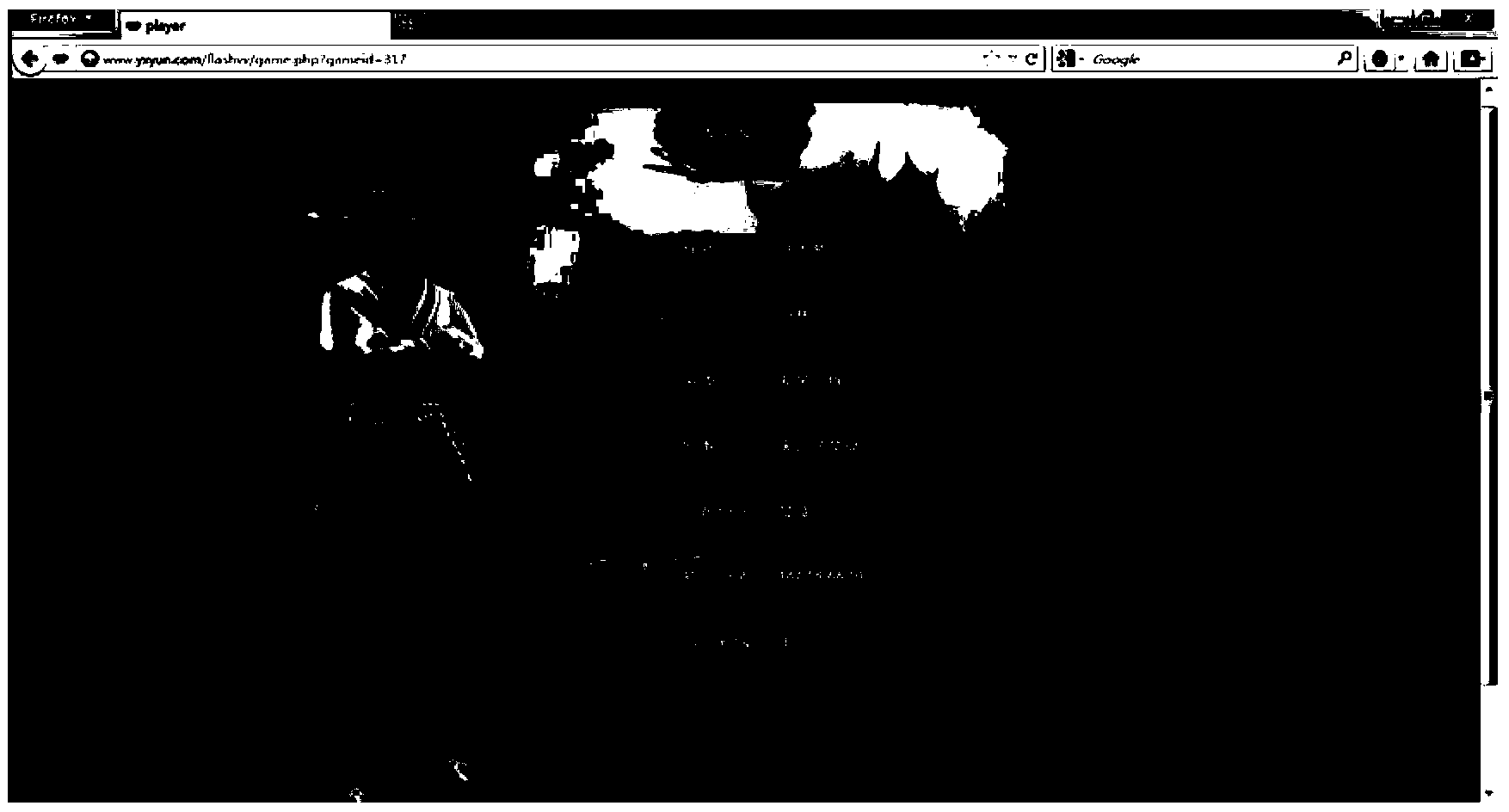

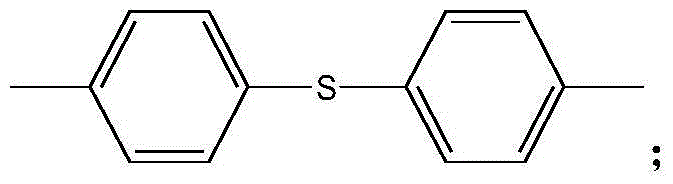

Method for achieving online game operation based on cloud computing

The invention provides a method for achieving online game operation based on cloud computing. The method comprises the following steps: a built-in client of a browser is started on a user terminal to build a request for WEB of a cloud service system to request a list of currently opened zones, and the list is shown for a user; speed measurement is conducted on a selected zone, and temporary identity of the current user is requested; when a speed measurement result meets the requirements, the built-in client carries the speed measurement result to request for the start of a server of a currently available game to the WEB, game image and sound and other information are sent to the built-in client, the built-in client loads the game interface sound and shows the game interface sound for the user, and the user starts the game operation; when the game is played to a pre-set level, a game application program conveys a game-off message to the WEB; a dialog box is popped up to prompt the user to download a game client, and the built-in client of the browser is disconnected with the server at the moment. Through the adoption of the method, the user can be guaranteed to smoothly enter a free-to-try game, so that the user can enter the game once.

Owner:北京千禧光年信息技术有限公司

Method for smelting stainless steel mother liquor with furnace wall carbon-oxygen spray gun in arc furnace

ActiveCN102443678AFast meltingShorten smelting timeProcess efficiency improvementElectric furnaceScrapChemical energy

The invention discloses a method for smelting stainless steel mother liquor with a furnace wall carbon-oxygen spray gun in an arc furnace. The method is characterized in that an eccentric bottom tapping arc furnace provided with the furnace wall carbon-oxygen spray gun is used; during smelting, the furnace wall carbon-oxygen spray gun is used to preheat and cut metallic charge and perform oxygen blowing and decarburization in the oxidation period; by using the furnace wall carbon-oxygen spray gun to provide chemical energy and preheat and cut scrap steel, the melting rate can be increased, the smelting time, and electrode consumption and smelting power consumption can be reduced; a burner adopts a coherent jet oxygen supply mode to blow oxygen and decarburize so that the utilization rate of oxygen is high and the oxidation quantity of chromium is low; and the smelting time and the metallic charge consumption are reduced. The method uses the furnace wall carbon-oxygen spray gun to smelt stainless steel, thus the consumption of oxygen lances can be reduced, the production cost can be significantly lowered and the labor intensity of workers can be significantly reduced.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

