Production method of methyl mercaptan salt

A technology of methyl mercaptan and production method, which is applied in the fields of mercaptan preparation and organic chemistry, can solve the problems of incomplete reaction of methyl mercaptan, great safety hazards, unfavorable industrial production, etc., and meet market requirements and industrial production needs , Eliminate blocked pipes, eliminate bad smell effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

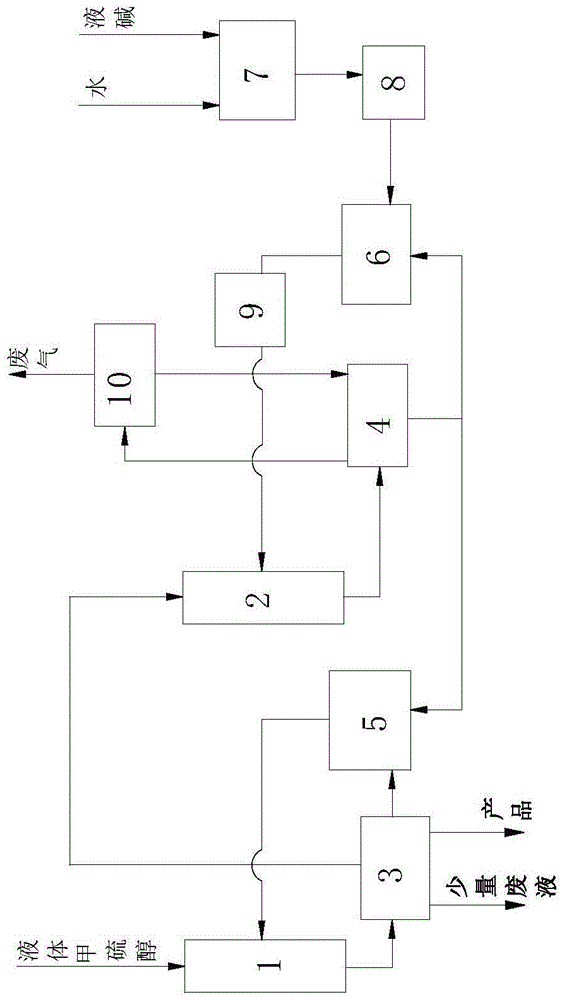

[0022] A kind of production method of methyl mercaptide, as attached figure 1 As shown, it specifically adopts the following reaction device, which includes a primary static mixer 1, a secondary static mixer 2, a primary kettle 3, a secondary kettle 4, a primary mixer 5, a secondary mixer 6, and a Alkali tank 7, primary preheater 8, secondary preheater 9 and gas-liquid separator 10; primary static mixer 1 communicates with liquid methyl mercaptan feed line, primary kettle 3 and primary mixer 5 respectively The primary kettle 3 is also communicated with the secondary static mixer 2, the primary mixer 5, the waste liquid discharge pipeline and the product discharge pipeline respectively; the primary mixer 5 is also connected with the secondary kettle 4; the secondary static mixing Device 2 is also communicated with secondary kettle 4 and secondary preheater 9 respectively; Secondary kettle 4 is also communicated with secondary mixer 6 and waste gas pipeline respectively; The se...

