A method of using manganese-containing fume as a catalyst for iron removal in goethite method

A goethite method for iron removal and catalyst technology is applied in the field of non-ferrous metal metallurgy, which can solve the problems of low ferrous ion oxidation efficiency and the like, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

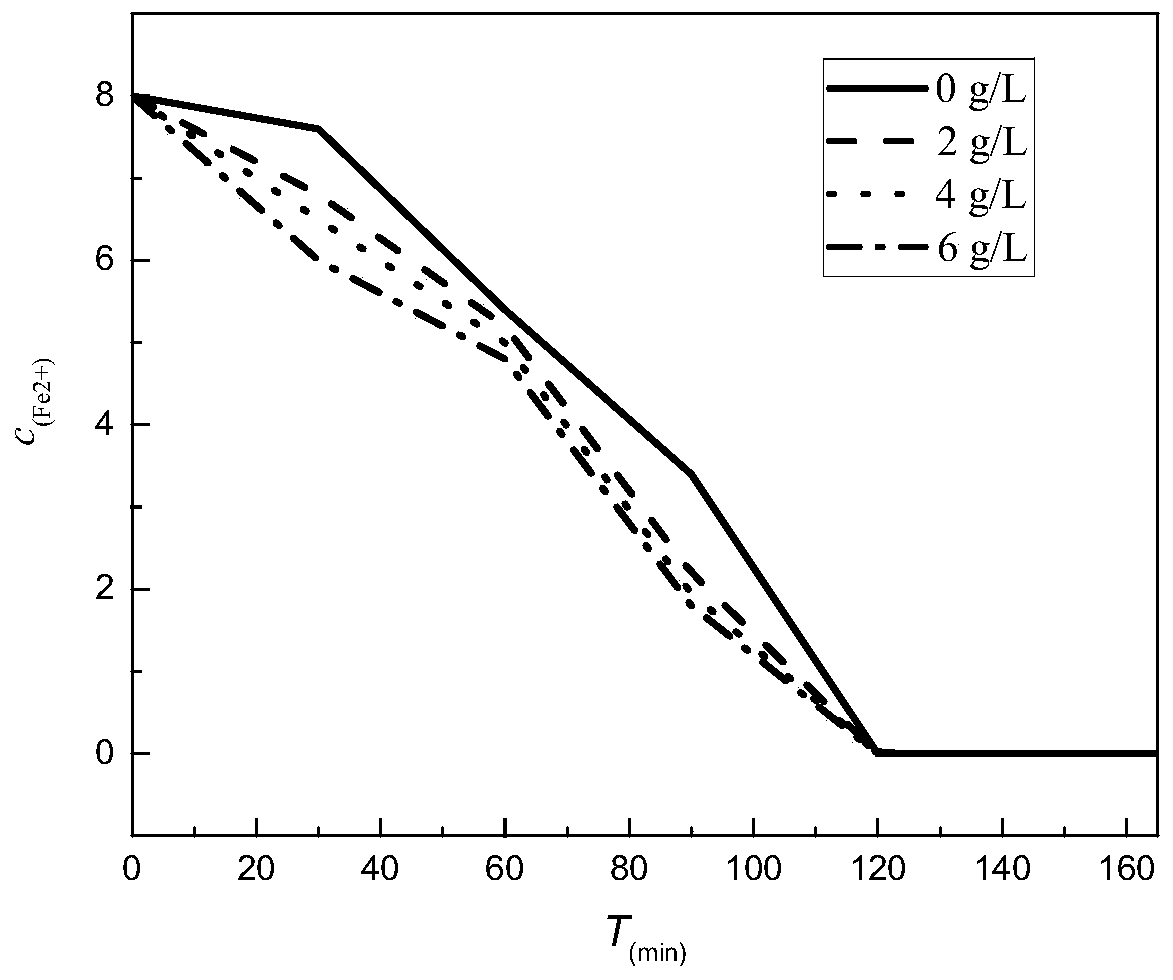

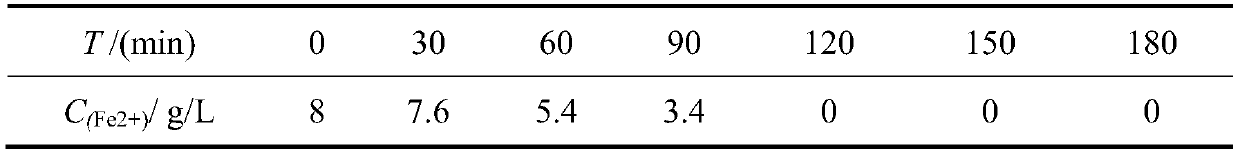

[0024] Simulate the preparation of iron-containing solution in the process of zinc smelting, in which Zn 2+ 140g / L, Fe 2+ 8g / L, Fe 3+ 2g / L,H 2 SO 4 18g / L, feed compressed air into the reaction solution at a flow rate of 0.6L / min, control the reaction temperature at 80°C, control the stirring speed of the solution at 1000r / min, and add 10% sodium carbonate solution through a numerically controlled pH automatic replenishment machine into the reaction solution to timely and accurately control the pH of the reaction solution within the range of 2 to 3.5. In this embodiment, the addition amount of manganese-containing fumes is 0 g / L. The ferrous ion content in the solution in different time periods under this condition is listed in Table 1.

[0025] The content of ferrous ions in the solution in different reaction time periods of table 1

[0026]

Embodiment 2

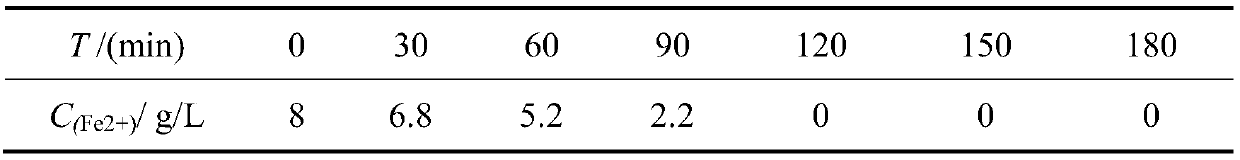

[0028] The addition of manganese-containing soot is 2g / L, and other conditions are consistent with those in Example 1. Under this condition, the content of ferrous ions in the solution in different reaction time periods was investigated, and the results are shown in Table 2.

[0029] The content of ferrous ion in the solution in table 2 different reaction time periods

[0030]

Embodiment 3

[0032] In this embodiment, the addition amount of manganese-containing fumes is 4g / L, and the rest of the conditions are kept consistent with the above-mentioned embodiments. The content of ferrous ions in the solution in different reaction time periods under this condition is shown in Table 3.

[0033] The content of ferrous ions in the solution in different reaction time periods of table 3

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com