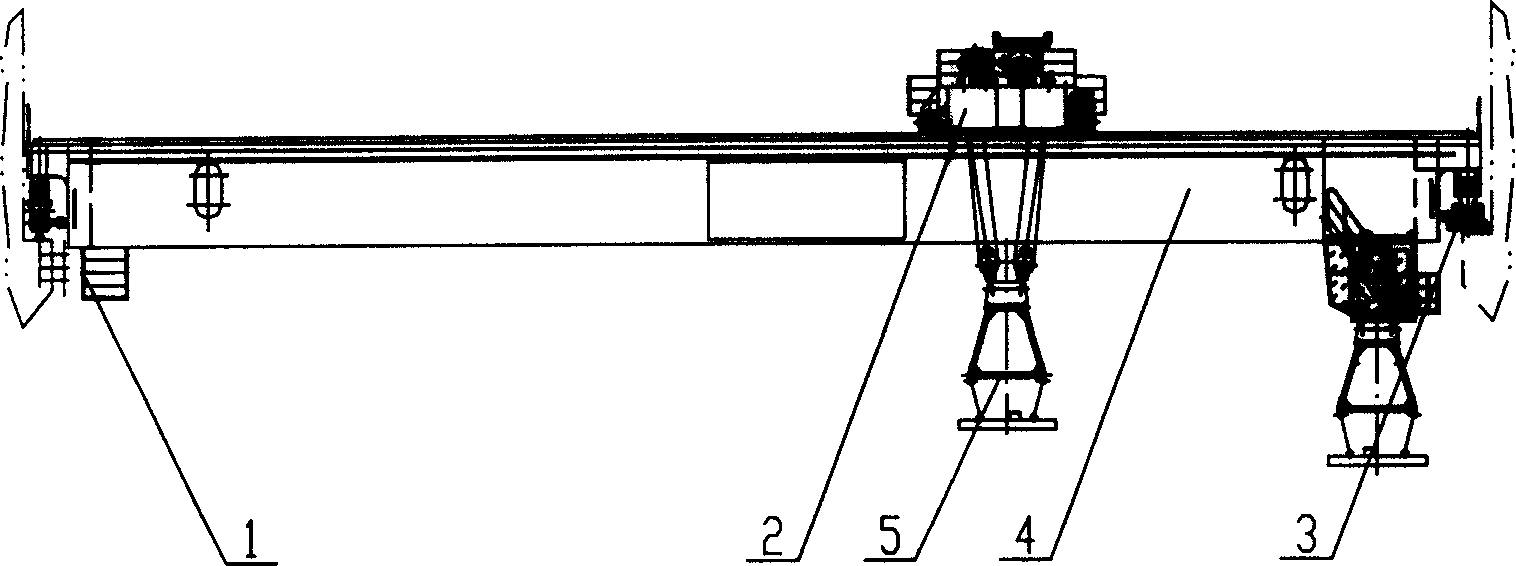

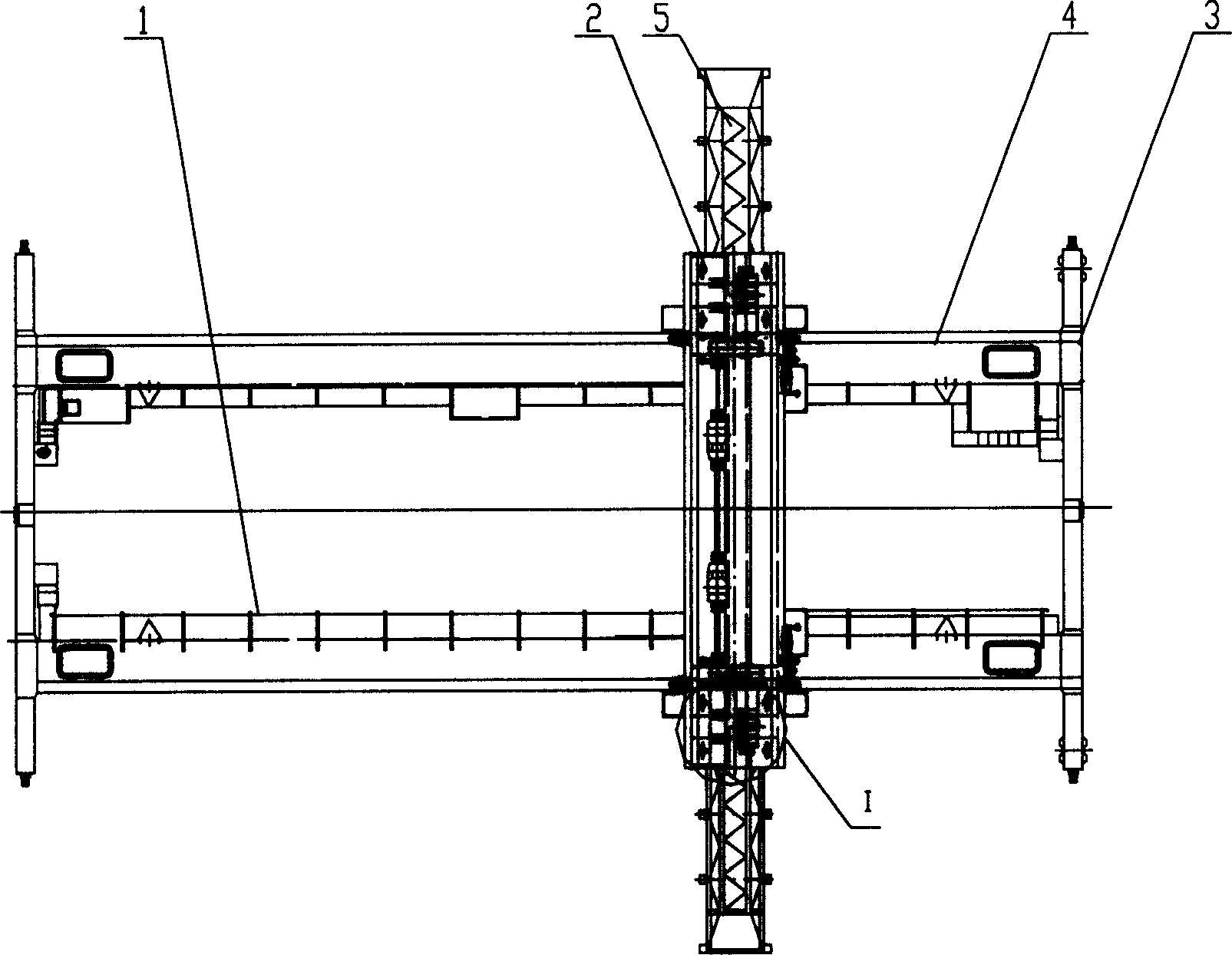

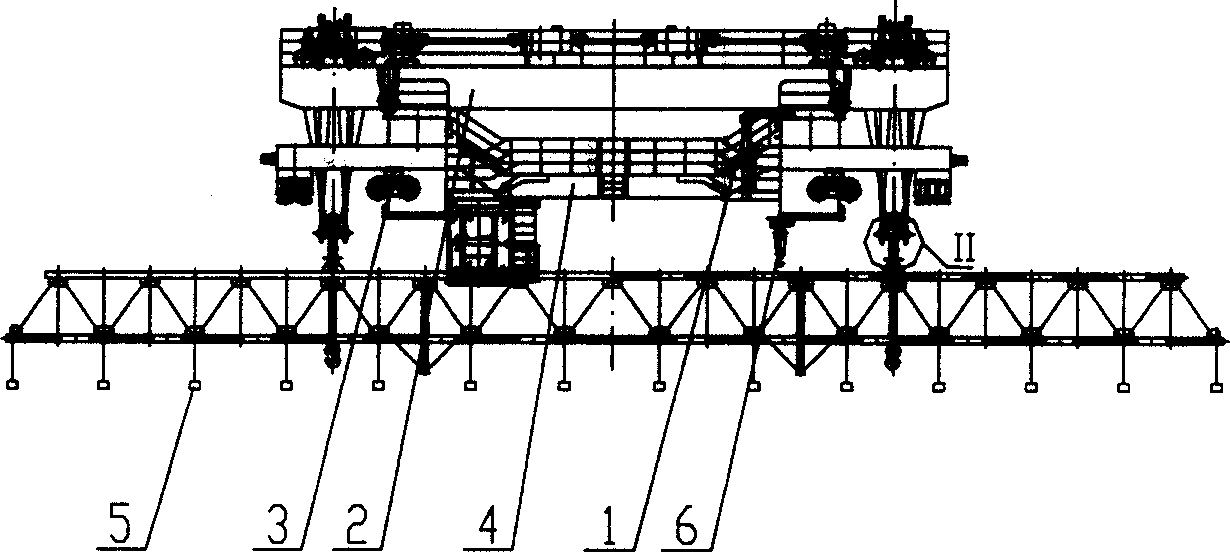

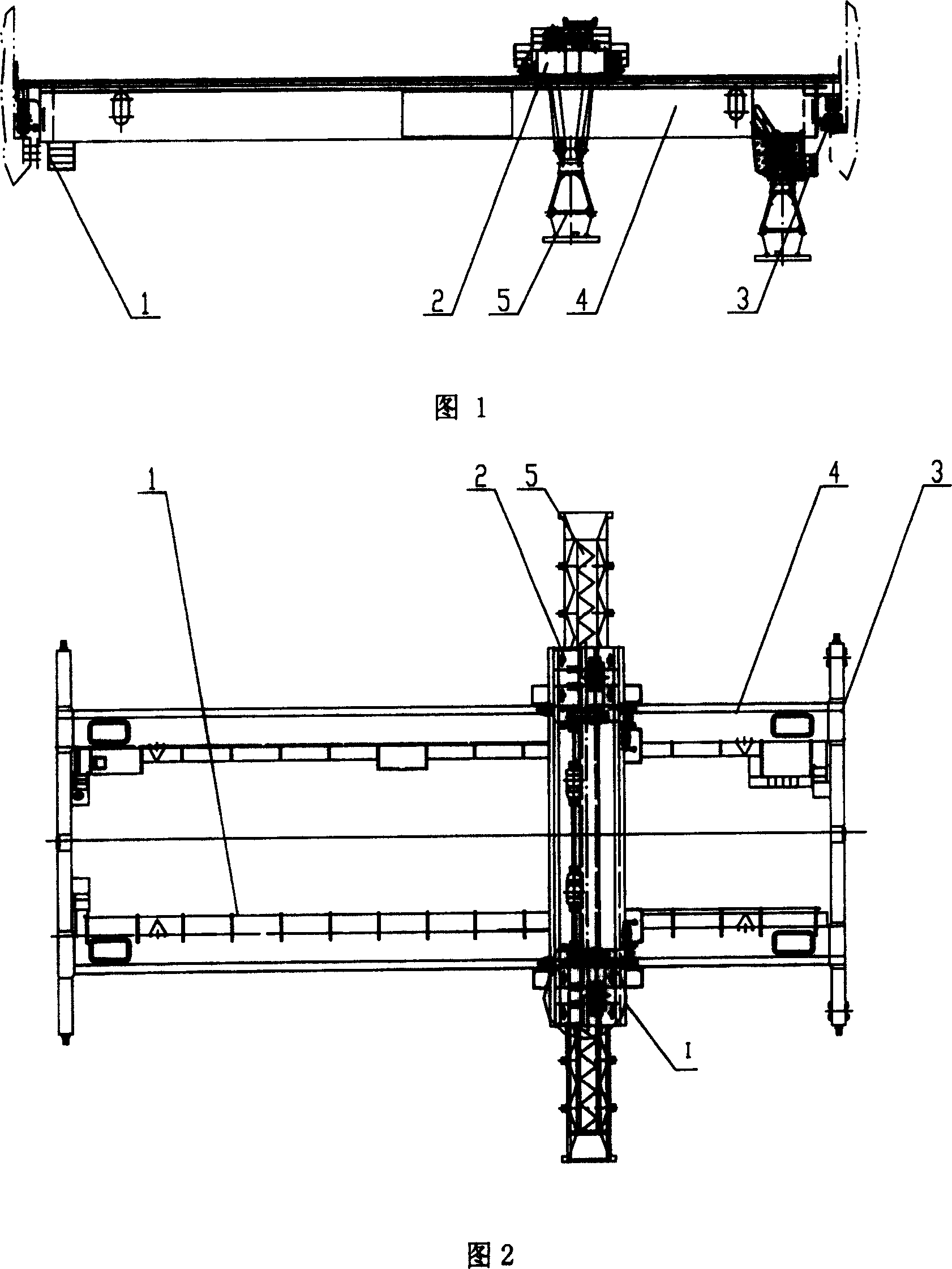

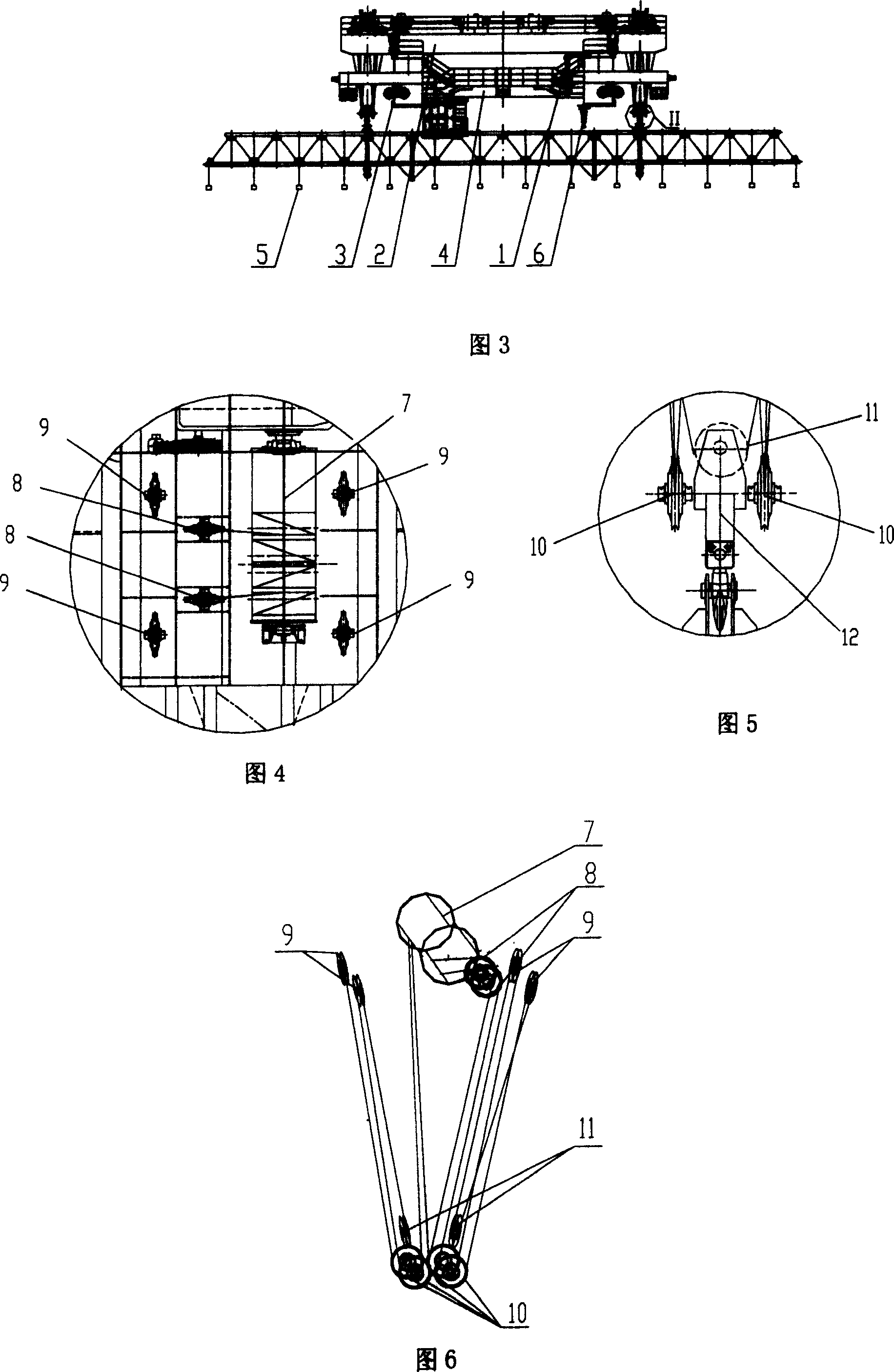

Method for preventing swinging of beam hanging and steel plate during starting and braking of electromagnetic beam hanging crane

A method for preventing the swinging of pylon and steel plate when a pylon-type electromagnetic hoister is started or stopped features that two steel cables used between the bogie and hook of lifting unit are respectively wound on pulleys to a dual-reverse-splayed system to effectively provent said swinging.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

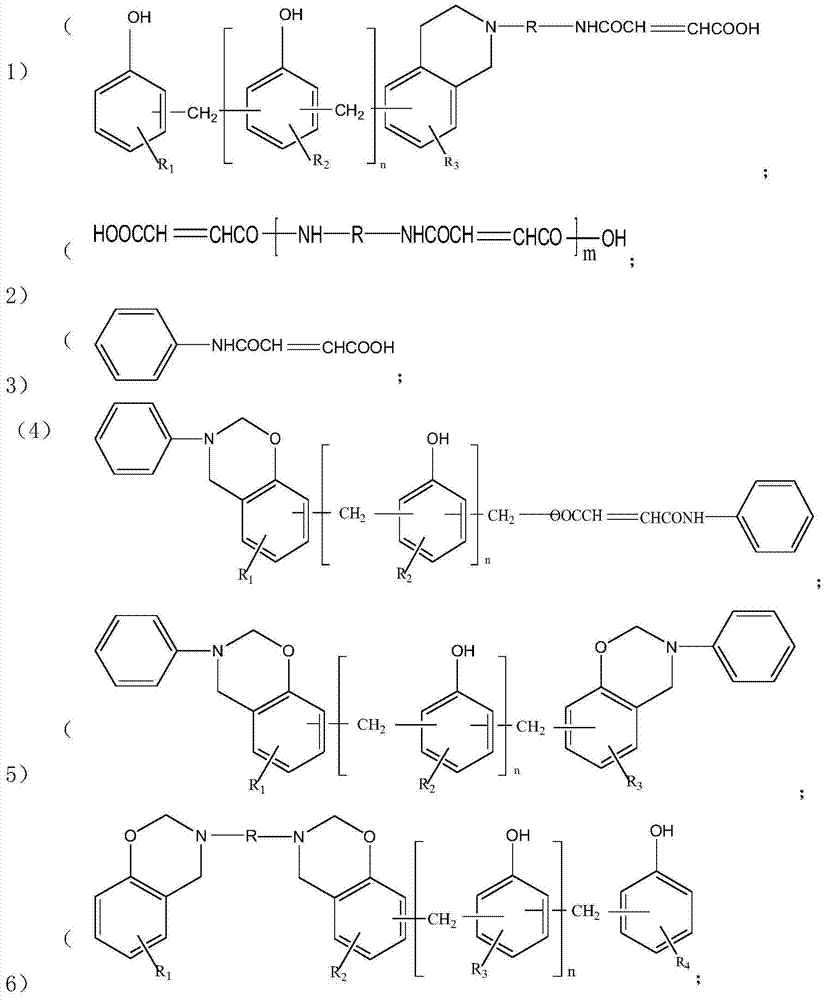

Preparation method of polybenzoxazine-imine glass fiber cloth laminated board

ActiveCN103496245AImprove brittlenessImprove heat resistanceSynthetic resin layered productsLaminationAdhesiveAccelerant

