Continuous stamping die for end cover bottom plate of automobile heater motor

A technology for heating motors and stamping dies, applied in the field of stamping dies, which can solve the problems of complex base plate die structure, high production cost, and high energy consumption, reduce the turnover process of molding equipment and semi-finished products, improve production efficiency and product quality, The effect of production management and quality control improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

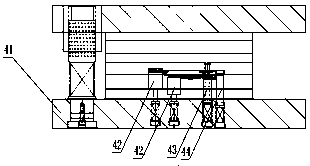

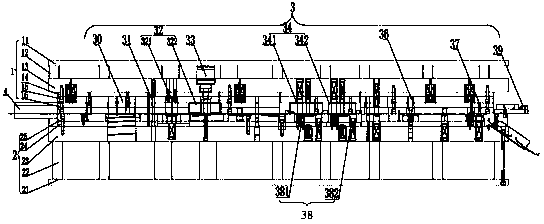

[0025] Such as figure 1 As shown, a continuous stamping die for the end cover bottom plate of an automobile heater motor includes an upper mold part 1, a lower mold part 2, a cylinder forming part 3, and a feeding mechanism 4; the upper mold part includes an upper cover plate 11 assembled in sequence, Upper foot 12, upper mold base 13, upper backing plate 14, upper fixing plate 15, unloading plate 16; the lower mold part includes lower supporting plate 21, lower supporting foot 22, lower mold base 23, lower backing plate assembled in sequence 24. The lower fixed plate 25 and the die plate; the cylinder forming part includes a tearing punch 30 arranged in sequence on the upper mold part, an in-mold misfeed detection device 31 controlled by PLC, a first forming punch 321, a second Forming punch 322, spring 33, first flanging shaping punch 341, second flanging shaping punch 342, punching die, turning die 36, blanking die 37, and the first flanging that is arranged on the lower mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com