Waste gas treatment and methyl mercaptan recycling process in cimetidine and ranitidine production

A technology of ranitidine and cimetidine, which is applied in the field of waste gas treatment and methyl mercaptan recovery technology, can solve the problems of chemical production safety hazards, burnout of incinerators, air pollution, etc., achieve circular economy and avoid waste gas Emissions, the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Taking the production of cimetidine technical in a pharmaceutical factory as an example, a total of 35 kg of waste gas is produced per hour during the condensation and amination process, so the daily waste gas is 840 kg, and the waste gas contains 96.0% of methyl mercaptan in terms of mass percentage. Dimethyl sulfide 2.0%, monomethylamine 1%, carbon disulfide 1%.

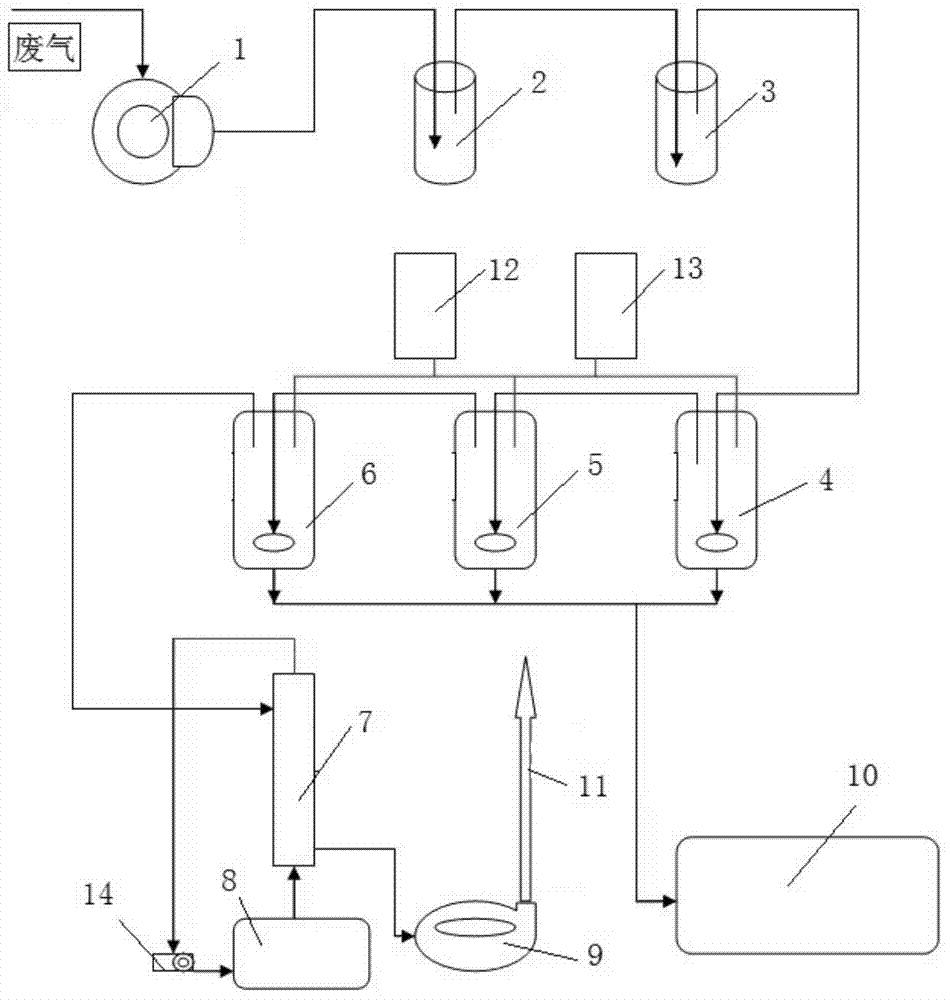

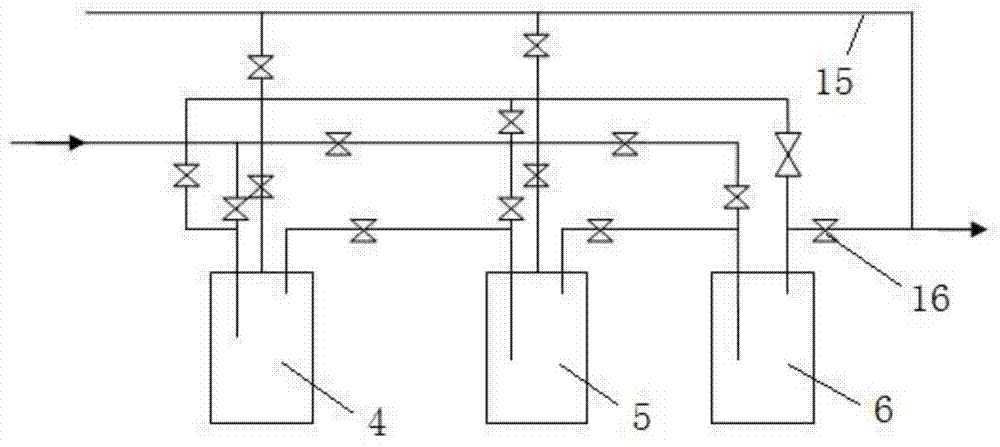

[0032] Such as figure 1 As shown, it is used for waste gas treatment and methyl mercaptan recovery device, including a water washing tank 2, an alkali washing tank 3, a primary absorption tank 4, a secondary absorption tank 5 and a tertiary absorption tank 6 connected in sequence through pipelines. The inlet end of the tank 2 is connected with the mechanical vacuum pump 1 through a pipeline, and the waste gas is introduced into the washing tank 2 through the mechanical vacuum pump 1; the upper ends of the primary absorption tank 4, the secondary absorption tank 5 and the tertiary absorption tank 6 are Link ...

Embodiment 2

[0045] A chemical factory produces 1-methylamino-1-methylthio-2-nitroethylene, an intermediate of ranitidine, and produces 20 kg of waste gas per hour, so the daily waste gas is 480 kg. The waste gas contains Methyl mercaptan 97.0%, dimethyl sulfide 1.5%, monomethylamine 1%, carbon disulfide 0.5%.

[0046] The equipment used for waste gas treatment and methyl mercaptan recovery is the same as in Example 1.

[0047] The specific treatment process is as follows:

[0048] (1) The exhaust gas from the workshop is sucked and collected through the intake pipe of the mechanical vacuum pump, and then pressurized through the exhaust pipe into the treatment and absorption section, and the mechanical impurities in the gas are filtered out at the front end of the suction pipe;

[0049] (2) Waste gas is introduced in the washing tank, and the control pressure is 0.3MPa, and the temperature of water in the washing tank is 10°C, and the volatile substance monomethylamine easily soluble in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com