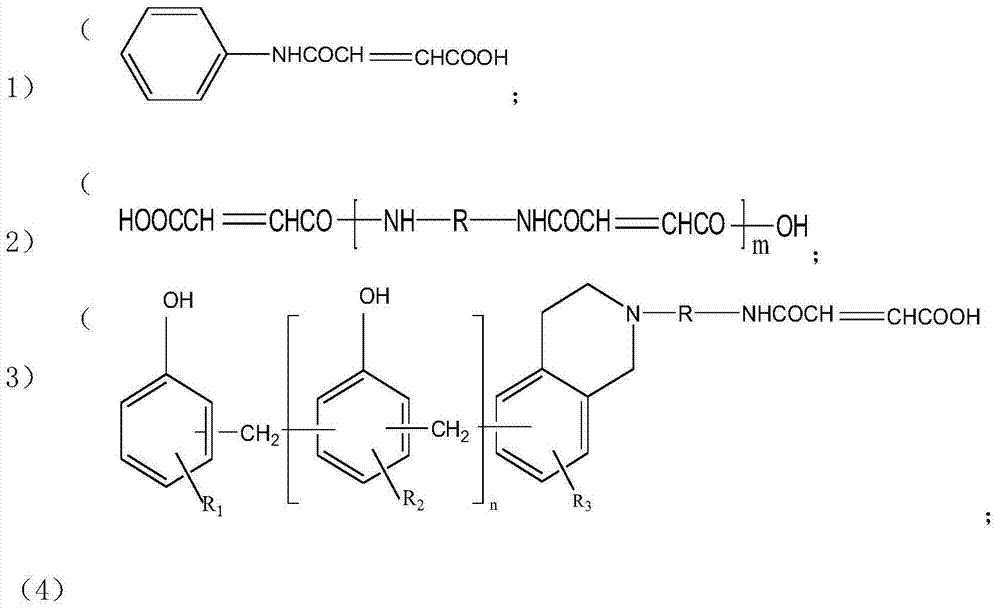

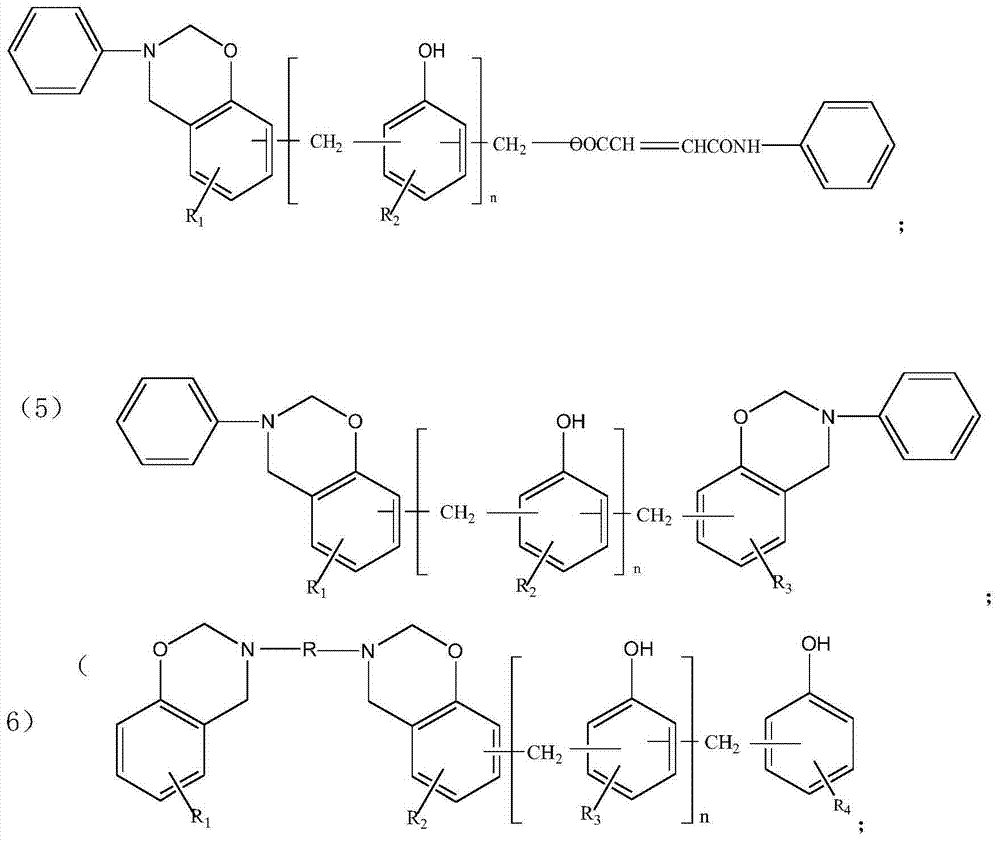

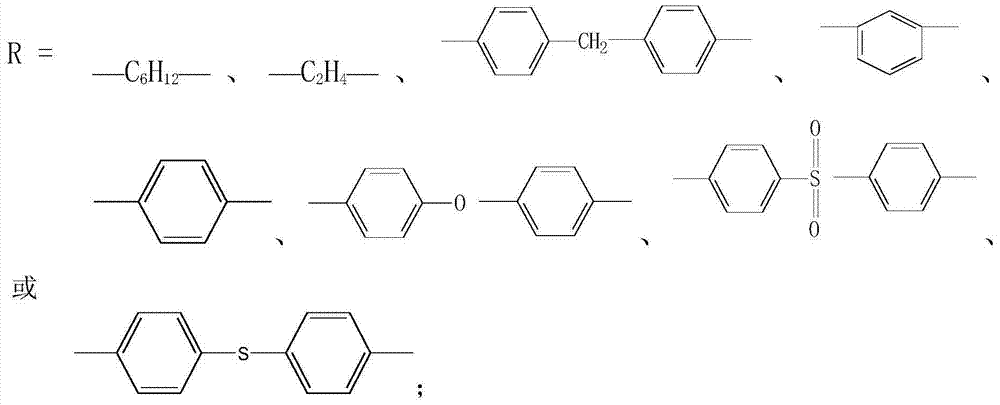

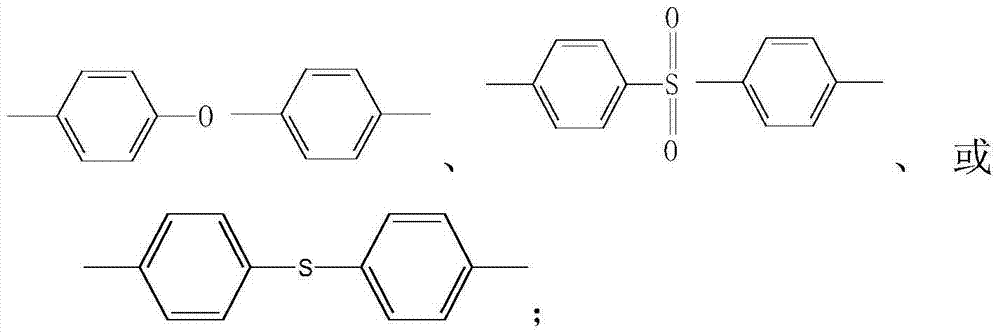

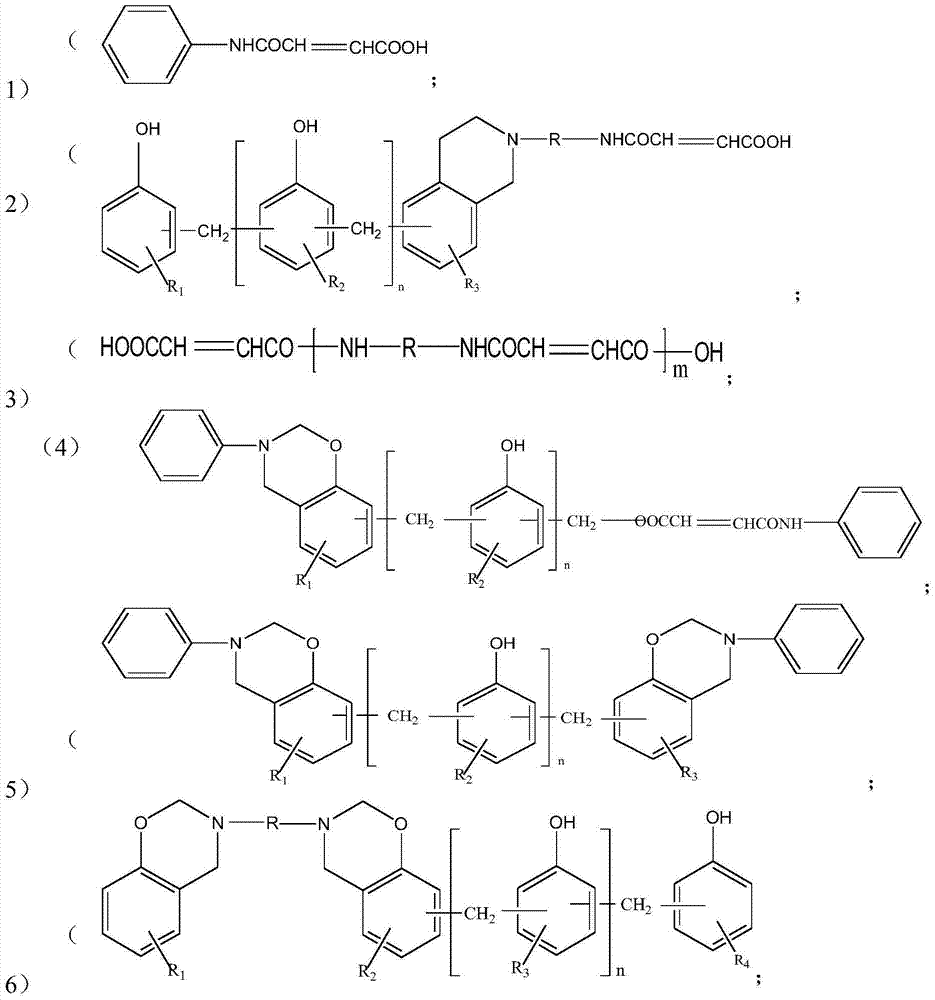

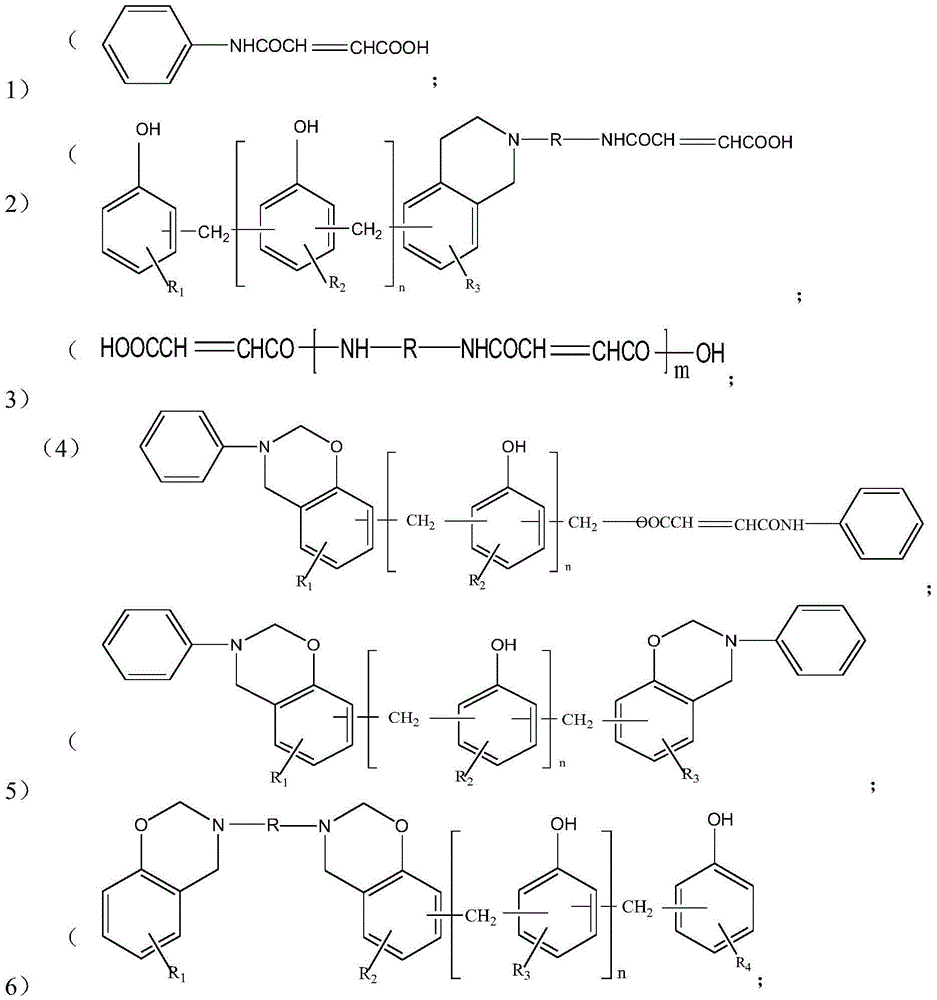

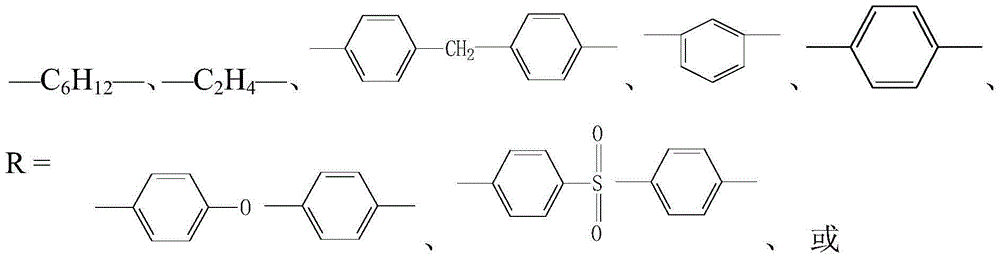

The invention discloses a preparation method of a polybenzoxazine-imine glass fiber cloth laminated board. The preparation method is characterized by comprising the steps of adding an amine compound, maleic anhydride and 3 / 4 of methylbenzene into a reactor, heating to 70-95 DEG C to react for 1-2h, cooling to 5-25 DEG C, adding a water solution of formaldehyde, controlling the temperature to not be higher than 30 DEG C to react for 0.5-2h, adjusting the pH value to 6-8, adding a phenolic compound and residual benzene, reacting at the temperature of 80-100 DEG C for 2-5h, standing for layering, adding acetone into an organic phase, stirring and mixing to obtain a benzoxazine-maleic amide resin solution; mixing the benzoxazine-maleic amide resin solution and an accelerant to prepare an adhesive; coating the adhesive on glass fiber cloth through a glue spreader, roasting to obtain pre-impregnated glass fiber cloth, tailoring the pre-impregnated glass fiber cloth to the size required by a product, and carrying out hot press molding to obtain the polybenzoxazine-imine glass fiber cloth laminated board. The polybenzoxazine-imine glass fiber cloth laminated board is suitable for being used as an electrical insulating material or structural composite in the fields such as motors, electrical appliances, military industry, petroleum and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

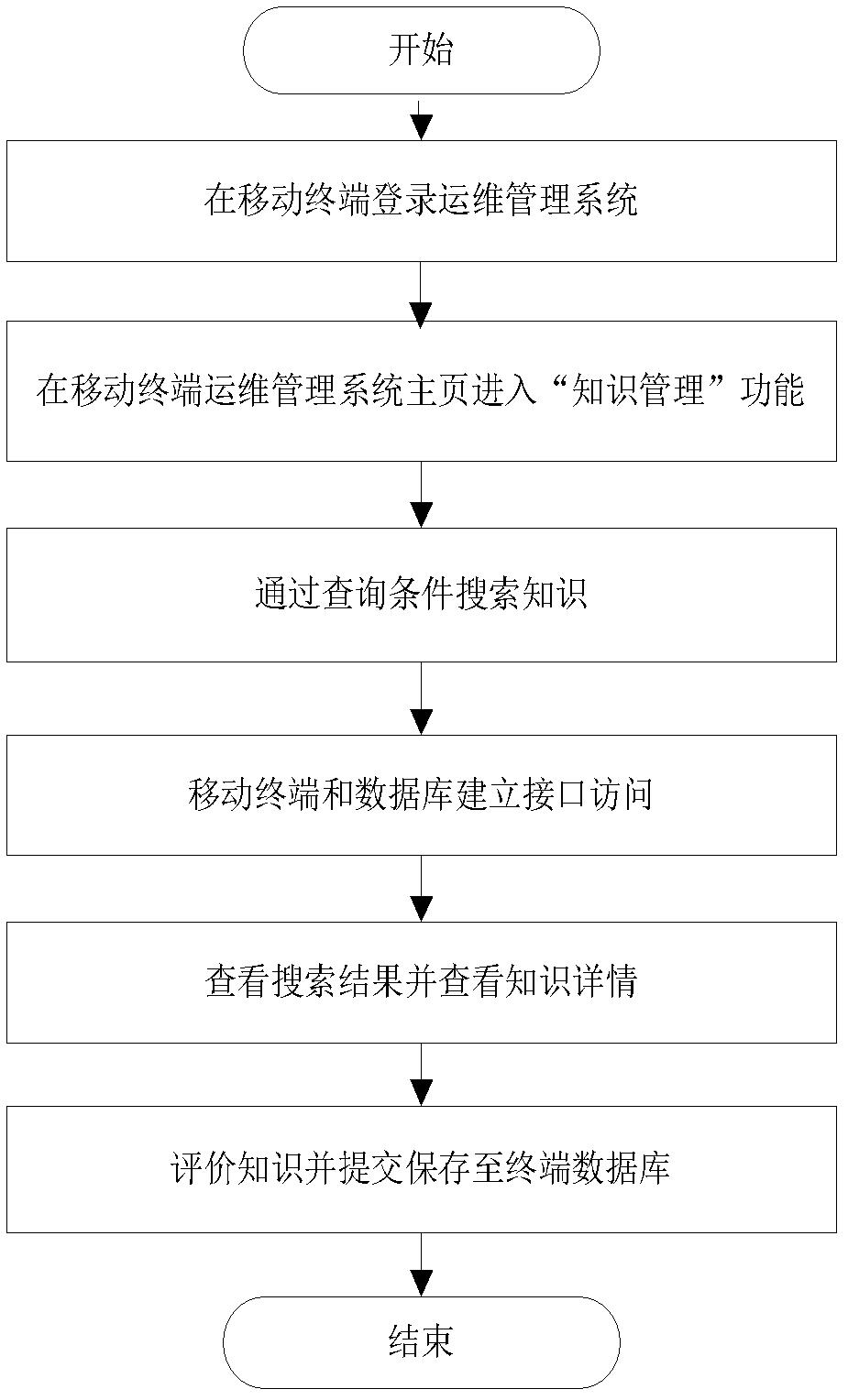

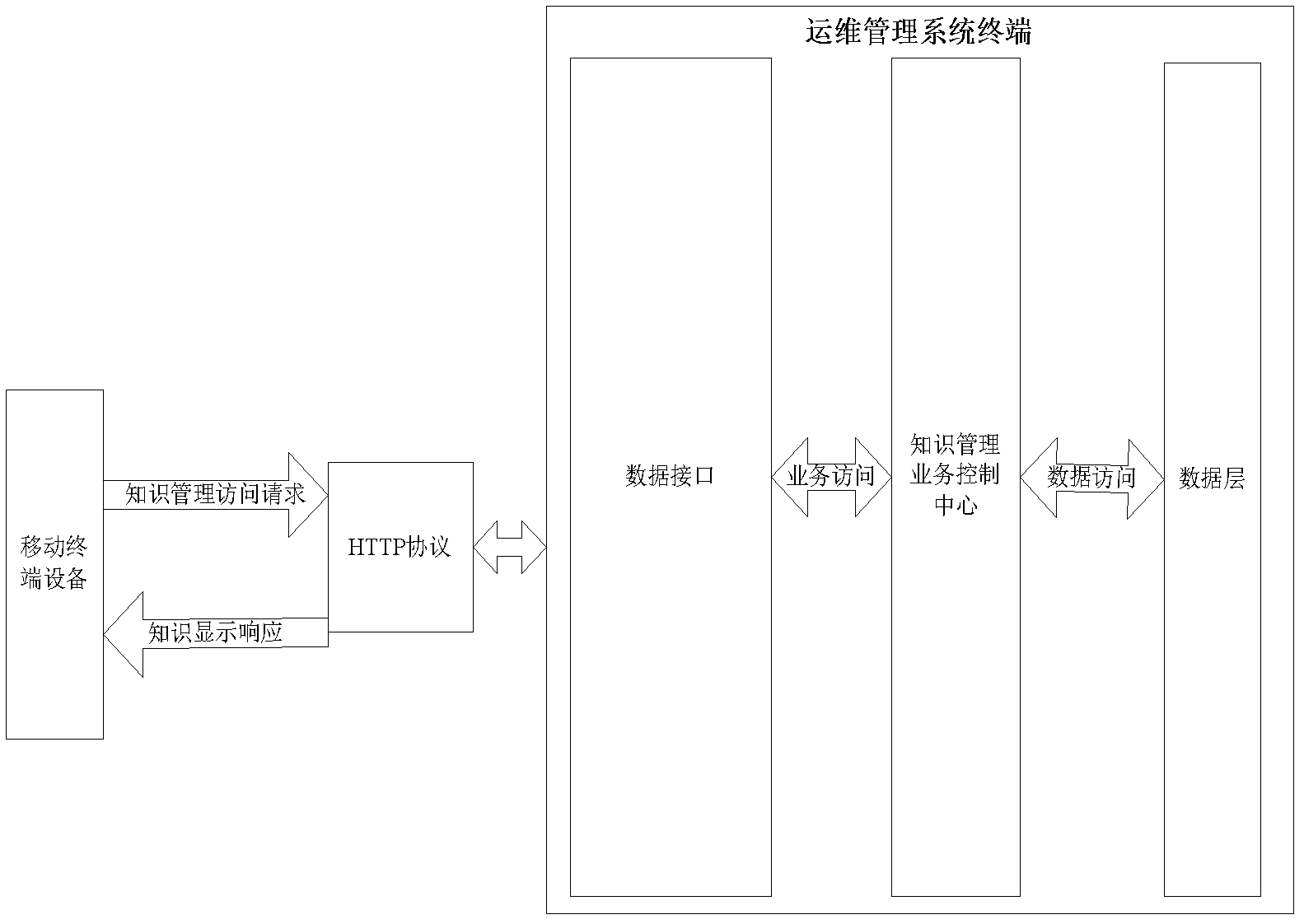

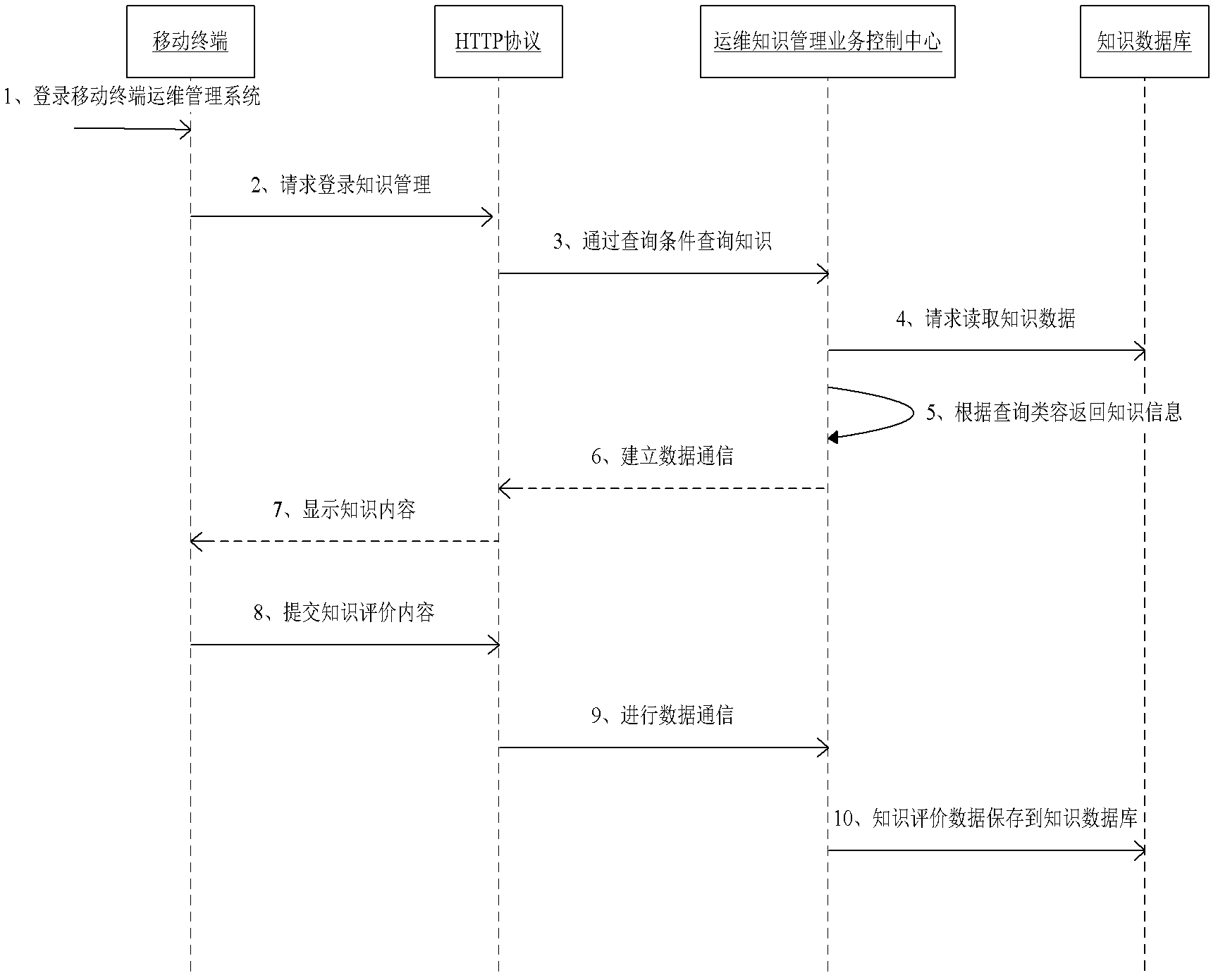

Operation and maintenance knowledge management system based on mobile terminal

InactiveCN103186627AEasy to transmit in real timeImprove service levelSpecial data processing applicationsManagement systemMaintenance management

The invention discloses an operation and maintenance knowledge management system based on a mobile terminal. A method comprises the following main steps: 1) logging in the operation and maintenance management system through the mobile terminal; 2) entering a 'knowledge management' function from a home page of the operation and maintenance management system based on the mobile terminal; 3) querying knowledge through a query condition; 4) building an interface for accessing a database according to the obtained information by the mobile terminal; 5) viewing a search result on the mobile terminal, and selecting and viewing related knowledge details; and 6) when viewing the knowledge, evaluating the knowledge on the mobile terminal, submitting evaluation content, and storing related information to a terminal database. By the method, an operation and maintenance staff can get a better operational guidance in the specific operation, maintenance and implementation processes, thereby lowering the operation risk of the operation, maintenance and implementation processes and improving the competitiveness of the business service level.

