Method for preventing swinging of beam hanging and steel plate during starting and braking of electromagnetic beam hanging crane

A technology of electromagnetic hanging beams and cranes, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of increasing the calculation load of the hoisting mechanism, high processing costs of rigid guide cylinders, and heavy weight of rigid sleeves, etc., to achieve reduction The effect of plant cost, reduction of power and weight of steel structure, reduction of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

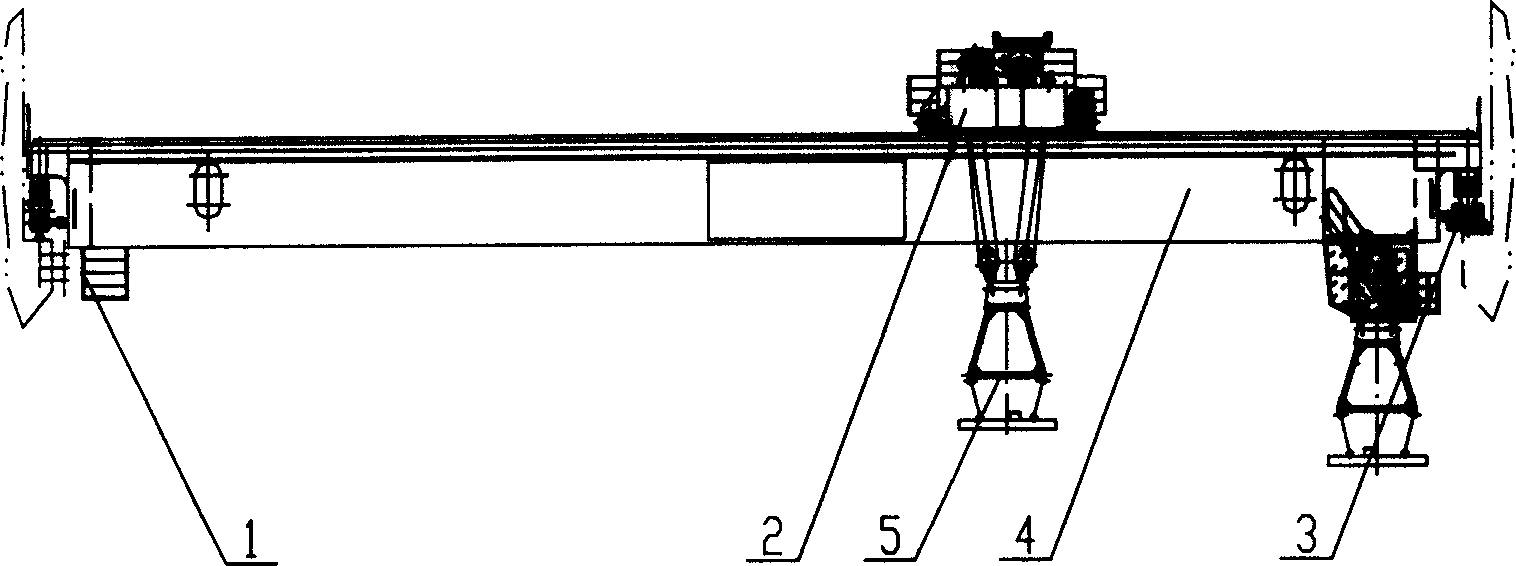

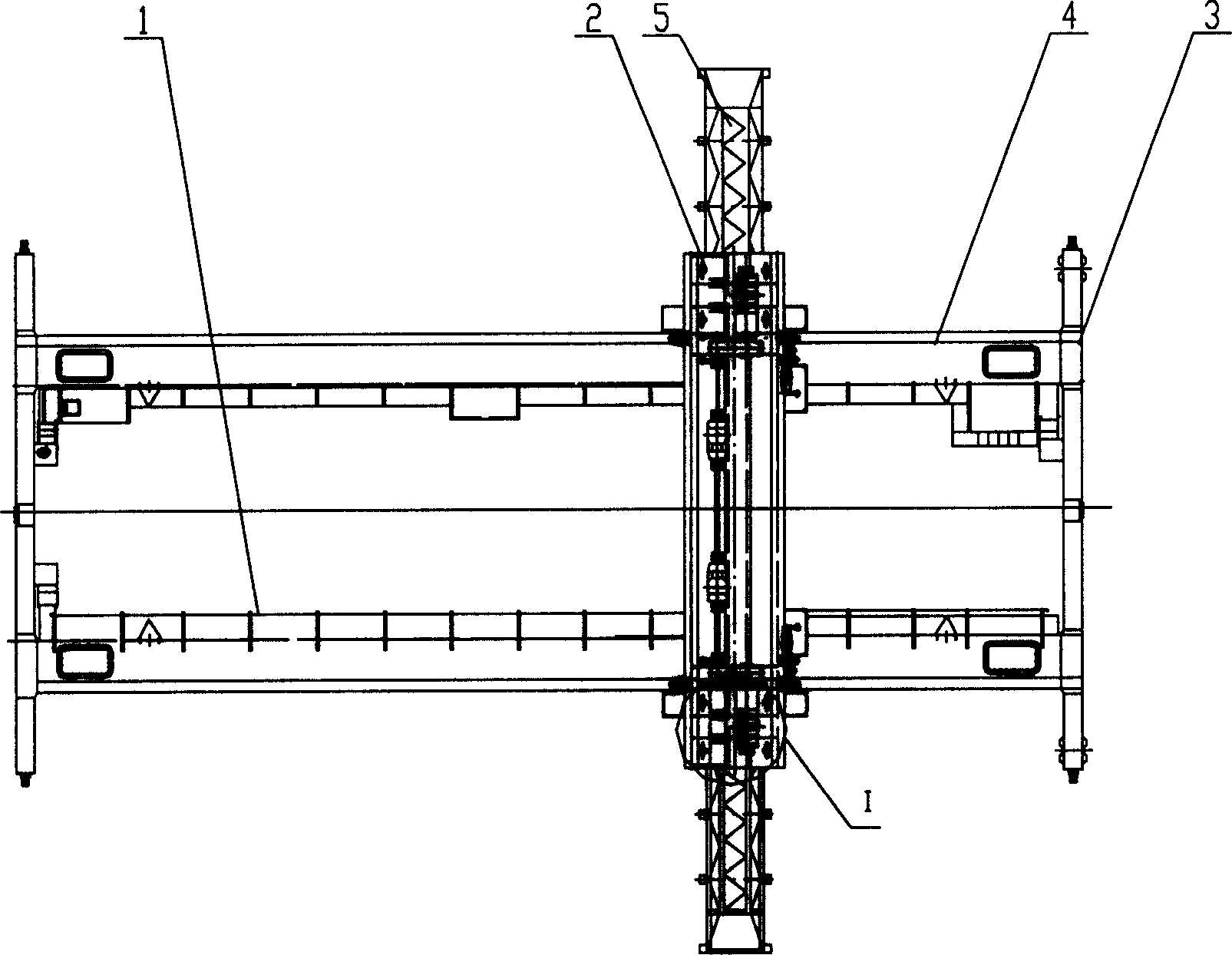

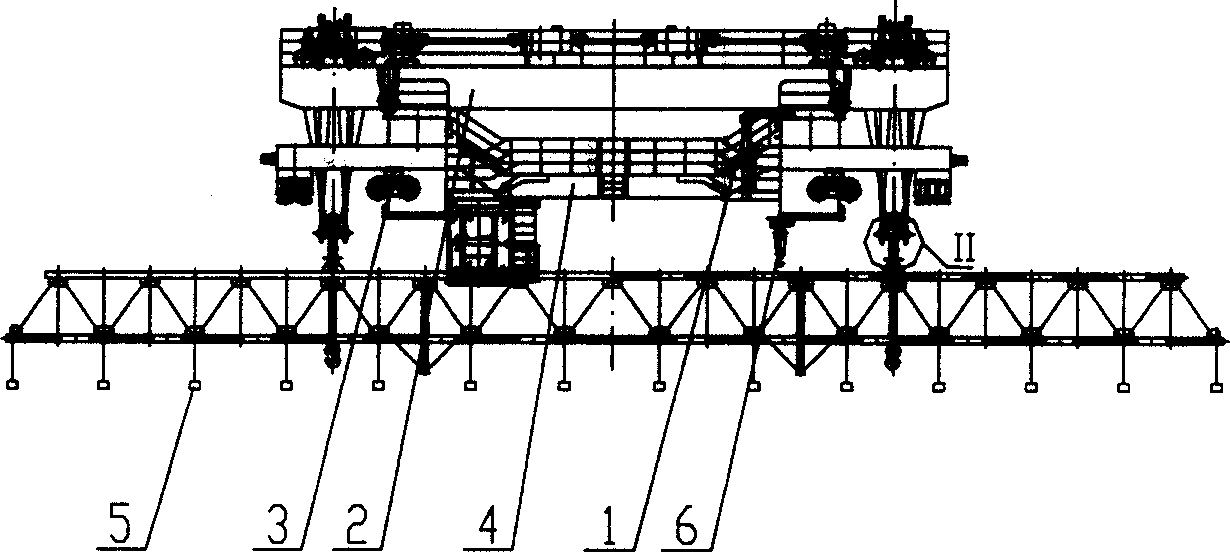

[0014] Figure 1 ~ Figure 3 Shown is an example of the application of the anti-sway winding system of double "inverted splayed" wire ropes formed by the method of the present invention to the hoisting mechanism of an electromagnetic hanging beam crane. This electromagnetic hanging beam crane is composed of six major parts: electrical equipment 1, trolley 2, cart operating mechanism 3, bridge frame 4, truss-type hanging beam 5, and electric hoist 6. There is a set of hoisting mechanisms on both sides of the trolley, and each set of hoisting mechanisms contains a double "inverted character" shaped wire rope anti-swing winding system. Figure 4 and Figure 5 The arrangement forms of the components of the wire rope anti-sway winding system on the trolley and the hook are shown respectively. Depend on Figure 6 It can be seen that a set of hoisting mechanism contains two wire ropes to form a structure of four ropes, from Figure 6 It can be seen that the two strands of steel wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com