Potassium borohydride-ammonium chloride reduction recovery method for platinum in laboratory waste precious metal materials

A technology of potassium borohydride and ammonium chloride, applied in the field of precious metal recovery, can solve problems such as difficult operation, high risk, and difficult preservation, and achieve the effects of avoiding waste and loss, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

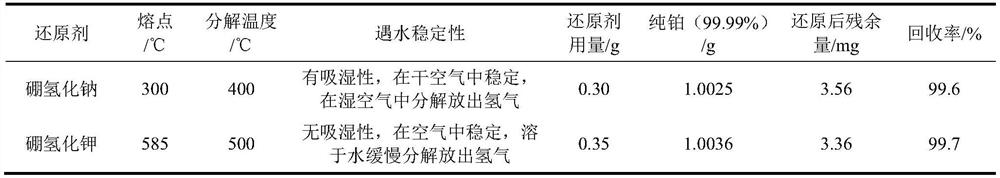

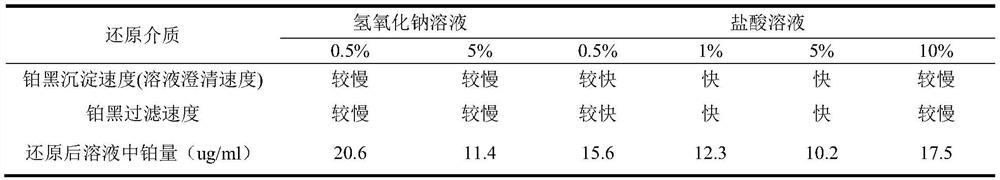

[0019] The potassium borohydride-ammonium chloride reduction recovery method of platinum in the laboratory waste precious metal material of the present embodiment is as follows:

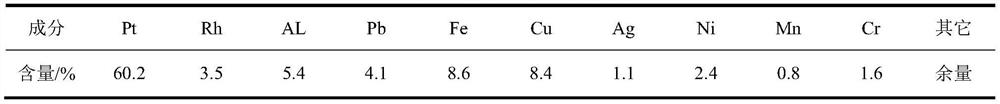

[0020] (1) Dissolution of platinum in the sample

[0021] Weigh 20.0 grams of experimental raw materials, put them into a 500 ml beaker, add 100 ml of distilled water, slowly add nitric acid with a volume ratio of 1:1, and keep stirring until no bubbles appear in the solution, then continue to add about 50 ml in excess, and Control the total volume to about 200 milliliters, heat and dissolve to remove metals such as copper, lead, and aluminum that are soluble in nitric acid in the raw material, remove and cool, place for clarification, and pour off the supernatant. Add about 100 ml of aqua regia to the residue, place on a hot plate at 120°C to slightly boil to dissolve, and continuously add aqua regia until the platinum is fully dissolved. Continue to boil and heat the solution to a small volume, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com