Owner:勤智数码科技股份有限公司

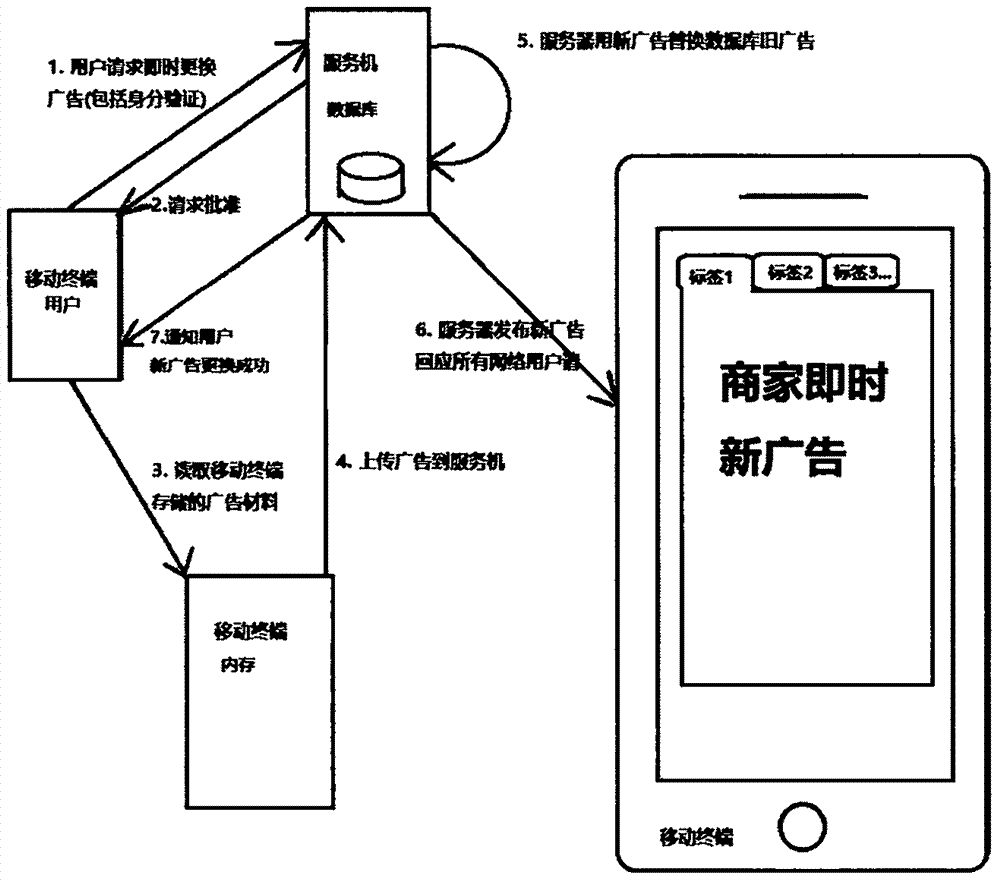

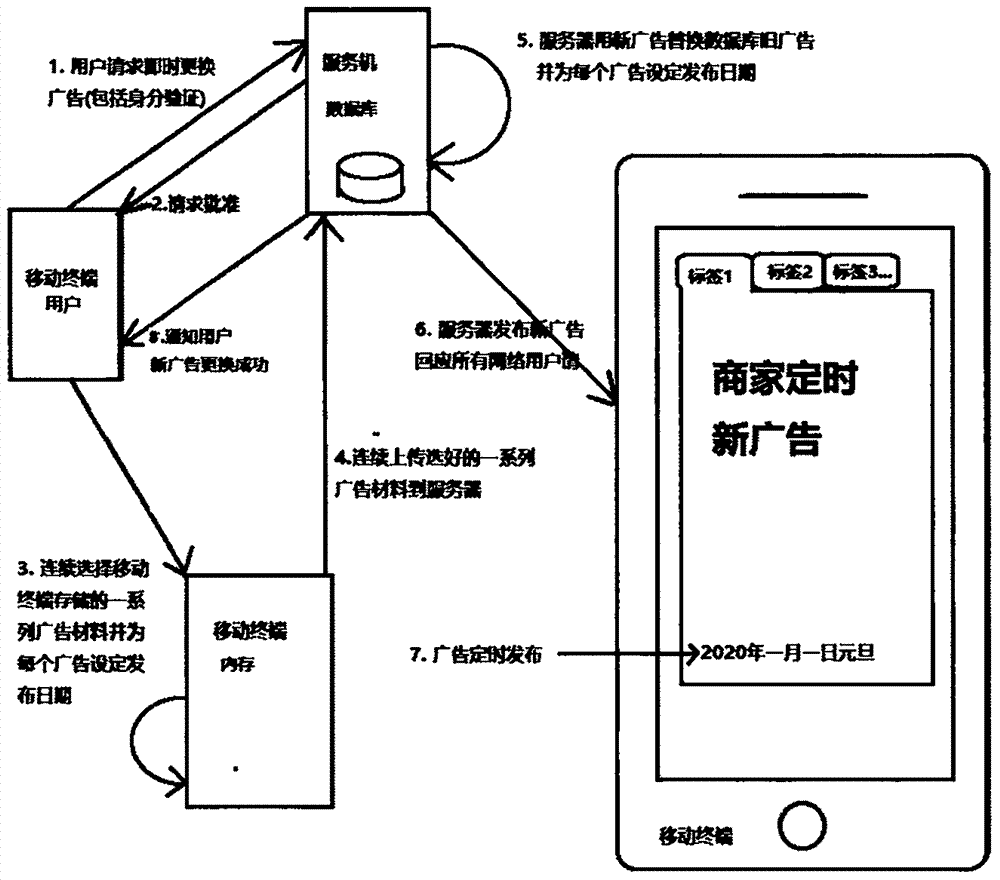

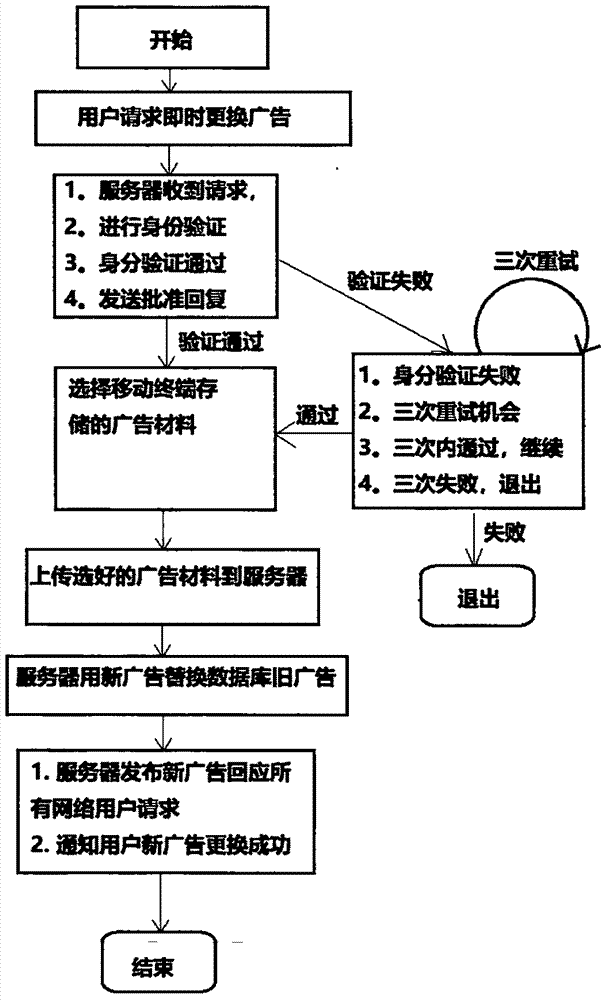

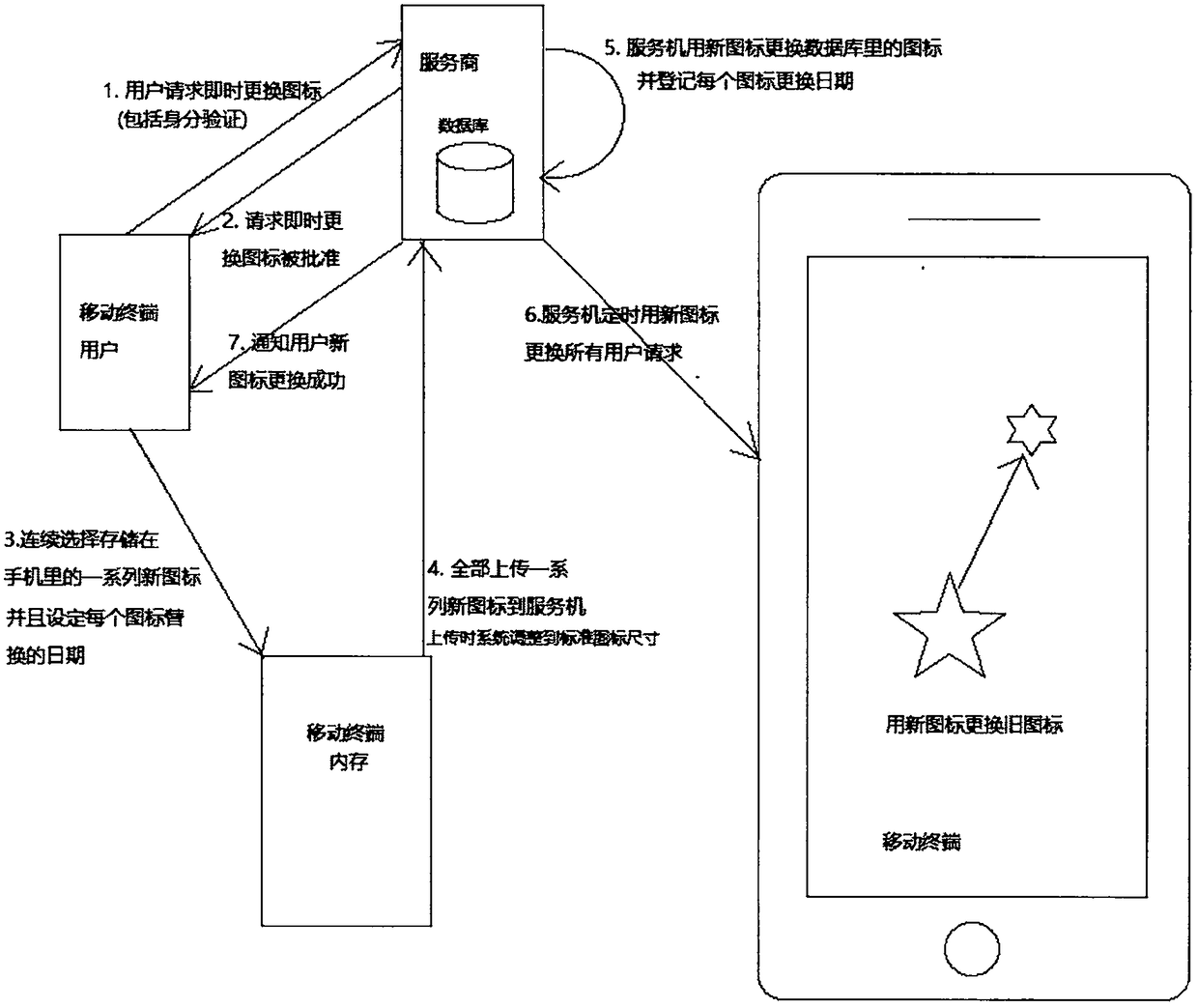

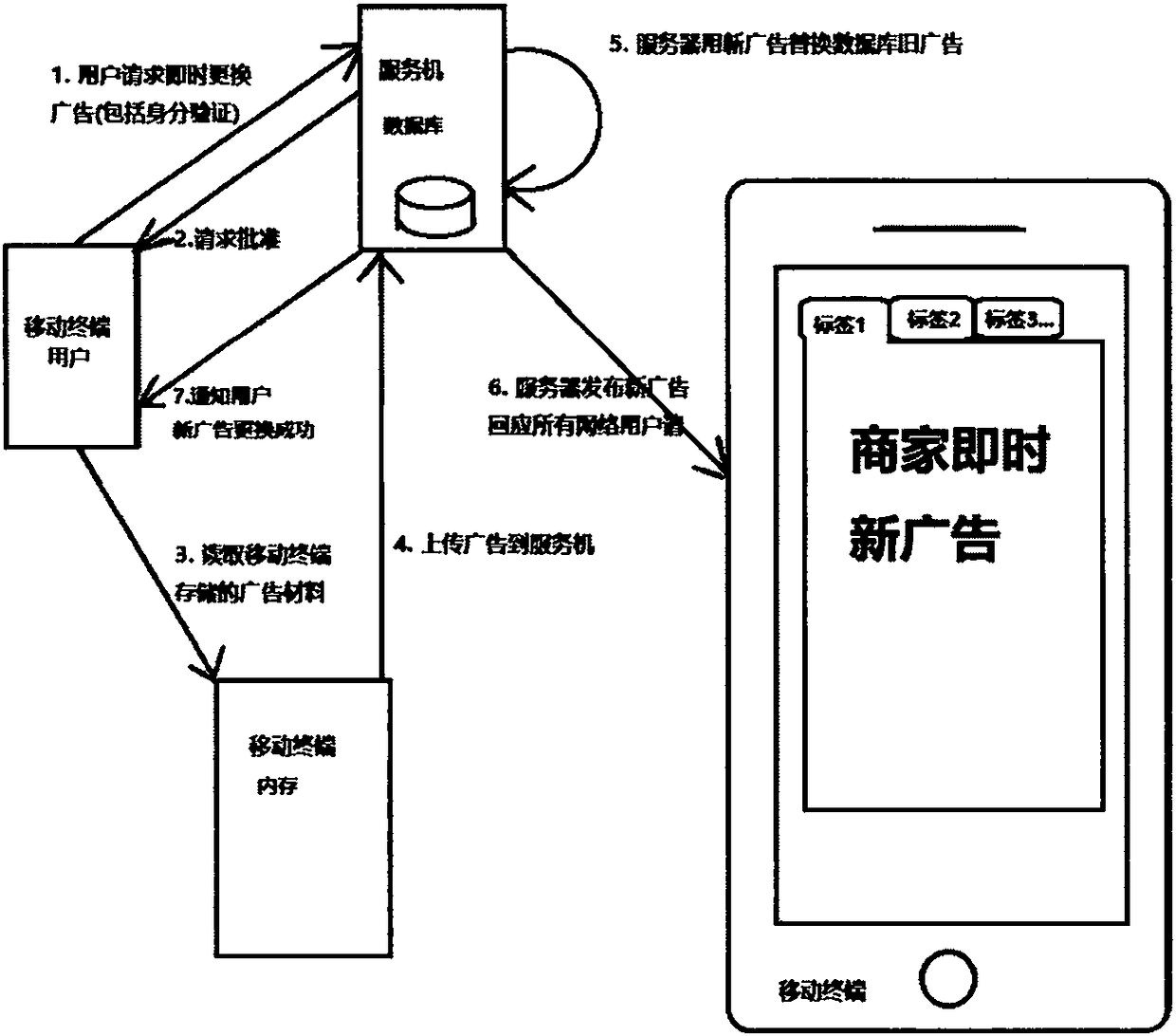

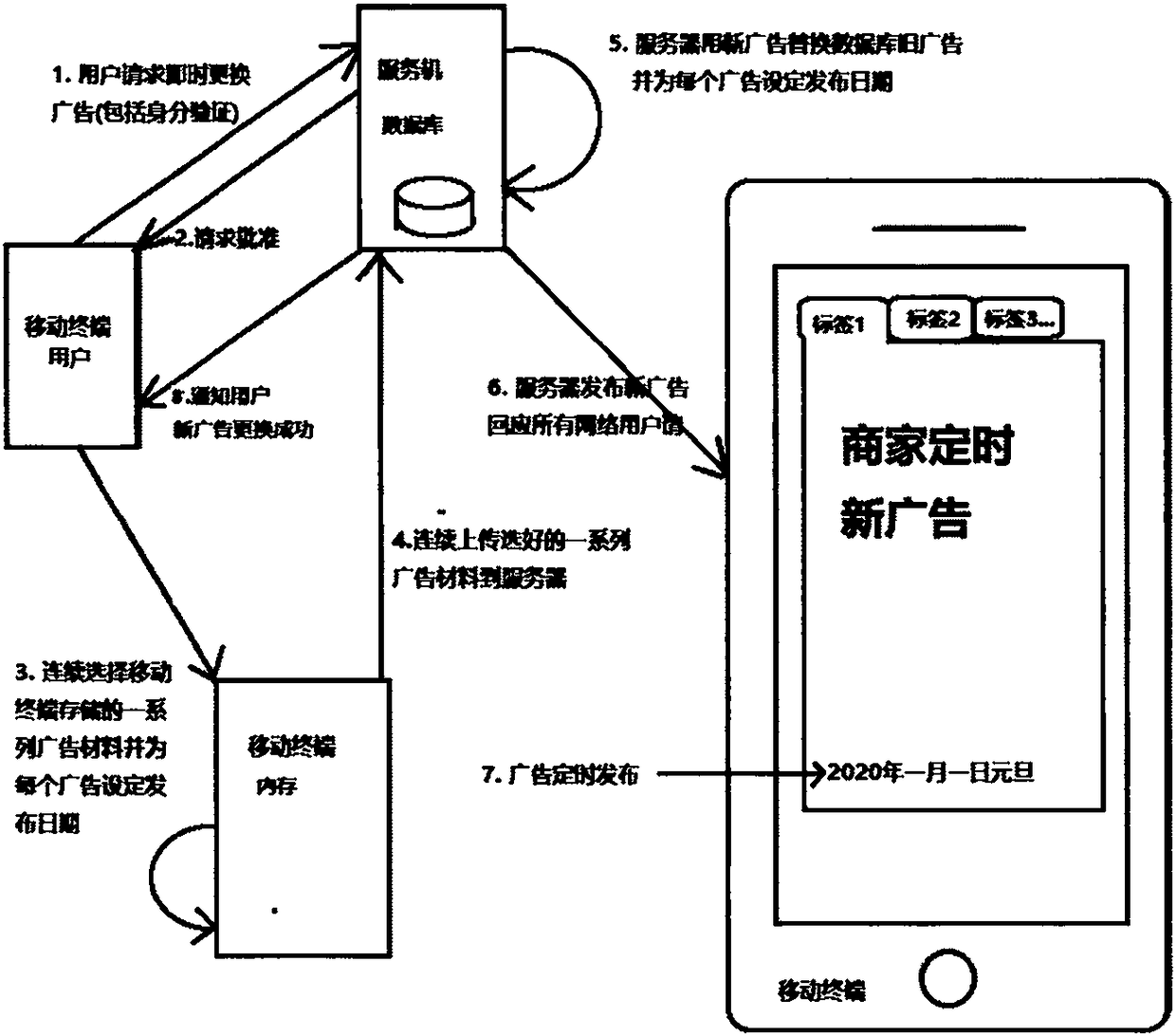

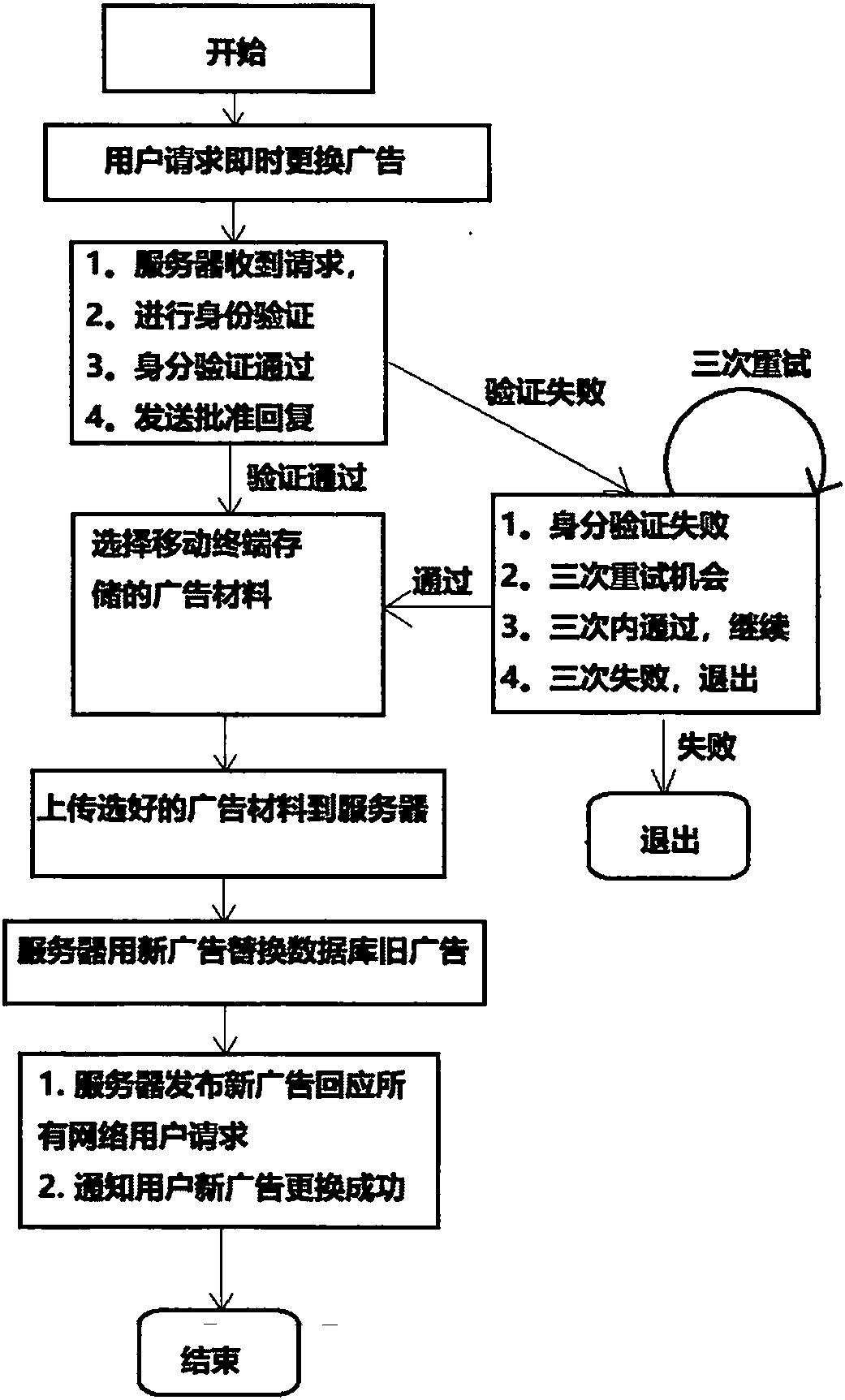

Method for dynamically replacing iconic interface label advertisement of network mapmerchant

PendingCN107993093AShorten the timeEasy to browseGeographical information databasesSpecial data processing applicationsWeb Map ServiceReplacement method

The invention discloses a completely innovative method for replacing interface label advertisement of a network map iconic merchant. The network map merchant can submit an application for replacementwith a merchant iconic interface label advertisement needed by the merchant online; after a network service provider authorizes the application, all new icons submitted by the iconic merchant can be replaced with the new merchant iconic interface label advertisement within the range of all network maps of the APP. All current worldwide network map service providers, such as Google Maps and Baidu Maps, do not have the service, the method is original, and the concept and implementation method of the method for dynamically replacing the network map iconic merchant interface label advertisement bythe mobile terminal merchant are provided completely and systematically for the first time all around the world.

