Method for producing high-quality potassium chloride

A production method and technology of potassium chloride, applied in the production of potassium chloride, multi-effect vacuum evaporation to produce high-quality potassium chloride, can solve the problems of waste of potassium resources, large emissions, increased pressure on environmental protection, etc., and achieve energy saving , achieve zero emissions and reduce steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

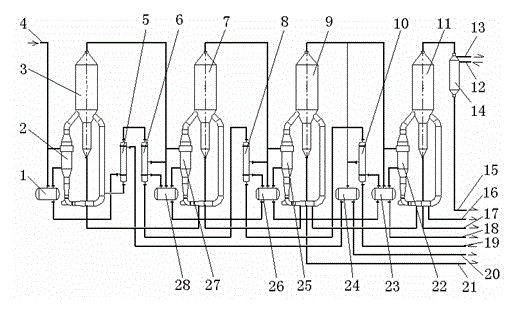

[0024] A. The leaching solution of potassium-containing sintering soot ash (potassium chloride content is 251g / l, sodium chloride content is 55g / l) is sent into the first-stage preheater 10 through the delivery pipe 19, and evaporated with three effects The secondary steam produced by the tank 9 and the flash steam produced by the flash barrel 24 heat the leach solution in the primary preheater 10 to 50°C, send it to the secondary preheater 8, and use the second effect evaporation tank 7 to generate After the secondary steam in the secondary preheater 8 is heated to 70°C, it is sent to the tertiary preheater 6, and the secondary steam generated by the first-effect evaporator 3 is used to heat After the extract solution is heated to 95°C, it is sent to the fourth-stage preheater 5, and the condensate in the first-effect condensate bucket 1 is used to heat the extract solution in the fourth-stage preheater 5 to 110°C and sent to the first-effect evaporation In the tank heating c...

Embodiment 2

[0030] A. The leaching solution of potassium-containing sintering soot ash (potassium chloride content is 200g / l, sodium chloride content is 35g / l) is sent into the primary preheater 10 through the delivery pipe 19, and is evaporated by three effects The secondary steam produced by the tank 9 and the flash steam produced by the flash barrel 24 heat the leachate in the primary preheater 10 to 60°C, send it to the secondary preheater 8, and use the second effect evaporation tank 7 to generate After the secondary steam in the secondary preheater 8 is heated to 85°C, it is sent to the tertiary preheater 6, and the secondary steam generated by the first-effect evaporator 3 is used to heat After heating the extract solution to 108°C, send it to the fourth-stage preheater 5, use the condensed water in the first-effect condensate bucket 1 to heat the extract solution in the fourth-stage preheater 5 to 120°C and send it to the first-effect evaporation In the tank heating chamber 2; the...

Embodiment 3

[0036] A. The leaching solution of potassium-containing sintering soot ash (potassium chloride content is 270g / l, sodium chloride content is 65g / l) is sent into the primary preheater 10 through the delivery pipe 19, and is evaporated by three effects The secondary steam produced by the tank 9 and the flash steam produced by the flash tank 24 heat the leach solution in the primary preheater 10 to 55°C, send it to the secondary preheater 8, and use the second effect evaporation tank 7 to generate After the secondary steam in the secondary preheater 8 is heated to 80°C, it is sent to the tertiary preheater 6, and the secondary steam generated by the first-effect evaporator 3 is used to heat After the extract solution is heated to 102°C, it is sent to the fourth-stage preheater 5, and the condensate in the first-effect condensate bucket 1 is used to heat the extract solution in the fourth-stage preheater 5 to 119°C and sent to the first-effect evaporation In the tank heating chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com