Production method and apparatus of dimethyl disulfide

A technology for the production of dimethyl disulfide, which is applied in the field of preparation of dimethyl disulfide, can solve the problems of low investment costs, and achieve the effects of low consumption, stable production process, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

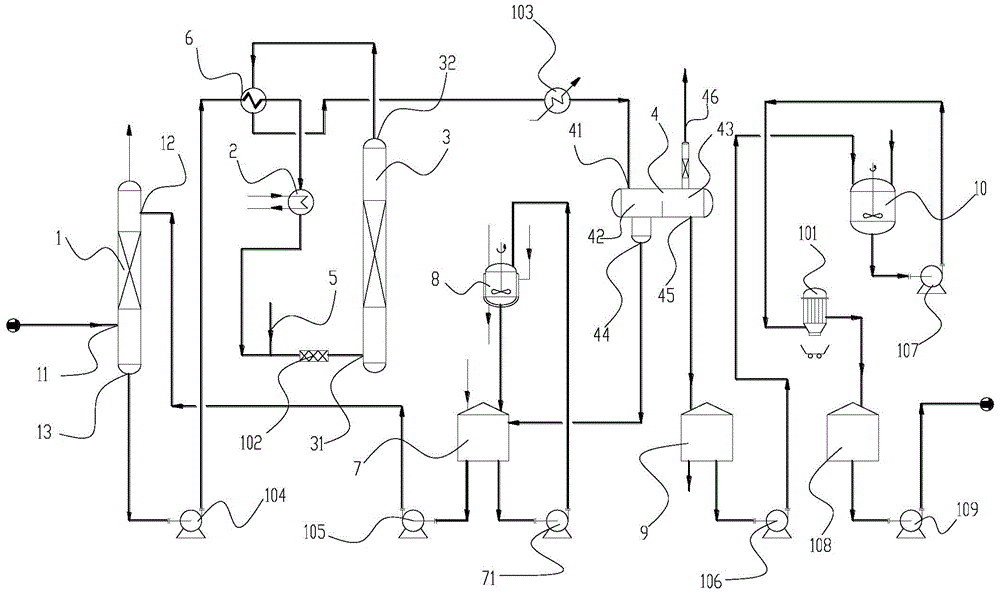

Image

Examples

Embodiment 1

[0058] The first step is to make a packed reaction tower with DN100×3000 steel pipe and DN150×3000 jacket steel pipe, as well as material inlet and outlet pipes, flange pressure gauges, and thermometers. This reaction tower can be used for the absorption of methyl mercaptan , can also be used as the oxidation of sodium methyl mercaptide;

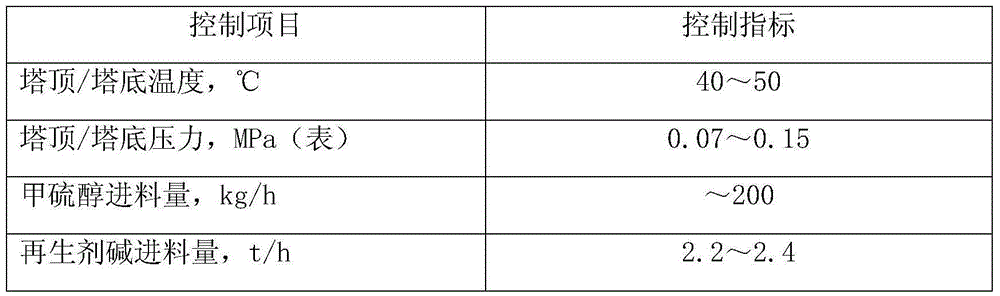

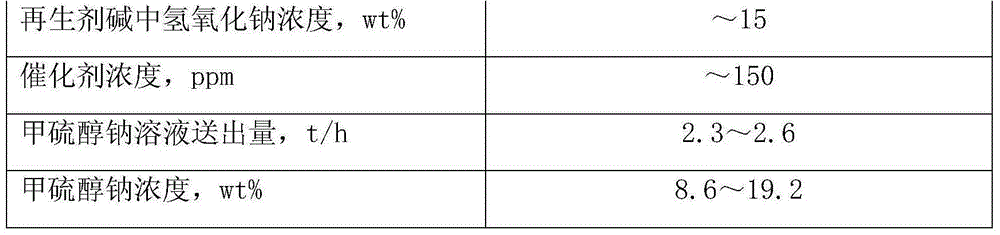

[0059] The second step, preparation of alkali solution: first prepare 10-20% sodium hydroxide solution, then add 100-200ppm of catalyst, and put it into the reaction tower;

[0060] The 3rd step, pass into methyl mercaptan to reaction tower, after absorbing certain hour, stop passing through methyl mercaptan, analyze the concentration of sodium methyl mercaptide in the assay agent lye;

[0061] In the fourth step, hot water is passed into the jacket layer of the reaction tower, and when the temperature reaches the set temperature of the test, the hot water is stopped. Feed 50% (mol) oxygen-enriched air into the reaction tower or increase th...

Embodiment 2

[0066] It is an industrial scale-up verification test. Since there is no ready-made methyl mercaptan gas during the industrial scale-up verification test, the raw material gas of methyl mercaptan is prepared by adding dilute sulfuric acid from an outsourced sodium methyl mercaptide solution, and is temporarily replaced by two neutralization tanks with stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com