Owner:王勇 +2

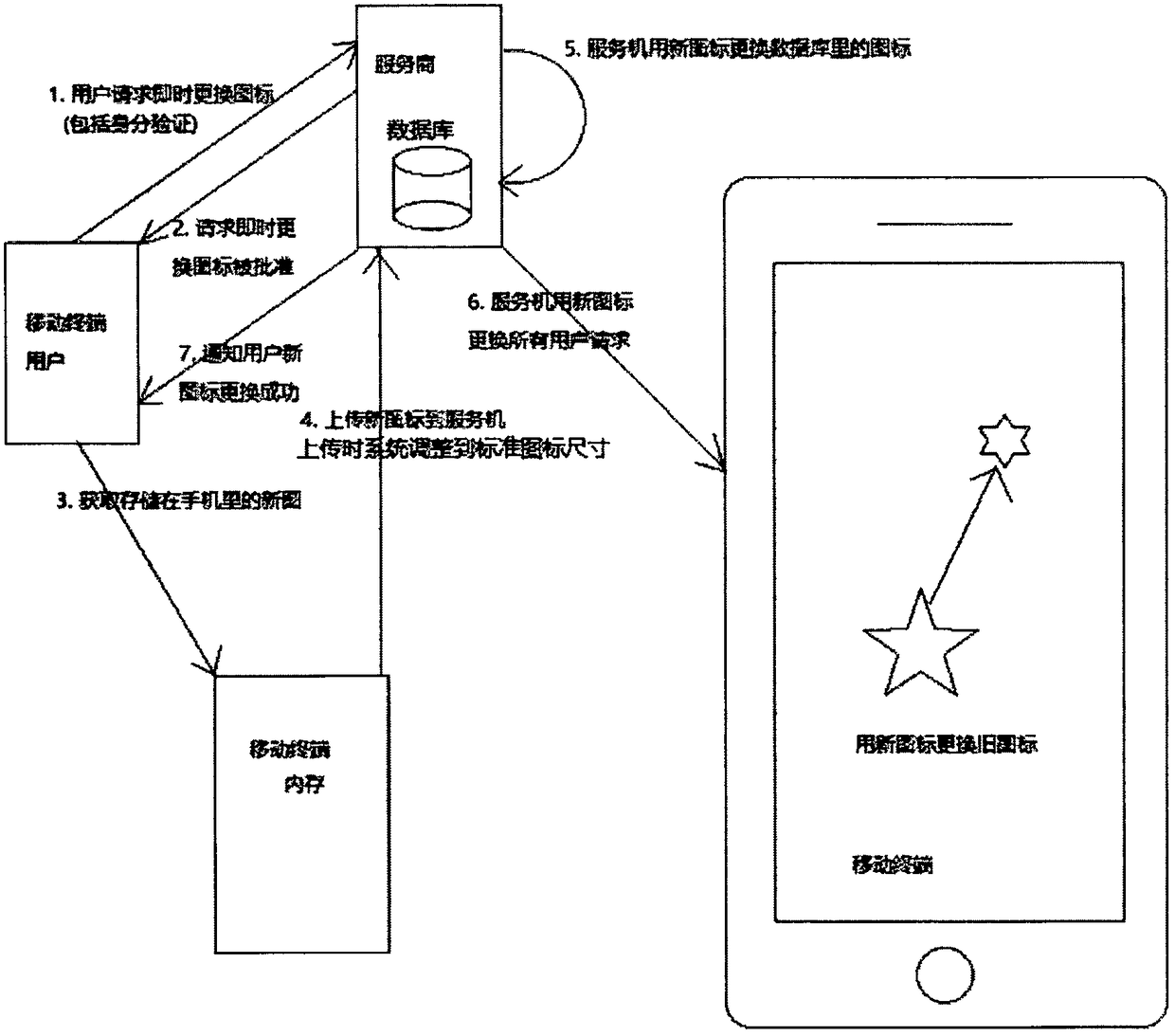

Network map user icon dynamic-replacement method

InactiveCN108090144AAttractiveExtended Icon FunctionsBuying/selling/leasing transactionsGeographical information databasesWeb Map ServiceComputer terminal

The invention discloses a completely innovative network map user icon dynamic-replacement method. A network map user can submit an application of replacement of a favorite icon of the user online, andthe new icon submitted by the user is used for entire replacement in all network map ranges of an APP after acceptance and approval of a network facilitator. All current network map facilitators, such as Google Map and Baidu Map, in the world do not have the service, and the invention of us is original, and completely and systematically provides, for the first time in the world, a concept and theimplementation method of dynamic replacement of the user icon of mobile user terminals.

Owner:王勇 +2

Precured glass fiber cloth impregnation material and preparation method thereof

The invention discloses a precured glass fiber cloth impregnation material. The precured glass fiber cloth impregnation material is characterized by being composed of a glass fiber cloth which is coated with adhesive by adopting a gluing machine and baked by a baking tunnel of the gluing machine, wherein the adhesive is formed by mixing 1000 parts by mass of benzoxazine-maleic amide resin solution, 15-30 parts by mass of linear isophthalic type unsaturated polyester, 0.2-2 parts by mass of an accelerant and 0.1-0.3 part by mass of initiator. A preparation method of the precured glass fiber cloth impregnation material comprises the following steps: preparing a benzoxazine-maleic amide resin solution, preparing adhesive, coating the adhesive on the glass fiber cloth by adopting a gluing machine, baking the glass fiber cloth by virtue of a baking tunnel of the gluing machine, and rolling, thus the precured glass fiber cloth impregnation material is obtained. By adopting the preparation method of the precured glass fiber cloth impregnation material, the storage time of a benzoxazine resin-based precured glass fiber cloth impregnation material can be prolonged, the fragility of a post processing product is reduced, and stratification is reduced; the precured glass fiber cloth impregnation material can be applied to mould pressing, laminating and rolling of an electric insulation or structural composite material.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

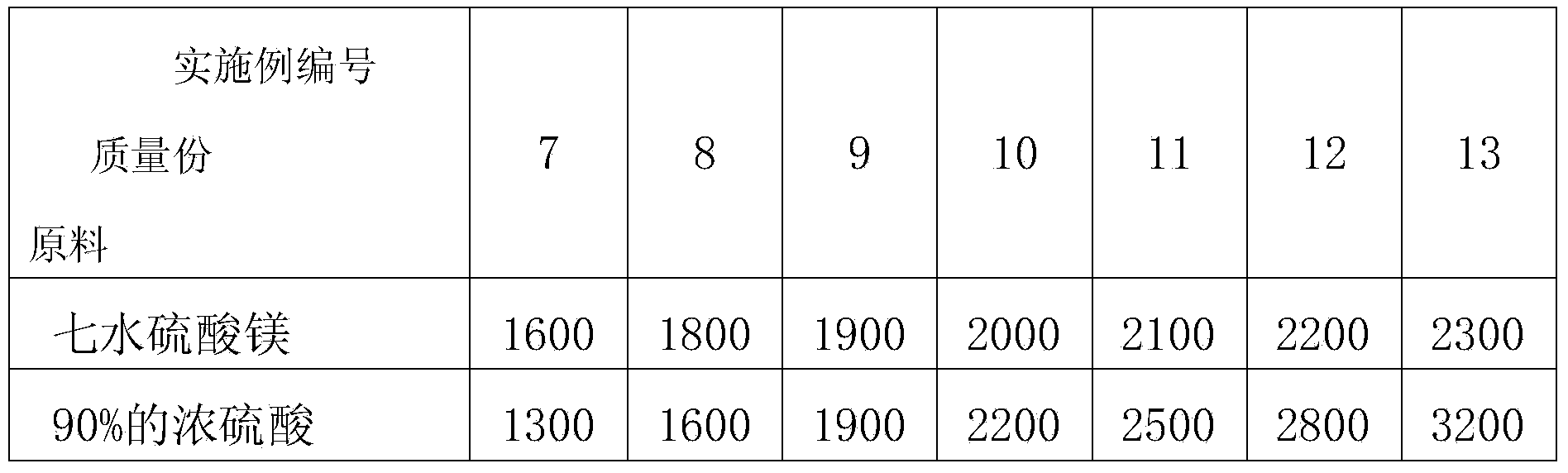

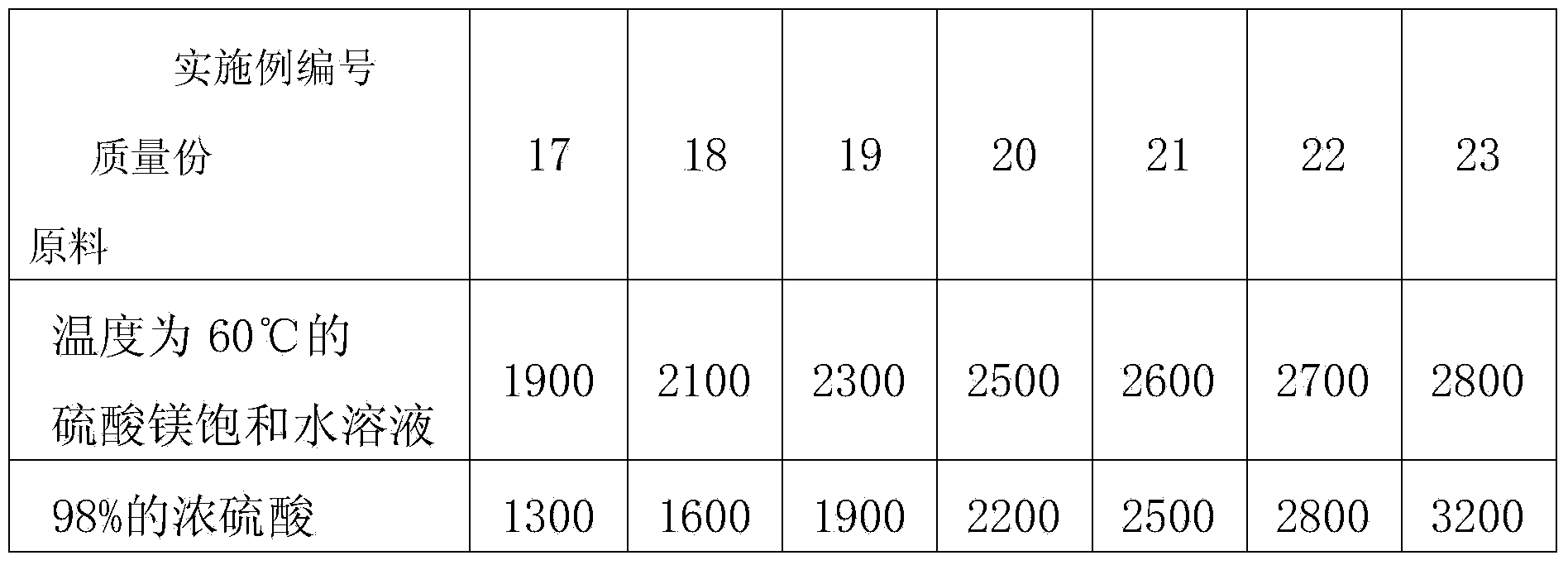

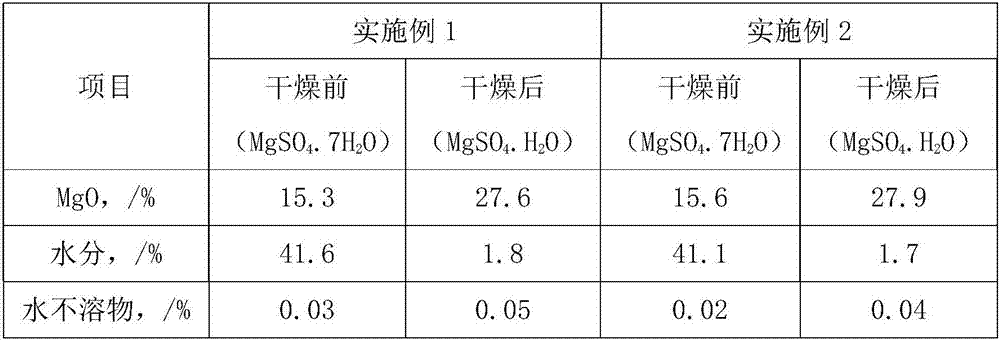

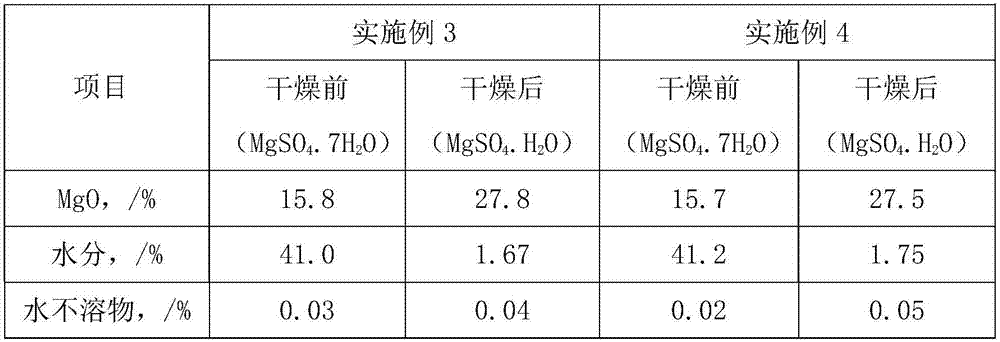

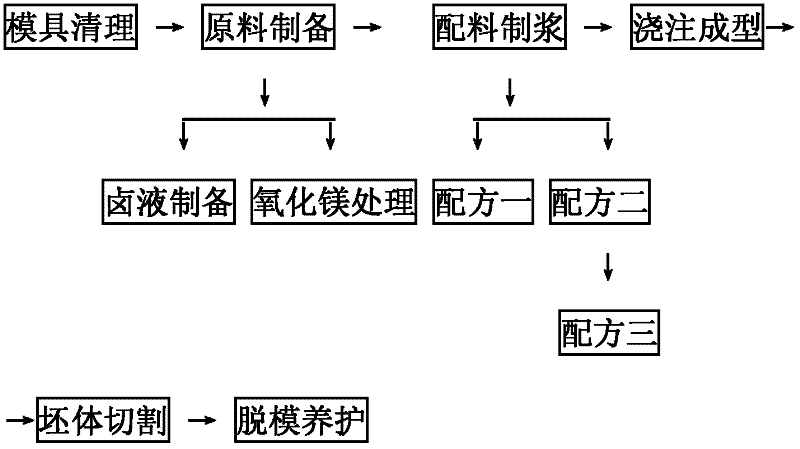

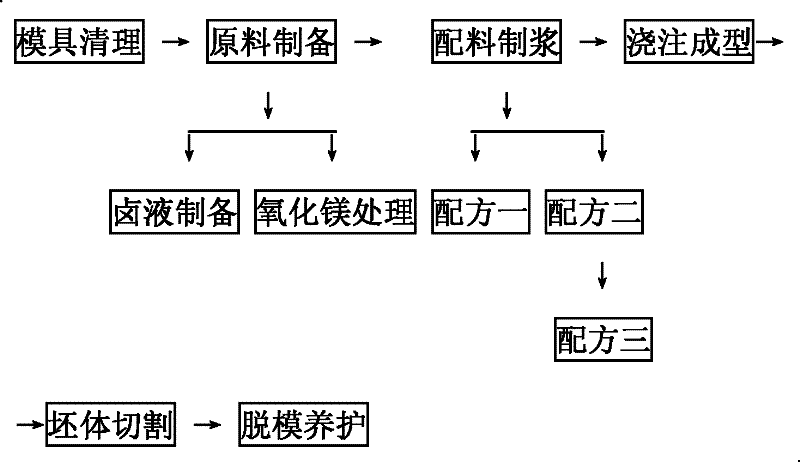

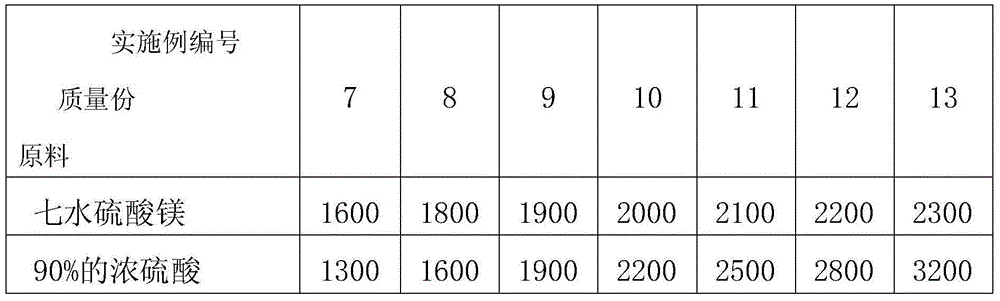

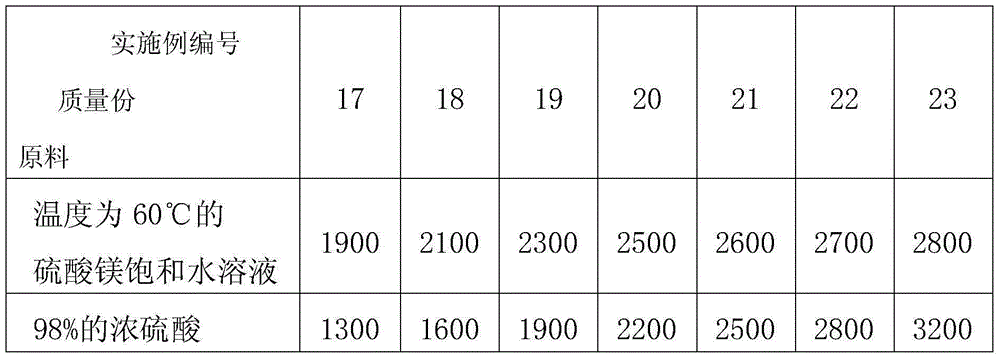

Production method of magnesium sulfate monohydrate

InactiveCN104291367ASimple methodNo emissionsMagnesium sulfatesEnergy consumptionSaturated aqueous solution