Embodiment 2

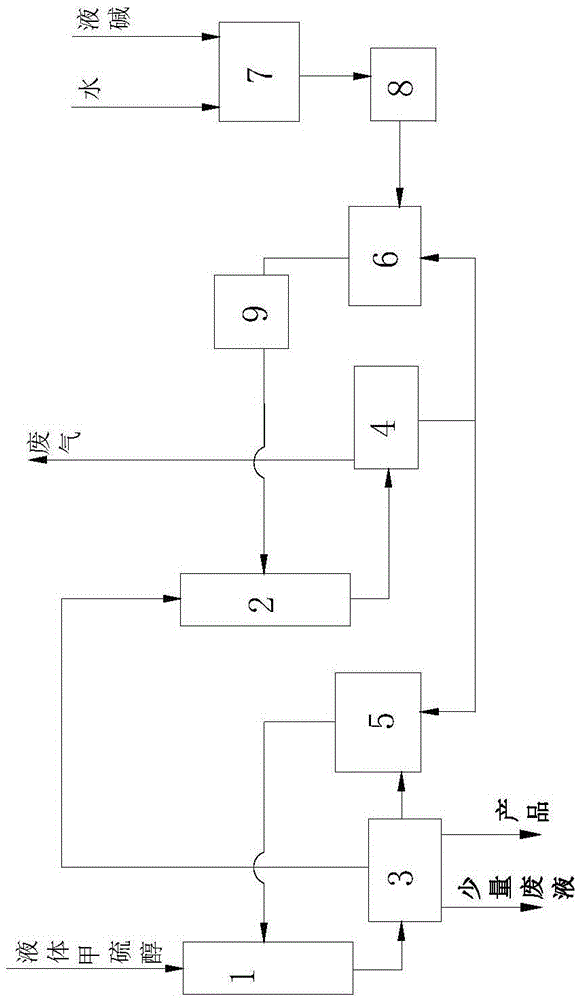

[0028] A kind of production method of methyl mercaptide, as attached figure 2As shown, it specifically adopts the following reaction device, which includes a primary static mixer 1, a secondary static mixer 2, a primary kettle 3, a secondary kettle 4, a primary mixer 5, a secondary mixer 6, and a Alkali tank 7, primary preheater 8 and secondary preheater 9; primary static mixer 1 communicates with liquid methyl mercaptan feed line, primary kettle 3 and primary mixer 5 respectively; primary kettle 3 It is also communicated with secondary static mixer 2, primary mixer 5, waste liquid discharge pipeline and product discharge pipeline respectively; primary mixer 5 is also communicated with secondary kettle 4; secondary static mixer 2 is also connected respectively with The secondary kettle 4 is communicated with the secondary preheater 9; the secondary kettle 4 is also communicated with the secondary mixer 6 and the waste gas pipeline respectively; the secondary mixer 6 is also c...

Embodiment 3

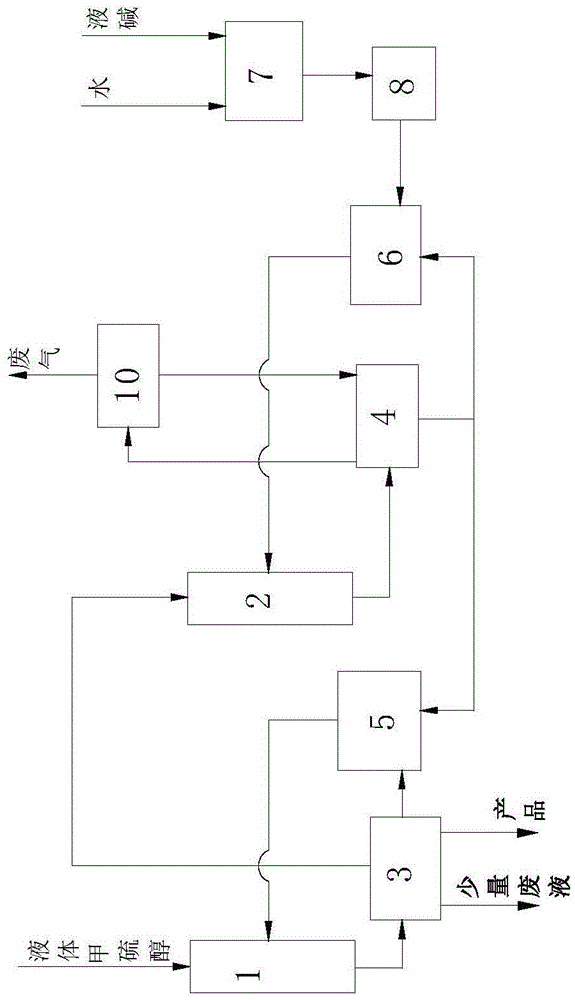

[0033] A kind of production method of methyl mercaptide, it specifically adopts the reaction unit described in embodiment 1, and carries out according to the following steps:

[0034] Liquid methyl mercaptan is added into the first-stage static mixer 1 through the feed line to be directly vaporized, and then passes through the alkali distribution tank 7, the first-stage preheater 8, the second-stage mixer 6, the second-stage preheater 9, The sodium hydroxide solution coming from the secondary static mixer 2, the secondary kettle 4, and the primary mixer 5 carries out the absorption reaction, and the reaction product containing sodium methyl mercaptide generated by the reaction is buffered in the primary kettle 3, and the absorption is not complete The methyl mercaptan gas overflows from the top of the primary kettle 3 and enters the secondary static mixer 2. In this step, the sodium hydroxide solution is preheated to 42° C. through the primary preheater 8, and the secondary pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com