Production technology of high-purity sodium methyl mercaptide

A technology of sodium methyl mercaptide and production process, which is applied in the field of production technology of high-purity sodium methyl mercaptide, can solve the problems of high transportation cost, high use cost and high impurity content, and achieves reduction of equipment investment and operation cost, and reduction of transportation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

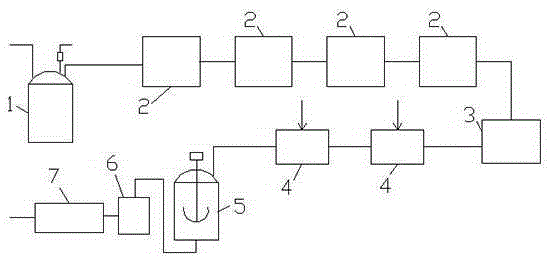

[0015] As shown in the figure, a kind of production technique of high-purity sodium methyl mercaptide, concrete process steps are as follows:

[0016] (1) Reaction: Pre-add a quantitative amount of sodium hydrosulfide with a mass content of about 32% into the reactor, and then continuously and uniformly add 98% of dimethyl sulfate, dimethyl sulfate and sodium methyl mercaptide into the reactor The reaction produces methyl mercaptan and sodium sulfate, the reaction temperature is controlled at about 75°C, and the pressure is controlled at a slight positive pressure or a slight negative pressure;

[0017] (2) Alkali absorption: The reacted methyl mercaptan gas is washed to remove impurities in four stages, and then the water is removed by cyclone separation. The pure methyl mercaptan gas after removing impurities is absorbed by two stages of alkali to generate methyl sulfide Sodium alkoxide solution, using the difference in solubility of sodium methyl mercaptide at different tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com