The invention discloses a production method of magnesium sulfate monohydrate. The production method of magnesium sulfate monohydrate is characterized by comprising the following steps: adding 1200-3500 parts by mass of 90-98% concentrated sulfuric acid into 1500-2500 parts by mass of magnesium sulfate heptahydrate or 1800-3000 parts by mass of a magnesium sulfate saturated aqueous solution with the temperature of 50-90 DEG C under the condition of stirring, and stirring and reacting for 1-2 hours to obtain a suspension liquid of magnesium sulfate monohydrate; filtering the suspension liquid, washing a filter cake once by using the magnesium sulfate saturated aqueous solution, and then washing once to twice by using water; and drying the washed filter cake for 0.5-1 hour at 120-150 DEG C to prepare magnesium sulfate monohydrate. The production method disclosed by the invention is short in production process, simple in equipment, low in energy consumption and low in cost, is suitable for industrial large-scale production, and is good in commercial effect and strong in practicability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

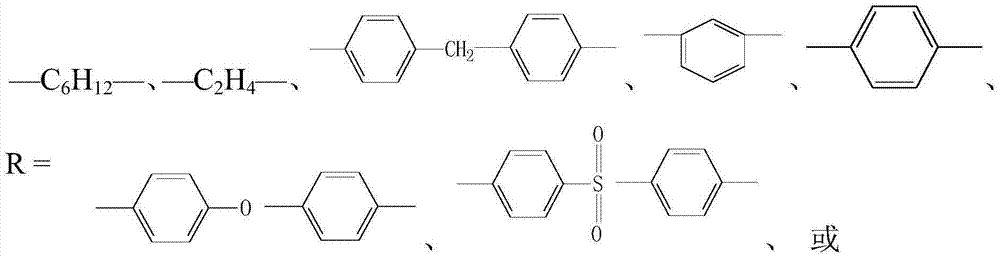

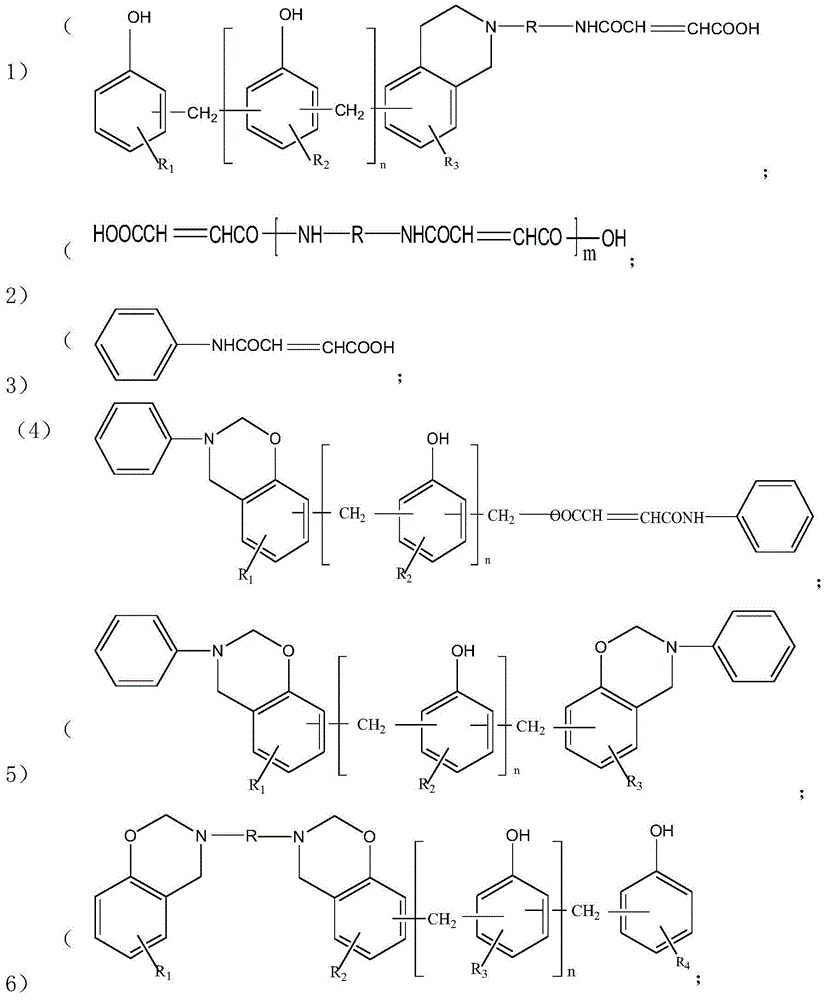

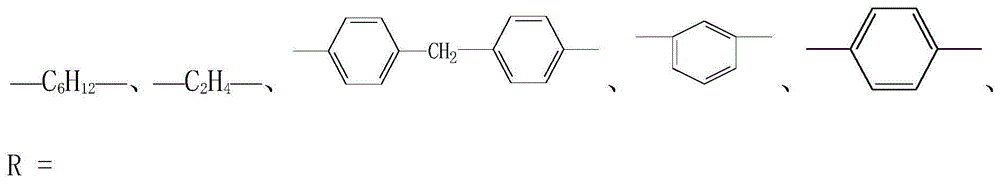

Preparation method and use of resin mixture containing benzoxazine-maleic amide

ActiveCN103497333AImprove brittlenessVery low brittlenessSynthetic resin layered productsRoom temperatureSolvent

The invention discloses a preparation method of a resin mixture containing benzoxazine-maleic amide, which is characterized by comprising the following steps: throwing an amine compound, maleic anhydride and a solvent into a reactor A, stirring and heating up to 70-95 DEG C, reacting for 1-2 h, and cooling to the room temperature to obtain an intermediate solution; throwing the intermediate solution into a reactor B, cooling and maintaining at 0-20 DEG C, adding a 40% formaldehyde aqueous solution, controlling the temperature within 20 DEG C, reacting for 1-2 h, regulating the pH to 6-7, adding a phenolic compound and a solvent, reacting at 70-100 DEG C for 2-5 h, standing to stratify into an organic phase and an aqueous phase, vacuum distilling the organic phase to remove the solvent, and drying the remaining substance to obtain the resin mixture containing benzoxazine-maleic amide. The resin mixture is good in performance and is suitable for manufacturing electrical insulating structural members, coating materials or structural composite materials.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Foaming agent for oilfield, and preparation method thereof

The invention discloses a foaming agent for oilfield. The foaming agent is prepared from the following raw materials in percentage by mass: 10%-20% of dodecyl dimethyl betaine, 5%-15% of lauramidopropyl betaine, 3%-10% of caprylyl / capryl glucoside, 1%-5% of butanediol, and 55%-80% of deionized water, wherein the sum of weight percentages of the components is 100%. The invention further discloses a preparation method of the foaming agent. The foaming agent for oilfield can be used for oil-gas field development operation of oil-gas well drilling, oil-gas well pigging and washing, gas well cracking, gas well drainage and gas recovery and the like, especially for the ultralow-permeability oil-gas area in the north of Shanxi province, the foaming agent has a good foaming effect in stratum water with the mineralization degree of 20*10<4>mg / L and the stratum with the temperature of 130DEG C, and has obvious commercial effect in practical site use.

Owner:陕西延长石油油田化学科技有限责任公司

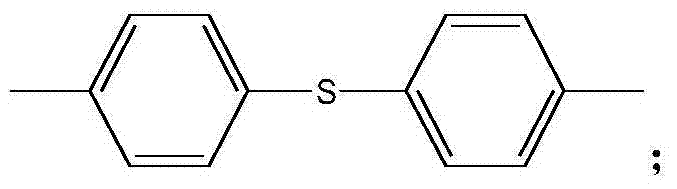

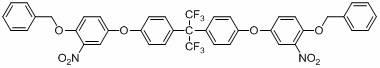

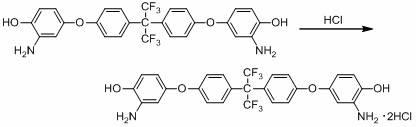

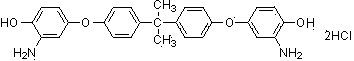

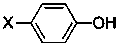

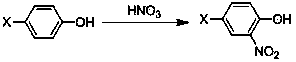

Bisphenol 2 (m-amino p-hydroxy phenyl) ether hydrochloride and preparation method and application thereof

ActiveCN102584610AImprove solubilityEnhance molecular flexibilityOrganic compound preparationAmino-hyroxy compound preparationSolubilityPolyamide

The invention discloses bisphenol 2 (m-amino p-hydroxy phenyl) ether hydrochloride such as 2,2-2(4-(3-amino-4-hydroxy phenoxy)phenyl) propane hydrochloride and a preparation method and an application of the bisphenol 2 (m-amino p-hydroxy phenyl) ether hydrochloride. The preparation method comprises the steps: nitrating p-hydroxy halogen benzene to obtain m-nitro p-hydroxy halogen benzene, protecting hydroxyl by benzyl, coupling the hydroxyl with a bisphenol agent to obtain ether, removing benzyl by means of hydrogenation and reduction and reducing nitryl into amino, and finally using hydrochloric acid to perform salifying to obtain the bisphenol 2 (m-amino p-hydroxy phenyl) ether hydrochloride. The compound provided by the invention is particularly suitable for the preparation of soluble polybenzoxazol, and the prepared polybenzoxazol has the characteristics of high strength and solubility in the common organic solvent, the defects of insolubility and difficulty in processing of the existing polybenzoxazol polymer are overcome, and the bisphenol 2 (m-amino p-hydroxy phenyl) ether hydrochloride can also be used for the preparation of polyamide and polyimide.

