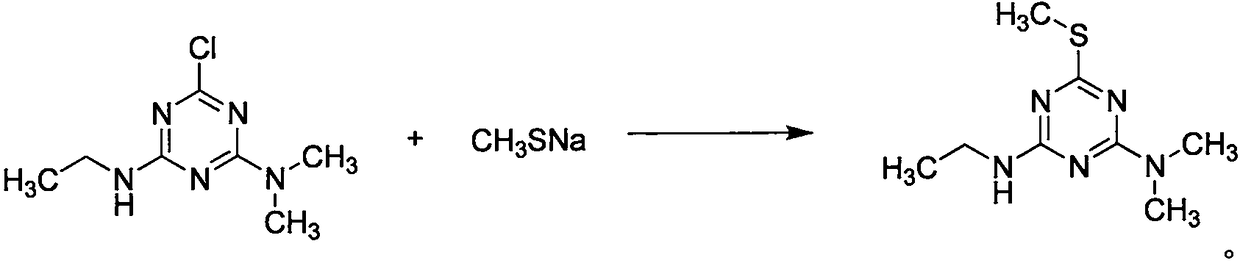

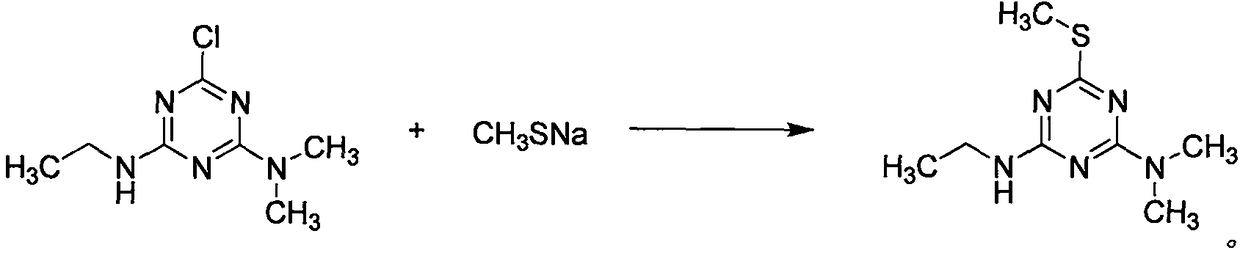

Catalyst-free ametryn production method

A production method, the technology of arazine, which is applied in the field of catalyst-free arazine production, can solve the problems of long reaction cycle, large amount of waste water, easy pollution of the environment, etc., achieve good economic and social benefits, reduce environmental pressure, reduce The effect of raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A catalyst-free method for the production of ametryn is as follows:

[0023] Into a 1000ml pressure reactor, add 100g of 97% atrazine, 165g of 20% sodium methyl mercaptide, 200g of isopropanol, seal the pressure reactor, heat up to 110°C, the reaction pressure is 0.4MPa, and the reaction time is 2h After the reaction, the temperature was lowered, the layers were left to stand, the organic phase was distilled to recover the solvent, and the remaining molten material was put into a tray, cooled and crystallized to obtain 101 g of methionine, with a content of 97.2%.

Embodiment 2

[0025] A catalyst-free method for the production of ametryn is as follows:

[0026] In a 1000ml pressure reactor, add 100g of 97% atrazine, 165g of 20% sodium methyl mercaptide, 200g of isopropanol recovered from the above, seal the pressure reactor, heat up to 110°C, and the reaction pressure is 0.4MPa. After 2 hours of reaction, the temperature was lowered, the layers were left to stand, and the organic phase was distilled to recover the solvent. The remaining molten material was put into a tray, cooled and crystallized, and 100 g of arazine was obtained, with a content of 97.3%.

Embodiment 3

[0028] A catalyst-free method for the production of ametryn is as follows:

[0029] In a 1000ml pressure reactor, add 100g of 97% atrazine, 165g of 20% sodium methyl mercaptide, 200g of isopropanol, seal the pressure reactor, heat up to 120°C, the reaction pressure is 0.5MPa, and the reaction time is 2h After the reaction, the temperature was lowered, the layers were left to stand, the organic phase was distilled to recover the solvent, the remaining molten material was put into a tray, cooled and crystallized, 101.3 g of arazine, the content of which was 97.24%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com