Method for Carbon Sequestration in High Alkaline Alumina Red Mud

A technology of alumina and high alkalinity, applied in the direction of ammonium carbonate/acid carbonate, etc., can solve the problems of breaking the balance of soil pH, changing the hardness of groundwater, and destroying the ecological environment, achieving good carbon sequestration effect, Improved reactivity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The raw material ratio of alumina red mud carbon fixation: 25.0kg of ground red mud, 2.5kg of quicklime, 10.0kg of ammonium dihydrogen phosphate and 12.5kg of water.

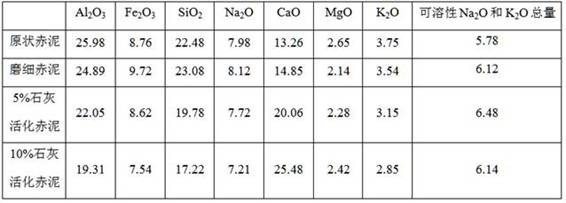

[0035] (1) Preparation of raw materials: dry the undisturbed alumina red mud, grind it through a 150 μm square-hole sieve for use; industrial grade ammonium dihydrogen phosphate; calcareous quicklime powder; ordinary drinking water; test undisturbed red mud, ground red mud and Chemical composition and soluble potassium and sodium ion content of activated red mud, and converted into soluble Na 2 O and K 2 The total amount of O, test and calculation results are shown in Table 1.

[0036]Table 1 The chemical composition mass percentage and total amount of soluble potassium and sodium oxides of undisturbed red mud, ground red mud and activated red mud.

[0037]

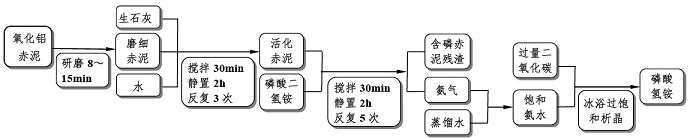

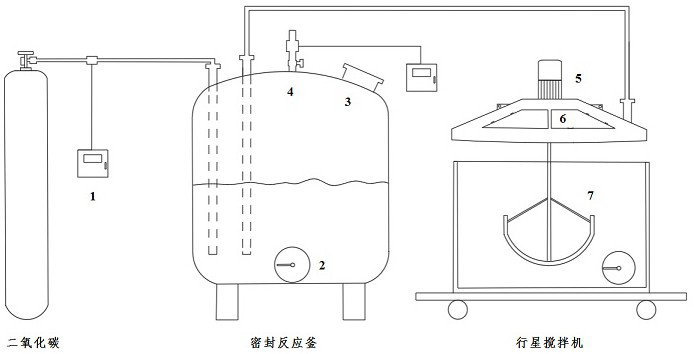

[0038] (2) Ammonia gas collection: according to figure 1 The process flow of alumina red mud carbon fixation is shown, using figure 2 The eq...

Embodiment 2

[0046] The ratio of raw materials for carbon fixation of alumina red mud: 25.0kg of ground red mud, 5.0kg of quicklime, 12.5kg of ammonium dihydrogen phosphate and 7.5kg of water.

[0047] Except for the mixing ratio, other processes are the same as in Example 1. After the weighing test, using the mixing ratio and process of Example 2, 25kg of activated alumina red mud can fix 2080L (4.15kg) of carbon dioxide gas to obtain 8.02kg of ammonium bicarbonate and 46.5kg of phosphorus-containing red mud (water content 20.2%) .

Embodiment 3

[0049] The ratio of raw materials for carbon fixation of alumina red mud: 25.0kg of ground red mud, 4.0kg of quicklime, 9.0kg of ammonium dihydrogen phosphate and 12.0kg of water.

[0050] Except for the mixing ratio, other processes are the same as in Example 1.

[0051] After the weighing test, using the mixing ratio and process of the implementation case 3 of the present invention, 25kg of activated alumina red mud can fix 1490L (2.95kg) of carbon dioxide gas, and obtain 5.90kg of ammonium bicarbonate and 48.1kg of phosphorus-containing red mud (water content). 24.6%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com