Owner:四川东材绝缘技术有限公司

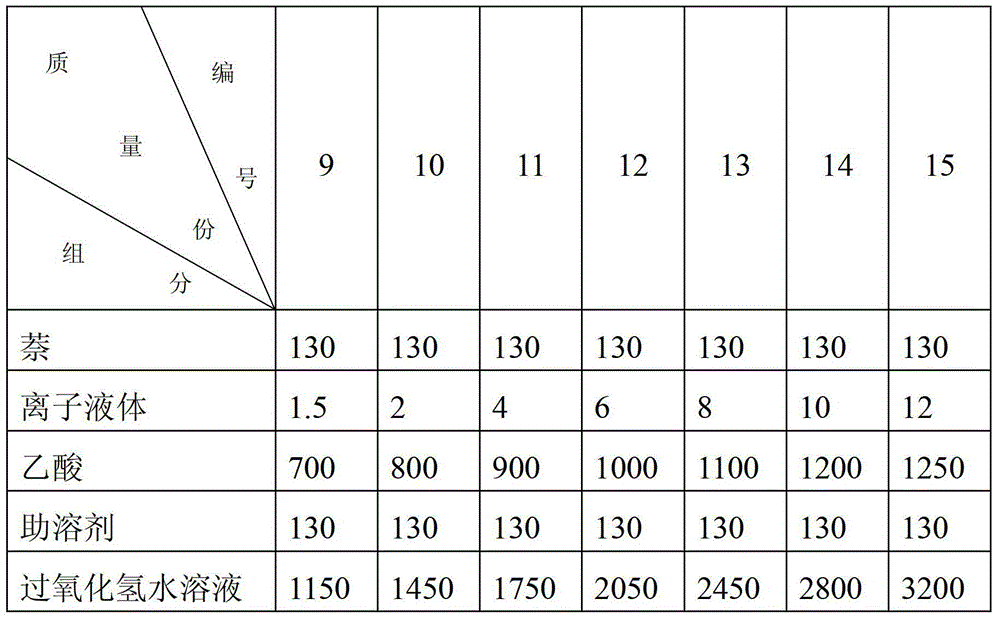

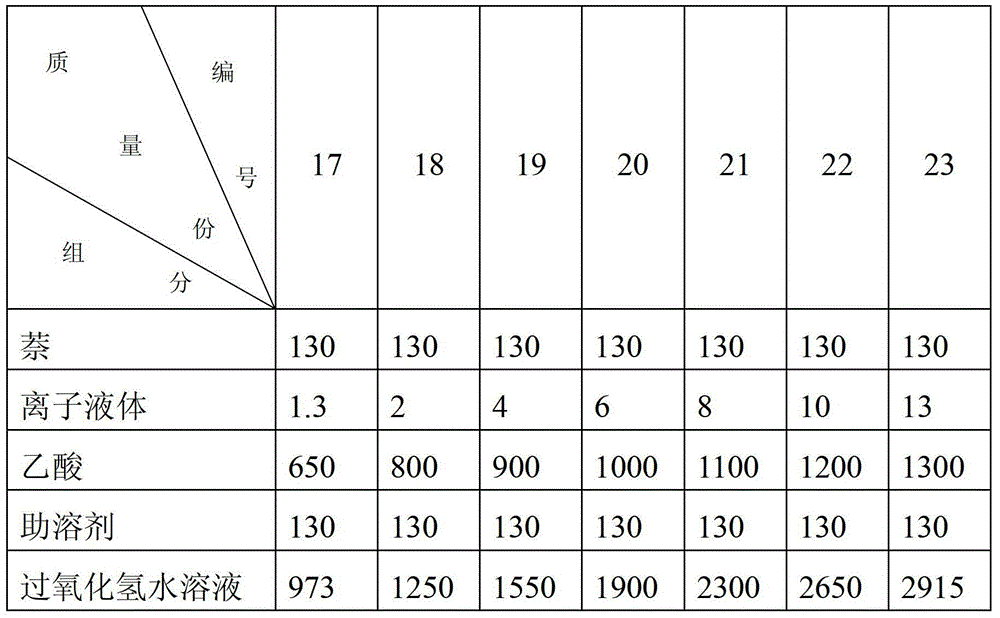

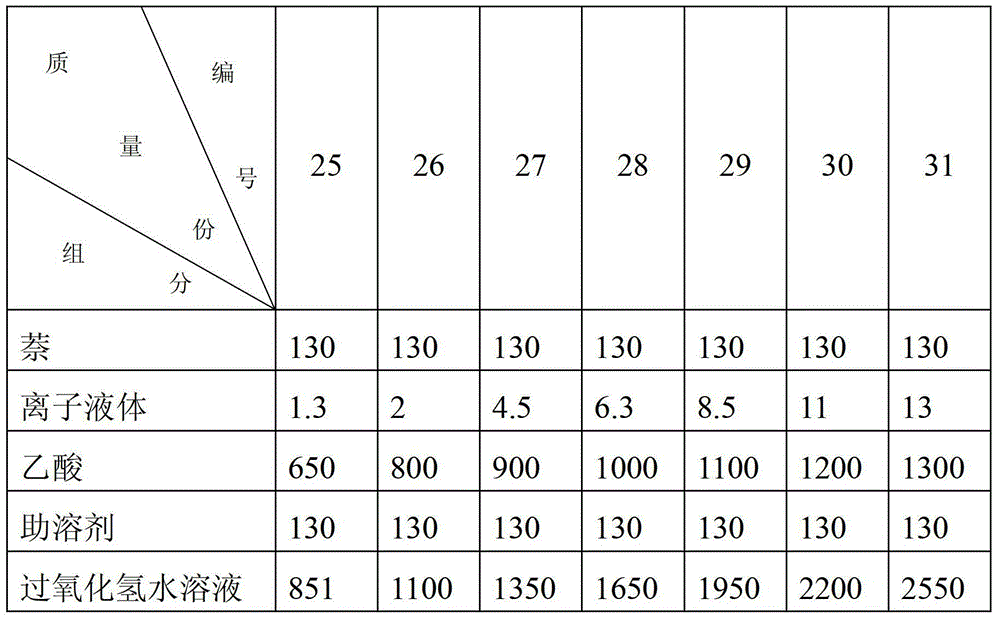

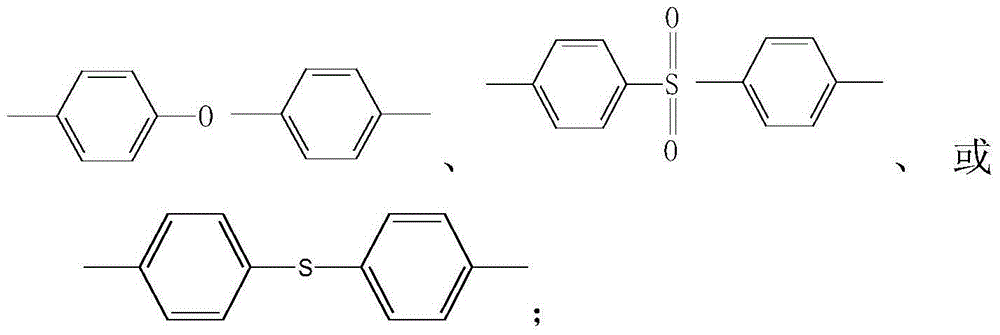

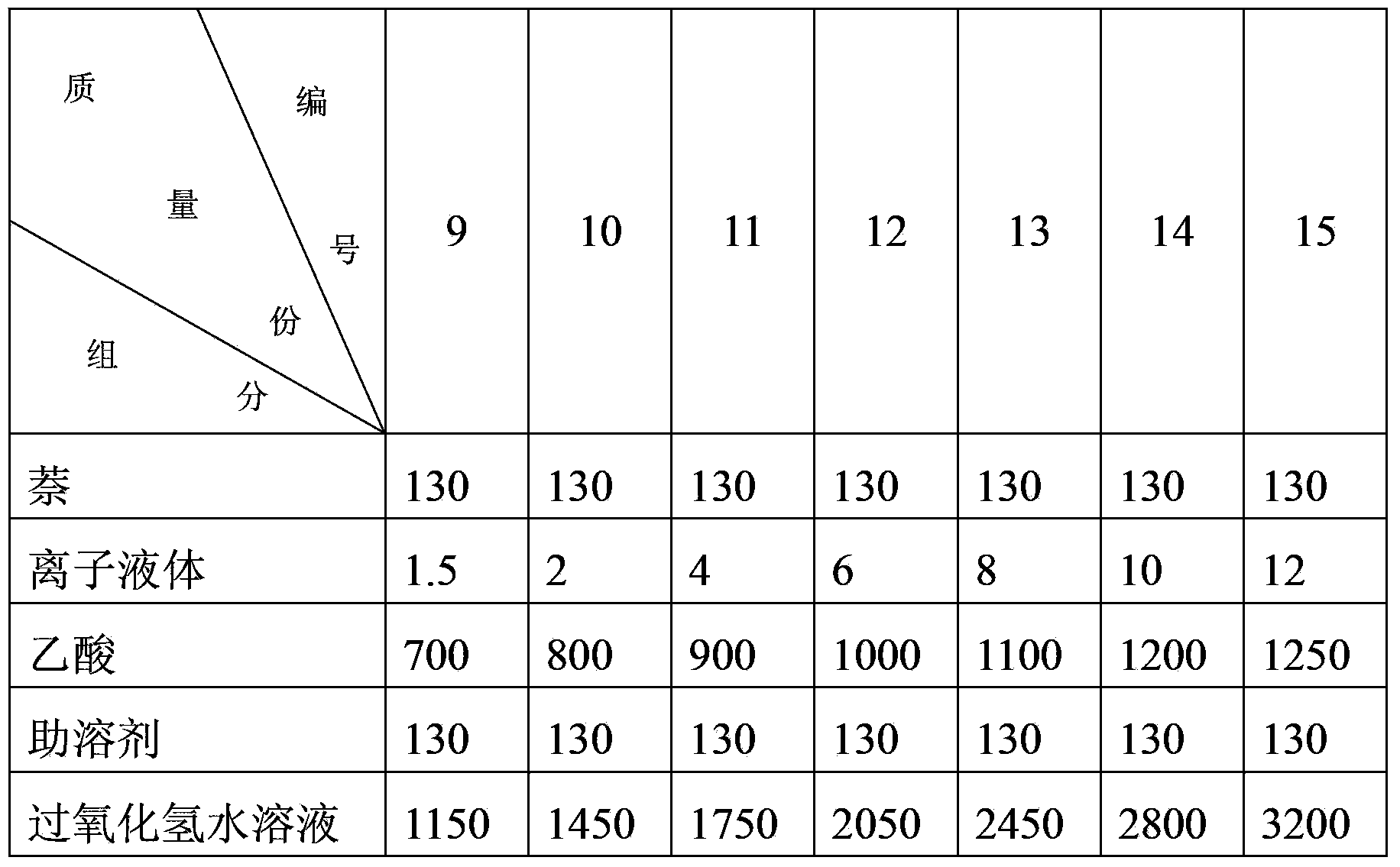

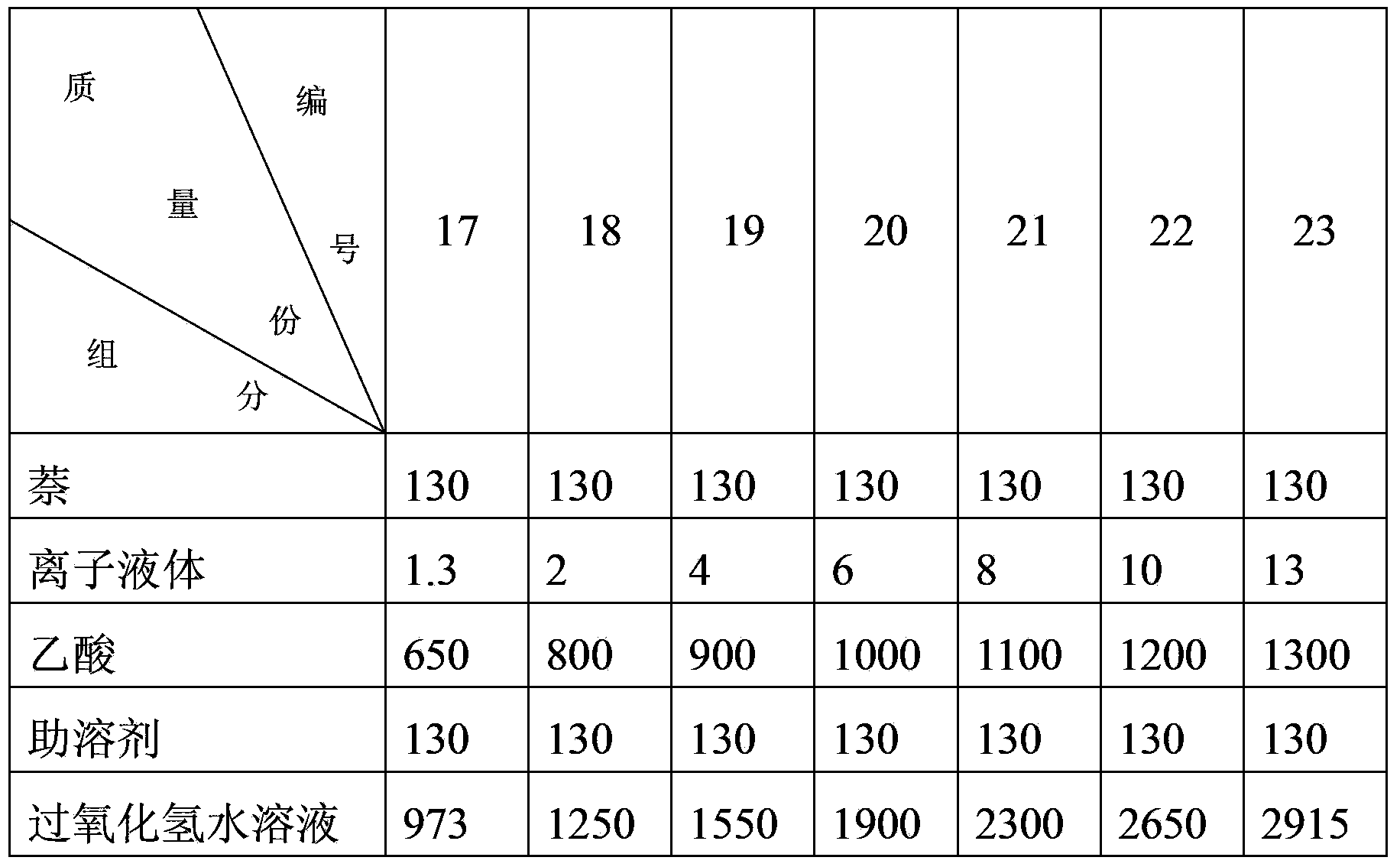

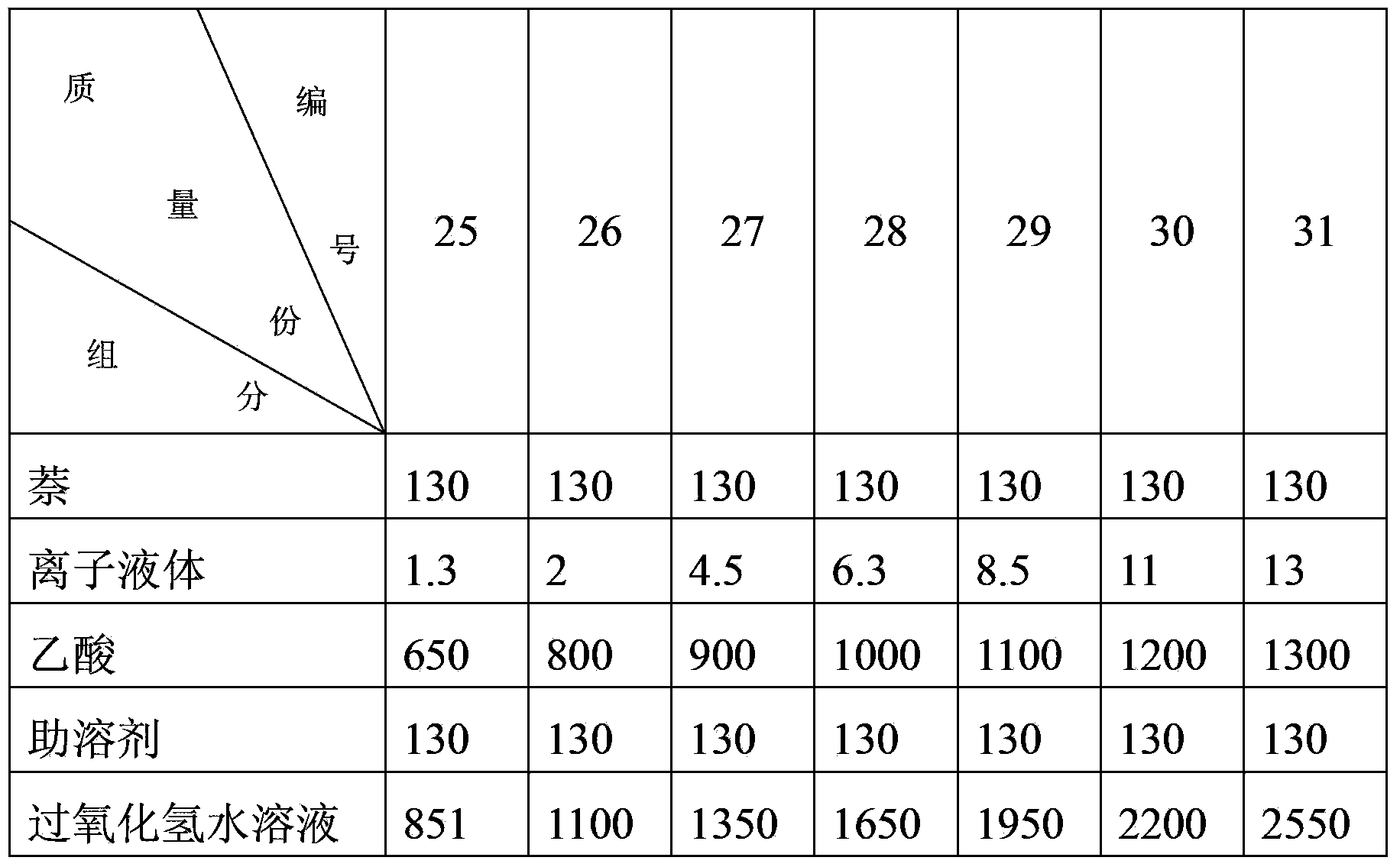

Method for synthesizing 1,4-naphthoquinone through catalyzing ionic liquid

ActiveCN103483175BSolve technical problems with severe pollutionHigh selectivityQuinone preparation by oxidationDistillationSolvent

Owner:四川东材绝缘技术有限公司

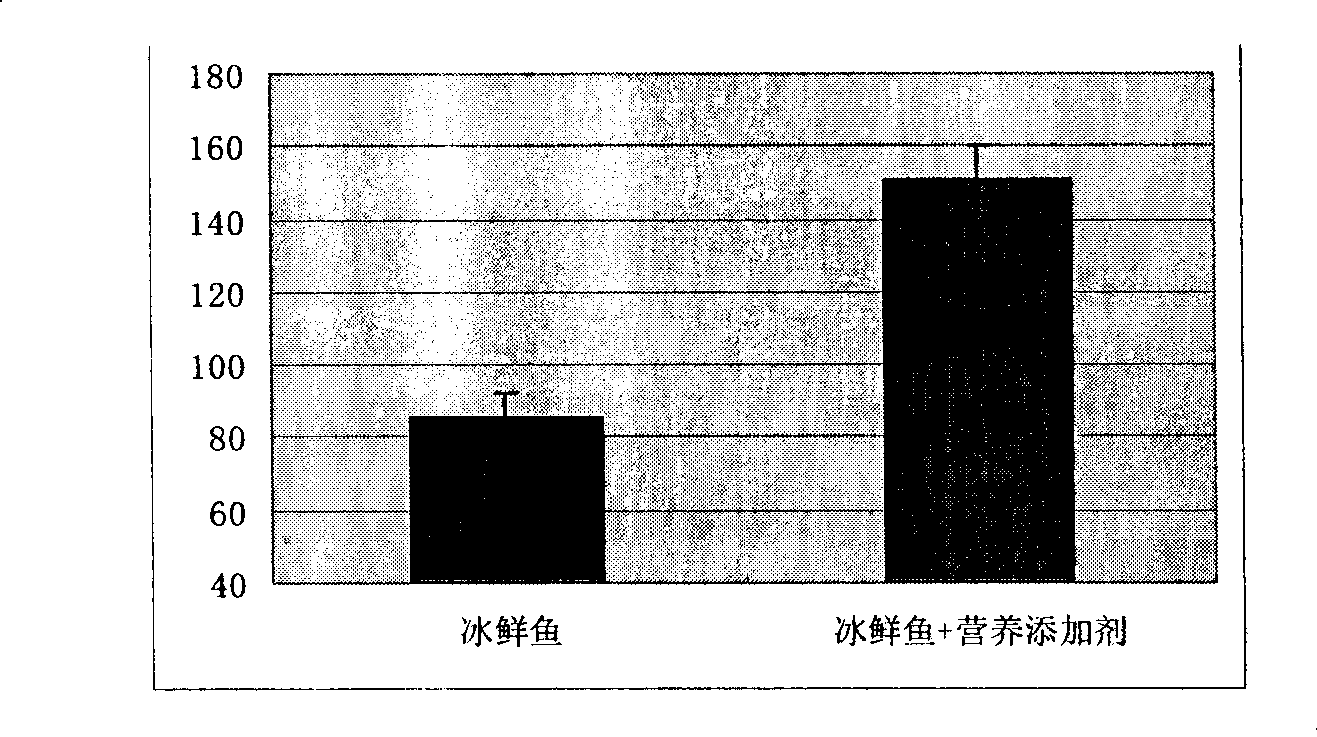

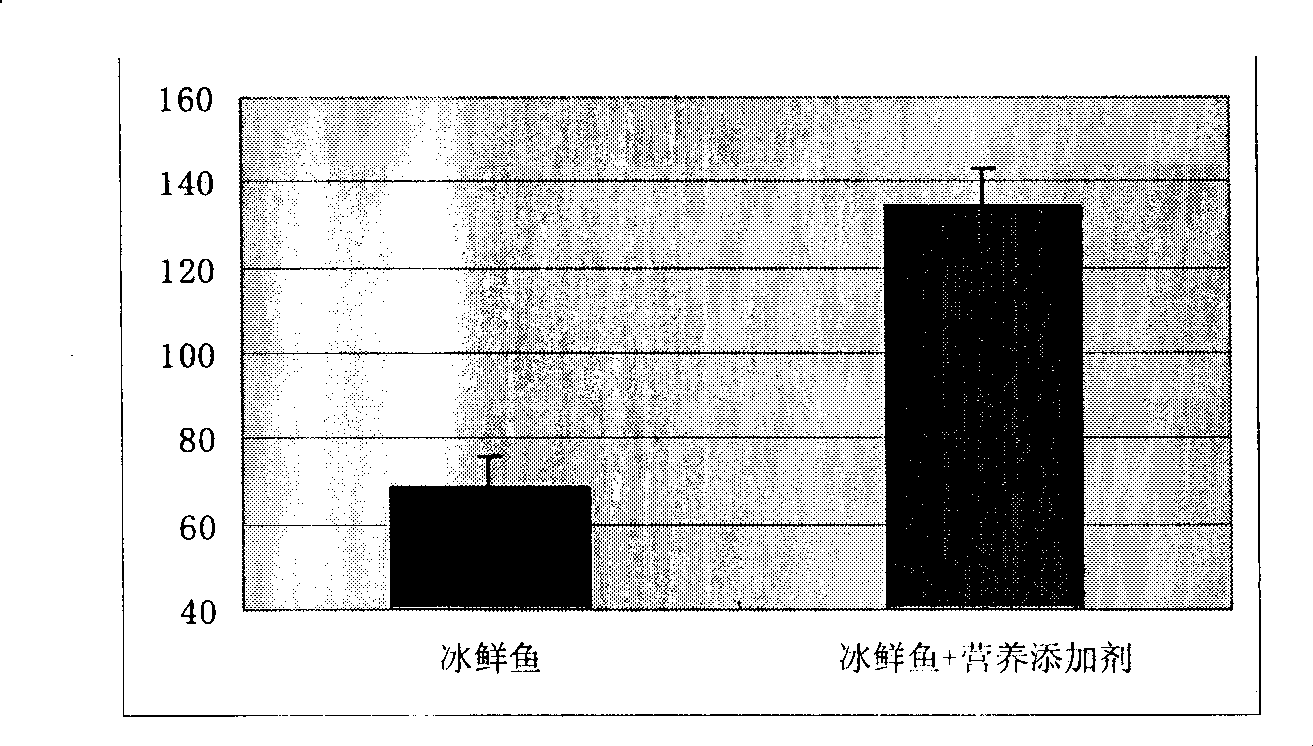

Iced fish nutrient additive

InactiveCN101455273AFood safetyReduce dosageAnimal feeding stuffAccessory food factorsVitamin CPotato starch

An iced fish nutrition additive is characterized by constituting: 30.00% of white fish meal, 25.00% of potato starch, 0.40% of compound enzyme, 20.00% of MCP, 0.50% of vitamin C, 0.40% of carnitine, 0.20% of allicin, 1.00% of Chinese herbal medicine, 12.00% of freshwater fish multivitamin and multiple mineral nutrients, 10.50% of beer yeast. The nutritional additive is easy to add, can be attached to the iced fish effectively, and is not easy to dissolve in water to cause waste; can effectively supplement the shortage of fresh ice, in order to better meet the nutritional requirements of farmed fish; sufficient quantity vitamins and immune-enhancing substances are added, so that the invention effective reduces the use of antibiotics and other drugs to make fish for human consumption to be more safe; security; the invention promotes the rapid growth of farmed fish, and has high breeding survival rate, few use of iced fish, saved the breeding cost, easy tangible business results in the promotion.

