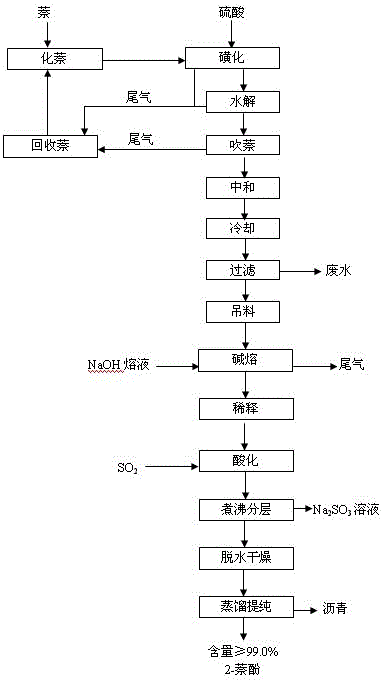

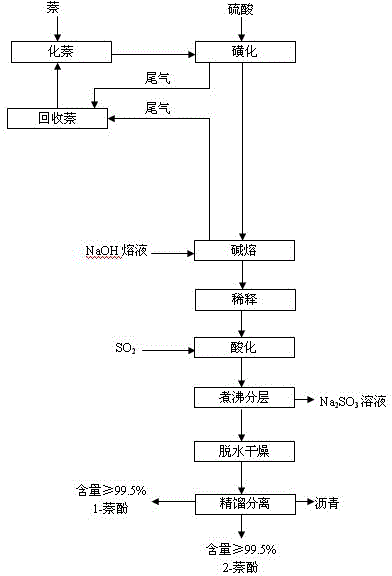

Method for cooperatively producing 1-naphthol and 2-naphthol from naphthalene sulfonation product by virtue of direct alkali fusion

A product, naphthol technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of repeated investment, serious corrosion of equipment, difficult treatment of filtered wastewater, etc., and achieve energy saving and human resources, closed The effect of a thorough improvement in operation and a thorough improvement in the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Sulfonation: Add 260.4 grams of naphthalene into a 500ml three-neck flask, heat up to about 80°C and start stirring after the naphthalene melts. At 80-90°C, add concentrated sulfuric acid dropwise according to the acid-naphthalene molar ratio of 1.1:1, and keep the reaction at 90-100°C for 3 hours. Distill under reduced pressure for 60 minutes at 85-95°C with a vacuum degree of 0.025-0.045Mpa. Then add naphthalene according to the total molar ratio of naphthalene to concentrated sulfuric acid 1.8:1, and keep reacting at 90-100°C for 3 hours. Distill under reduced pressure for 90 minutes at 85-95°C with a vacuum of 0.025-0.045MPa. The obtained liquid mixture of sulfonated products 1-naphthalenesulfonic acid and 2-naphthalenesulfonic acid is controlled at 90-100°C for alkali fusion.

[0028] (2) Alkali fusion: Add solid sodium hydroxide into the alkali fusion stainless steel pot, heat up to above 210°C and start stirring after complete melting. When the temperature...

Embodiment 2

[0032] (1) Sulfonation: Add 260.4 grams of naphthalene into a 500ml three-neck flask, heat up to about 80°C and start stirring after the naphthalene melts. Add concentrated sulfuric acid dropwise at 150-160°C according to the acid-naphthalene molar ratio of 1.6:1, and keep reacting for 2 hours at 155-165°C. Distill under reduced pressure at 150-160° C. for 30 minutes with a vacuum degree of 0.01-0.025 MPa. Then add naphthalene according to the total molar ratio of naphthalene to concentrated sulfuric acid 1.3:1, and keep reacting for 1 hour at 155-165°C. Distill under reduced pressure for 60 minutes at 150-160°C with a vacuum of 0.01-0.025MPa. The obtained liquid mixture of sulfonated products 1-naphthalenesulfonic acid and 2-naphthalenesulfonic acid is controlled at 150-160°C for alkali fusion.

[0033](2) Alkali fusion: Add solid sodium hydroxide into the alkali fusion stainless steel pot, heat up to above 210°C and start stirring after complete melting. When the temperat...

Embodiment 3

[0037] According to the technical process described in embodiment 1

[0038] (1) Sulfonation: Add 260.4 grams of naphthalene into a 500ml three-neck flask, heat up to about 80°C and start stirring after the naphthalene melts. Add concentrated sulfuric acid dropwise at 85-90°C according to the acid-naphthalene molar ratio of 1.2:1, and keep the reaction at 115-125°C for 2.5 hours. Distill under reduced pressure for 100 minutes at 120-123°C with a vacuum of 0.045-0.05MPa. Then add naphthalene according to the total molar ratio of naphthalene to concentrated sulfuric acid 1.5:1, and keep the reaction at 115-125°C for 2 hours. Distill under reduced pressure for 90 minutes at 130-133°C with a vacuum of 0.085-0.09MPa. Keep the obtained liquid mixture of sulfonated products 1-naphthalenesulfonic acid and 2-naphthalenesulfonic acid at 110-120°C for alkali fusion.

[0039] (2) Alkali fusion: Add solid sodium hydroxide into the alkali fusion stainless steel pot, heat up to above 210°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com