Sodium methyl mercaptide production process and device

A kind of sodium methyl mercaptide, the technology of production process, is applied in the process and the corresponding device field of producing sodium methyl mercaptide solution by utilizing refined methyl mercaptan, can solve the problems such as potential safety hazard, processing difficulty, big environmental impact, achieve the reduction of production capacity consumption, good product quality and low sulfide impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

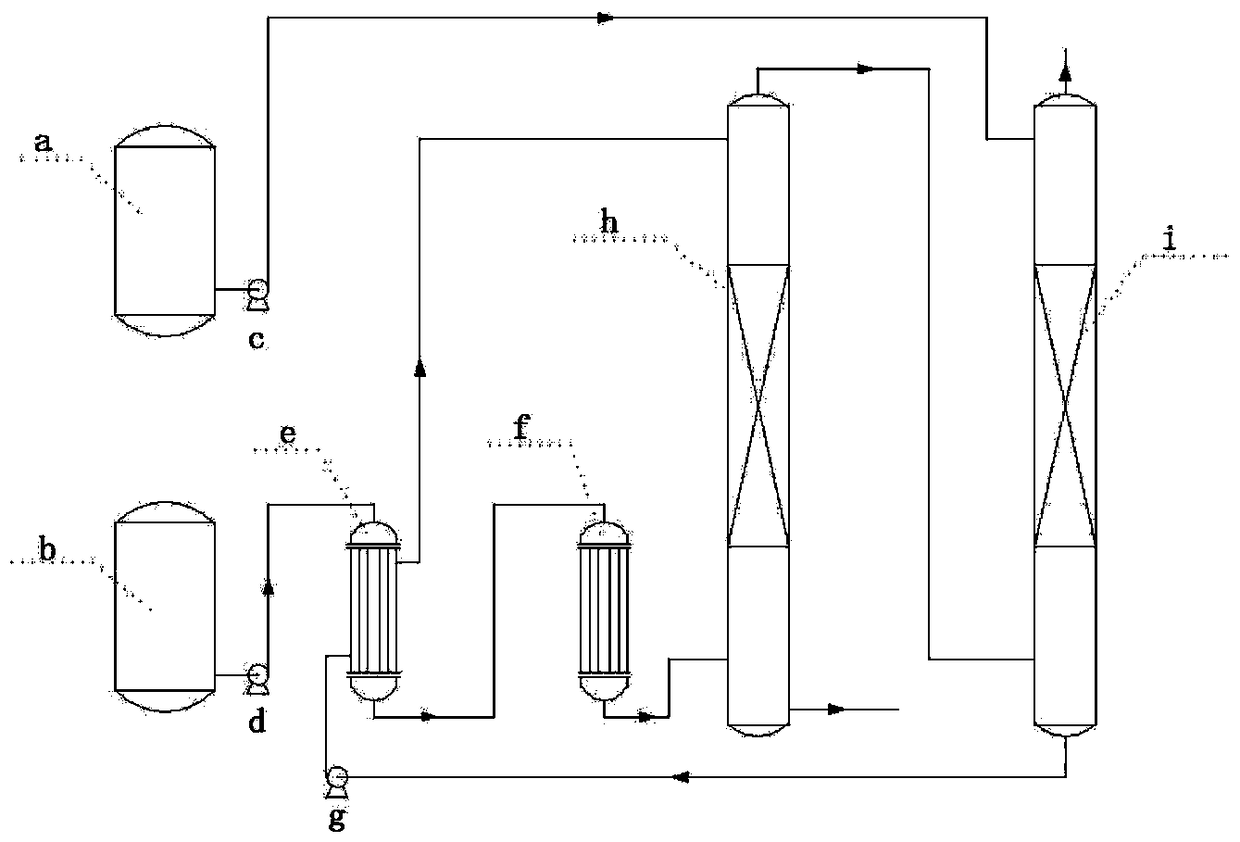

[0034] A sodium methyl mercaptide production device, the device used in the process at least includes the following equipment: liquid caustic soda storage tank, methyl mercaptan storage tank, heat exchanger, absorption tower, machine pump, and each device is connected as follows:

[0035] The liquid caustic soda storage tank a is connected to the alkali feed port on the upper part of the secondary absorption tower i through the alkali feed pump c; the bottom extraction port of the secondary absorption tower i is connected to the shell layer feed port of the primary heat exchanger e through the intermediate pump g; The shell outlet of the primary heat exchanger e is connected to the upper feed port of the primary absorption tower h through a pipeline;

[0036] The methyl mercaptan storage tank b is connected to the feed port of the primary heat exchanger e tube side through the methyl mercaptan feed pump d; The feed port is connected; the outlet of the tube side of the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com