Owner:王新霞

A kind of precured glass fiber cloth impregnation material and preparation method thereof

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Method for synthesizing 1,4-naphthoquinone through catalyzing ionic liquid

ActiveCN103483175ASolve technical problems with severe pollutionHigh selectivityQuinone preparation by oxidationDistillationSolvent

The invention discloses a method for synthesizing 1,4-naphthoquinone by catalyzing an ionic liquid. The method is characterized in that 130 mass parts of naphthalene, 1.3-13 mass parts of an ionic liquid, 650 to 1,300 mass parts of acetic acid, 130 mass parts of a booster solvent are added into a reactor, the temperature is increased to 50 to 100 DEG C during stirring, 1,135 to 3,400 mass parts of a hydrogen peroxide water solution with the mass concentration of 30 percent is completely dripped within 1.5 to 2.5 hours, after dripping, heat-insulating reaction lasts for 2 to 5 hours, then filtering is performed, insoluble precipitates are eliminated, a filter liquor is extracted by a resolvent cyclohexane, organic phases are taken, after water washing and drying, reduced pressure distillation is performed, and remnants are the prepared 1,4-naphthoquinone. According to the invention, the method provided by the invention has the characteristics of environment friendless, simplicity and convenience in operation, fast reaction speed and the like, the product cost is low, the commercial effect is excellent, and the practicability is strong.

Owner:四川东材绝缘技术有限公司

Preparation method of magnesium sulfate monohydrate

InactiveCN107162028ANo impact on qualityImprove surface hydrophobicityEnergy inputMagnesium sulfatesThermal efficiencyMaterials science

The invention relates to a preparation method of magnesium sulfate monohydrate and particularly relates to a method which is used for preparing magnesium sulfate monohydrate from magnesium sulfate heptahydrate and has the effect that effective resources are reasonably utilized. According to the preparation method, exhaust gas produced in a sintering or pelletizing procedure in an iron and steel plant is used as a drying medium for drying magnesium sulfate heptahydrate so as to obtain magnesium sulfate monohydrate. The method has the characteristics that the waste heat of exhaust gas is adequately utilized, the steam is not consumed in a drying process, and the energy saving and consumption reducing effects are good; an indirect heat exchange link is reduced, the heat efficiency is high, and the equipment investment is saved; and the cost is lowered by 30%-50%, and the commercial effect is good.

Owner:江苏联慧资源环境科技有限公司

Bisphenol 2 (m-amino p-hydroxy phenyl) ether hydrochloride and preparation method and application thereof

ActiveCN102584610BImprove solubilityEnhance molecular flexibilityOrganic compound preparationAmino-hyroxy compound preparationSolubilityPolyamide

The invention discloses bisphenol 2 (m-amino p-hydroxy phenyl) ether hydrochloride such as 2,2-2(4-(3-amino-4-hydroxy phenoxy)phenyl) propane hydrochloride and a preparation method and an application of the bisphenol 2 (m-amino p-hydroxy phenyl) ether hydrochloride. The preparation method comprises the steps: nitrating p-hydroxy halogen benzene to obtain m-nitro p-hydroxy halogen benzene, protecting hydroxyl by benzyl, coupling the hydroxyl with a bisphenol agent to obtain ether, removing benzyl by means of hydrogenation and reduction and reducing nitryl into amino, and finally using hydrochloric acid to perform salifying to obtain the bisphenol 2 (m-amino p-hydroxy phenyl) ether hydrochloride. The compound provided by the invention is particularly suitable for the preparation of soluble polybenzoxazol, and the prepared polybenzoxazol has the characteristics of high strength and solubility in the common organic solvent, the defects of insolubility and difficulty in processing of the existing polybenzoxazol polymer are overcome, and the bisphenol 2 (m-amino p-hydroxy phenyl) ether hydrochloride can also be used for the preparation of polyamide and polyimide.

Owner:四川东材绝缘技术有限公司

Method for dynamic replacement of label advertisements on network map business icon interface

InactiveCN107993093A9Good business effectEasy to browseGeographical information databasesMarketingWeb Map ServiceNetwork service

Owner:王勇 +2

A kind of production method of magnesium sulfate monohydrate

InactiveCN104291367BSimple methodNo emissionsMagnesium sulfatesSaturated aqueous solutionMagnesium sulphate heptahydrate

Owner:SOUTHWEAT UNIV OF SCI & TECH

Skin cleaning nutrient solution containing mongolian snakegourd and red ginseng

InactiveCN1302763CAnti agingPrevention and CrackingCosmetic preparationsToilet preparationsKorean ginsengFoaming agent

Skin cleaning nutrient solution containing mongolian snakegourd and red ginsengwhich comprises sub-structure liquid, enhancing liquid, glycerol, blowing agent and perfume compound. The sub-structure liquid is a mixed liquid prepared from Mongolian snakegourd material and carboxycellulose. The process comprises grinding the pulp, filtering, boiling for 20 minutes, then filtering to obtain the enhancing liquid.

Owner:吕改英

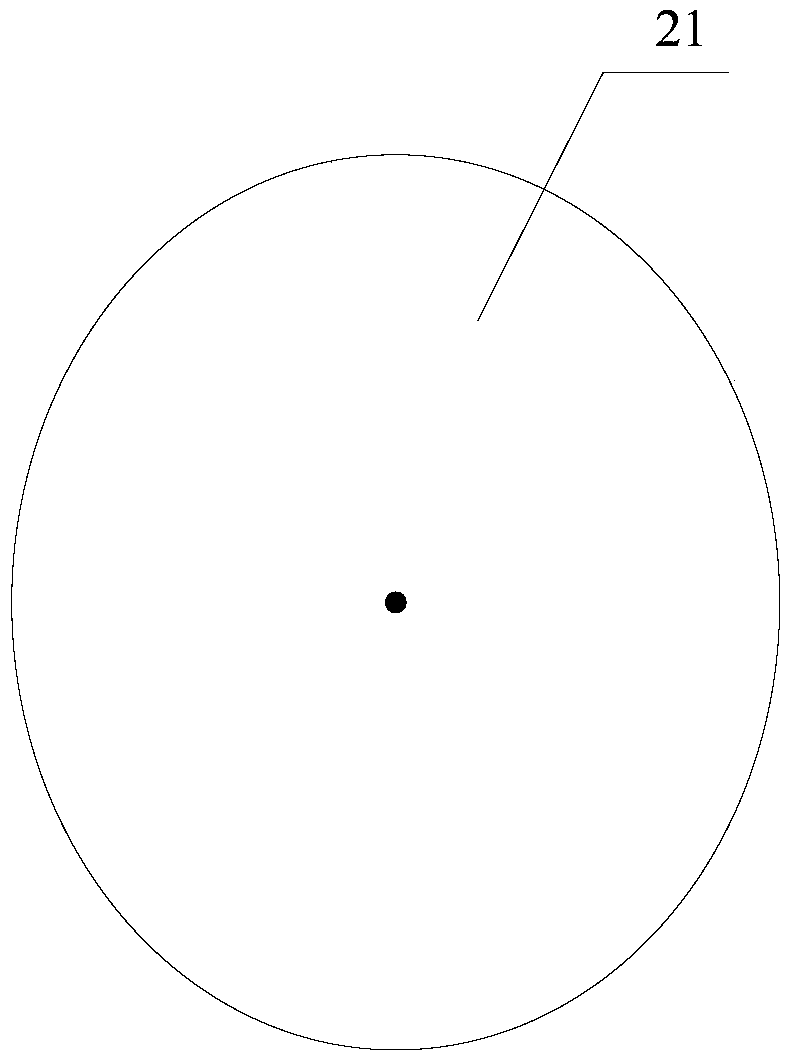

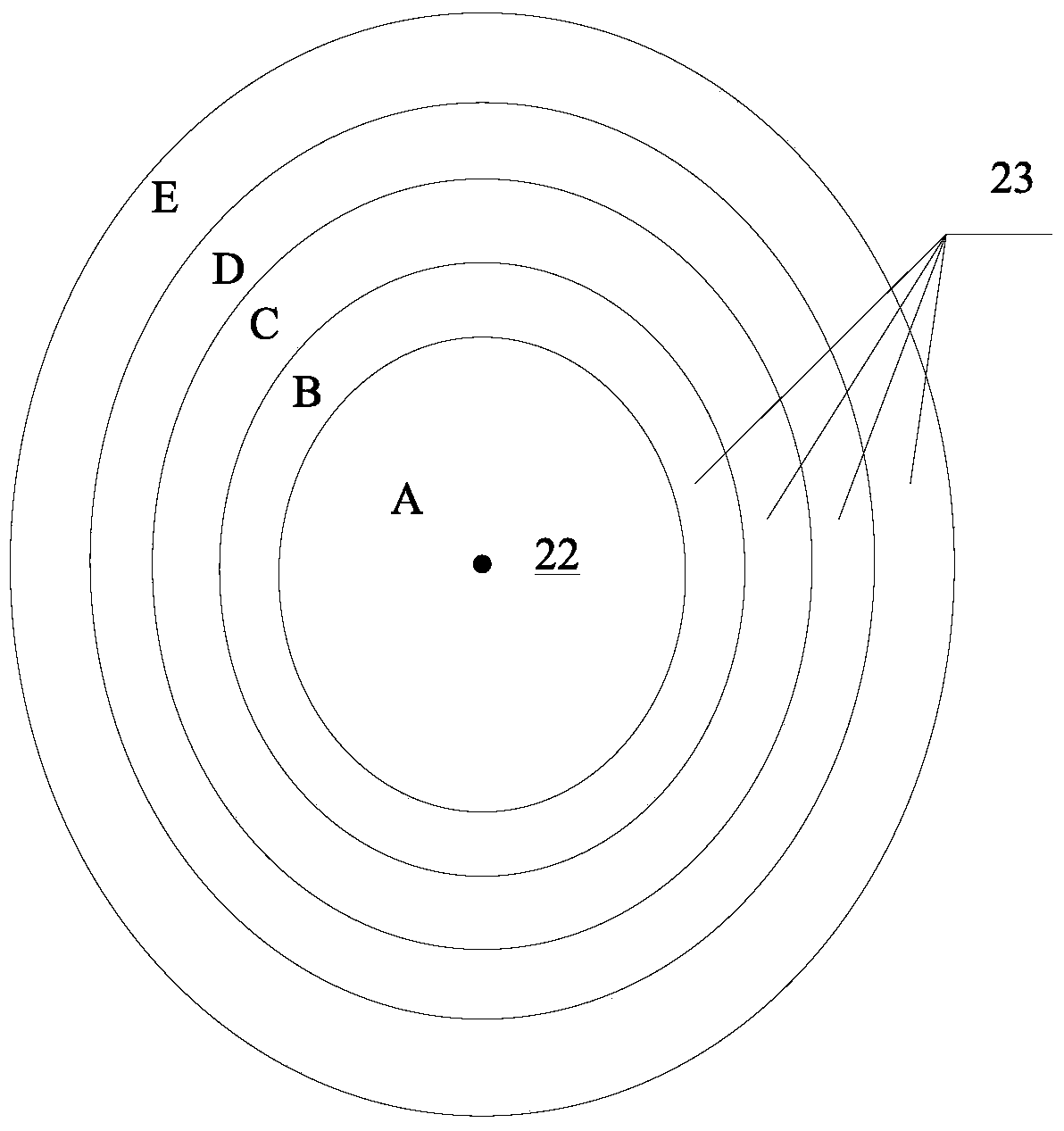

A method and device for pushing information

The embodiment of the present invention provides an information push method and device. The information push method comprises the steps of obtaining the geographical location information of a user terminal; when the user terminal is determined to enter a preset area according to the geographical location information of the user terminal, obtaining the mobile data of the user terminal in the preset area, wherein the mobile data at least comprises one of the distance with an appointed place, the stay time and a mobile distance; according to a preset information push strategy, searching the to-be-pushed information matching the mobile data of the user terminal; pushing the to-be-pushed information to the user terminal. According to the embodiment of the application, the information accurate push is realized, the accuracy of an information push object is improved, thereby achieving the precision marketing purpose of a merchant to a user, and realizing a better business effect. Moreover, the method avoids the information batch sending in a conventional mode and aiming at a lot of users, the transmission of the information amount between the terminals is reduced effectively, and the network resources are saved.

Owner:ADVANCED NEW TECH CO LTD

Preparation method and application of benzoxazine-maleamide resin mixture

ActiveCN103497333BImprove brittlenessVery low brittlenessSynthetic resin layered productsRoom temperatureSolvent

The invention discloses a preparation method of a resin mixture containing benzoxazine-maleic amide, which is characterized by comprising the following steps: throwing an amine compound, maleic anhydride and a solvent into a reactor A, stirring and heating up to 70-95 DEG C, reacting for 1-2 h, and cooling to the room temperature to obtain an intermediate solution; throwing the intermediate solution into a reactor B, cooling and maintaining at 0-20 DEG C, adding a 40% formaldehyde aqueous solution, controlling the temperature within 20 DEG C, reacting for 1-2 h, regulating the pH to 6-7, adding a phenolic compound and a solvent, reacting at 70-100 DEG C for 2-5 h, standing to stratify into an organic phase and an aqueous phase, vacuum distilling the organic phase to remove the solvent, and drying the remaining substance to obtain the resin mixture containing benzoxazine-maleic amide. The resin mixture is good in performance and is suitable for manufacturing electrical insulating structural members, coating materials or structural composite materials.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Foaming agent for oil field and preparation method thereof

The invention discloses a foaming agent for oilfield. The foaming agent is prepared from the following raw materials in percentage by mass: 10%-20% of dodecyl dimethyl betaine, 5%-15% of lauramidopropyl betaine, 3%-10% of caprylyl / capryl glucoside, 1%-5% of butanediol, and 55%-80% of deionized water, wherein the sum of weight percentages of the components is 100%. The invention further discloses a preparation method of the foaming agent. The foaming agent for oilfield can be used for oil-gas field development operation of oil-gas well drilling, oil-gas well pigging and washing, gas well cracking, gas well drainage and gas recovery and the like, especially for the ultralow-permeability oil-gas area in the north of Shanxi province, the foaming agent has a good foaming effect in stratum water with the mineralization degree of 20*10<4>mg / L and the stratum with the temperature of 130DEG C, and has obvious commercial effect in practical site use.

Owner:陕西延长石油油田化学科技有限责任公司

A method for implementing online game operation based on cloud computing

The invention provides a method for achieving online game operation based on cloud computing. The method comprises the following steps: a built-in client of a browser is started on a user terminal to build a request for WEB of a cloud service system to request a list of currently opened zones, and the list is shown for a user; speed measurement is conducted on a selected zone, and temporary identity of the current user is requested; when a speed measurement result meets the requirements, the built-in client carries the speed measurement result to request for the start of a server of a currently available game to the WEB, game image and sound and other information are sent to the built-in client, the built-in client loads the game interface sound and shows the game interface sound for the user, and the user starts the game operation; when the game is played to a pre-set level, a game application program conveys a game-off message to the WEB; a dialog box is popped up to prompt the user to download a game client, and the built-in client of the browser is disconnected with the server at the moment. Through the adoption of the method, the user can be guaranteed to smoothly enter a free-to-try game, so that the user can enter the game once.

Owner:北京沁海科技有限公司

Method for preventing swinging of beam hanging and steel plate during starting and braking of electromagnetic beam hanging crane

A method for preventing the swinging of pylon and steel plate when a pylon-type electromagnetic hoister is started or stopped features that two steel cables used between the bogie and hook of lifting unit are respectively wound on pulleys to a dual-reverse-splayed system to effectively provent said swinging.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

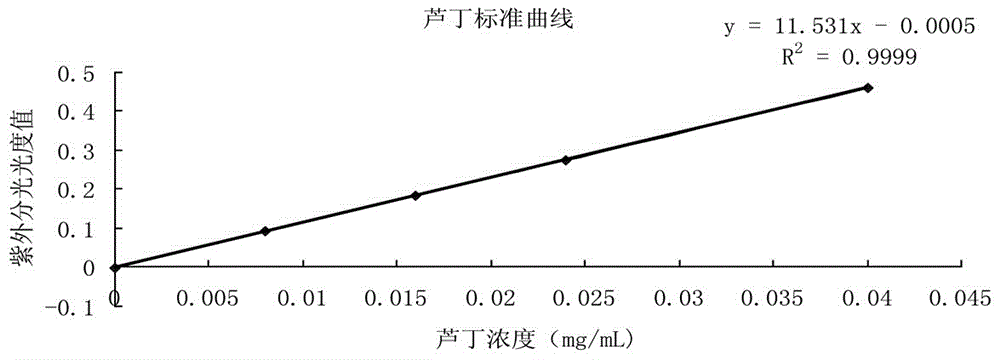

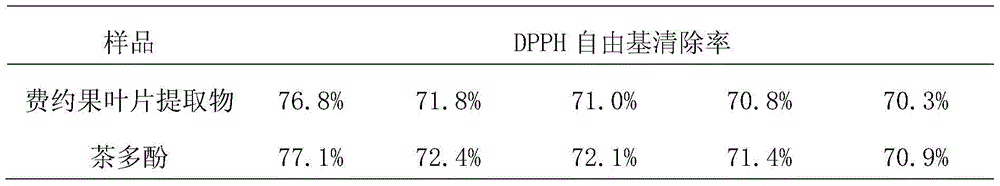

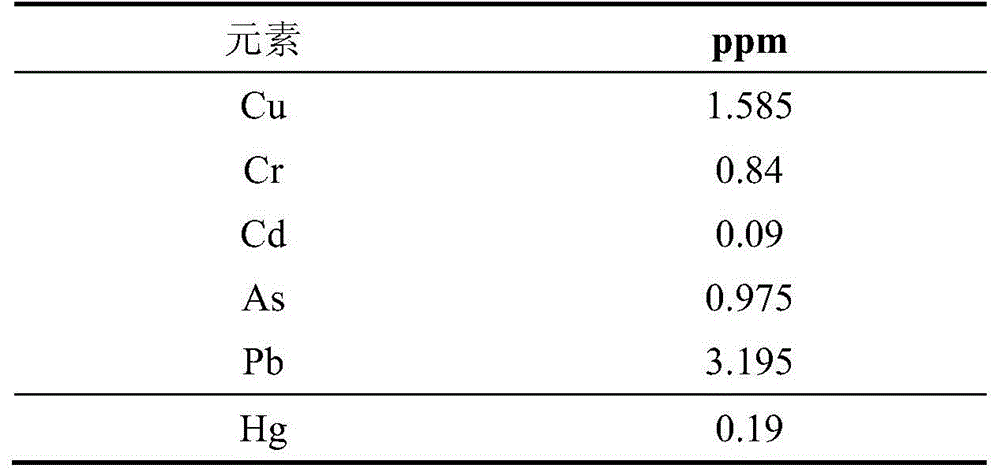

A kind of preparation method of feijoa leaf extract

InactiveCN104306451BReduce lossesBest extraction processAntinoxious agentsFood ingredient as flavour affecting agentBiotechnologyDistillation method

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com