Sodium methyl mercaptide production environment-protecting processing device and technology

A technology for sodium methyl mercaptan and environmental protection treatment, which is applied in natural water treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Low operating costs, lower production costs, and improved environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

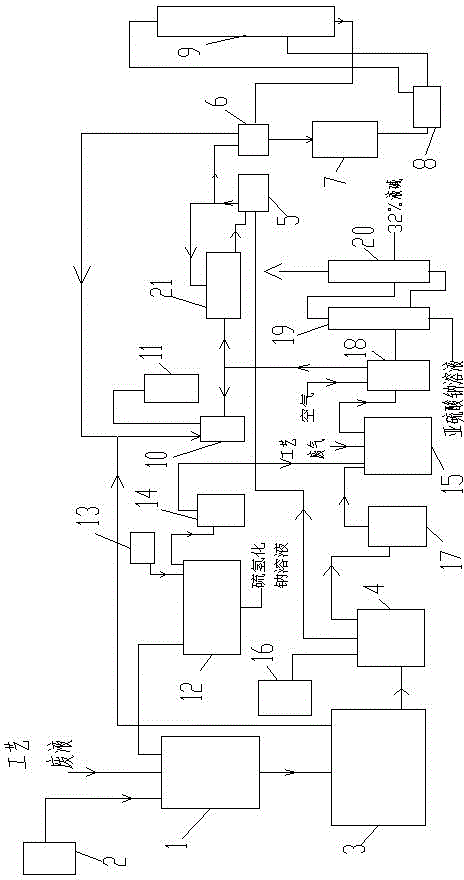

[0019] As shown in the figure, an environmental protection treatment device for the production of sodium methyl mercaptide includes a process waste liquid treatment mechanism and a process waste gas treatment mechanism. The process waste gas treatment mechanism is mainly composed of a burner 15, an air preheater 18, a front absorption tower 19 and a rear The absorption tower 20 is composed of the sodium methyl mercaptide process waste gas pipe connected to the burner 15, the burner 15 is connected to the front absorption tower 19 through the air preheater 18, the front absorption tower 19 is connected to the rear absorption tower 20, and the rear absorption tower 20 is connected to the rear absorption tower 20. A liquid caustic inlet pipe is connected, the air preheater 18 is a shell-and-tube structure, the shell side is fed with ambient air, and the tube side is passed through the flue gas of the burner; the process waste liquid treatment mechanism is mainly composed of an acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com