Preparation method of ametryn

A technology of atrazine and atrazine, applied in the field of pesticides, can solve the problems of raw material sodium methyl mercaptan odor, physical and chemical method removal, unpleasant odor of atrazine products, etc., to improve product quality and production sites. environment, reduce the amount of three wastes, and eliminate the effect of high COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

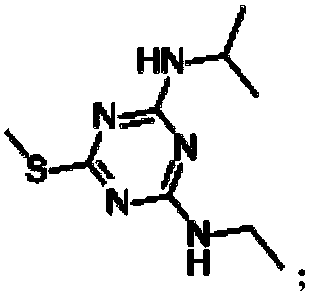

[0039] Fix 1.32g of ZSM-5 catalyst in a 1L autoclave with stirring and temperature controller, add 200g of 97% atrazine, 135.03g of isopropanol, 43.21g of methyl mercaptan, and seal it at a temperature of 90-110°C , stirred and reacted for 1 hour at a pressure of 0.49 to 0.78 to obtain an arazine wet material, which was dried at 105 to 115°C for 1 hour to obtain 206.11 g of an ametryn technical substance, and the arazine content was 99.05 g by HPLC. %, the yield based on atrazine is 99.90%, and the by-product 2-chloropropane is 70.91g, and the content is 99.56%.

[0040] The specific reaction parameters and results are shown in Table 4 and Table 5.

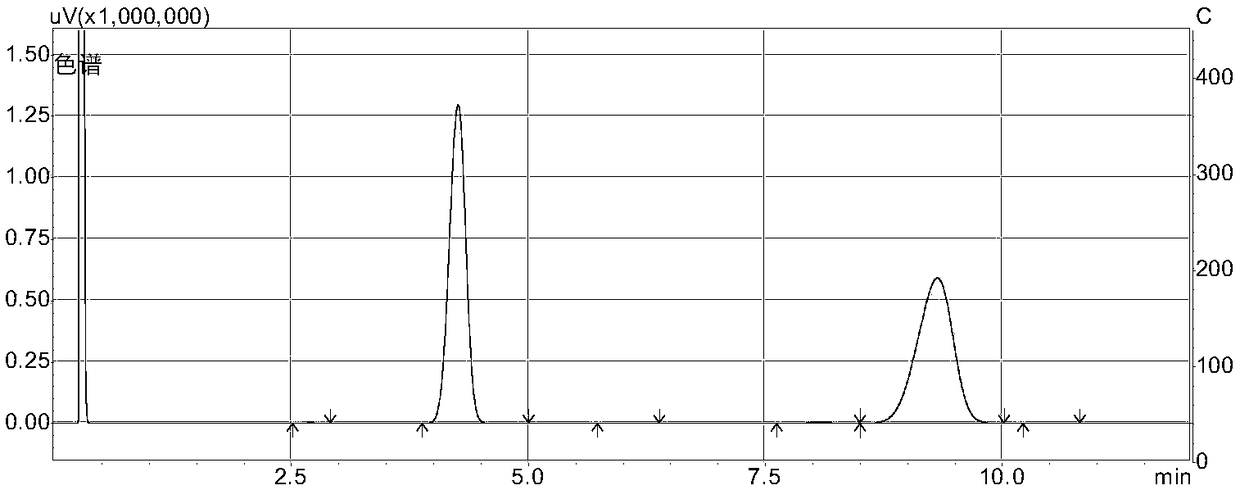

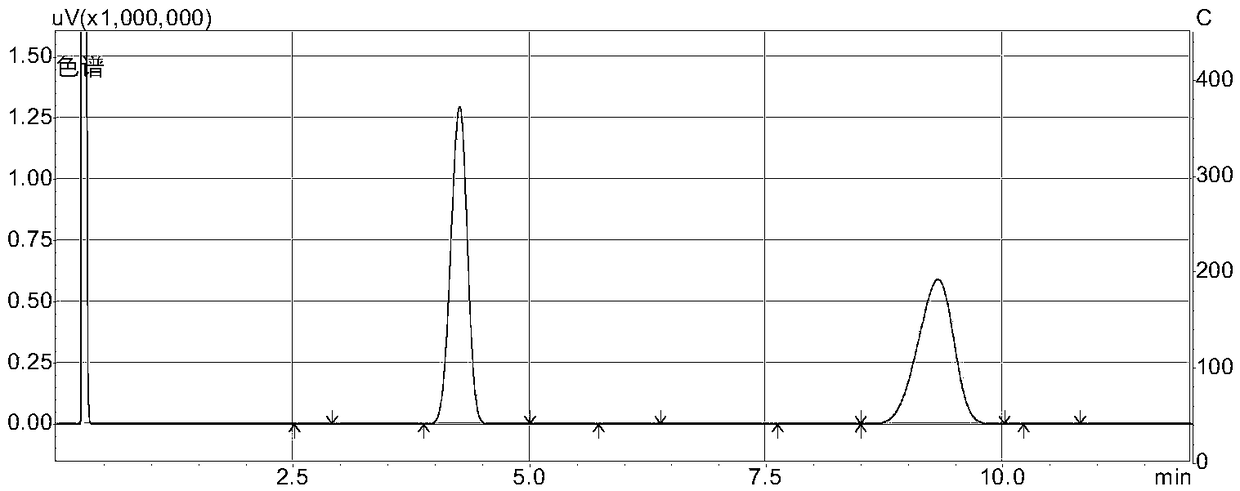

[0041] Weigh respectively the ametryn standard substance and the ametryn original drug prepared in Example 1, and adopt gas chromatography to detect the prepared ametryn original drug, and the results are as follows: figure 1 , figure 2 , Table 1 ~ Table 3 shown.

[0042] Table 1 Gas chromatographic data of the ametryn standar...

Embodiment 2~ Embodiment 10

[0049] The reaction steps are the same as in Example 1, and the specific reaction parameters and results are shown in Table 4 and Table 5.

[0050] Table 4 embodiment 1~10 reaction parameter and result summary

[0051]

[0052]

[0053] Table 5 embodiment 1~10 reaction parameter summary

[0054] Example

[0055] It can be seen from the above examples that the present invention has prepared ametrazine with high yield and purity, and no waste salt is produced in the production process, and the product has no pungent taste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com