Preparation device and preparation method of 3-methylmercapto propionaldehyde

A technology for the preparation of methionaldehyde and equipment, applied in the direction of mercaptan preparation, thioether preparation, organic chemistry, etc., can solve the problem of reducing the purity and yield of 3-methylthiopropionaldehyde products, pungent taste, consumption Large energy and other issues, to avoid excessive local concentration, reduce the formation of by-products, and stabilize the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

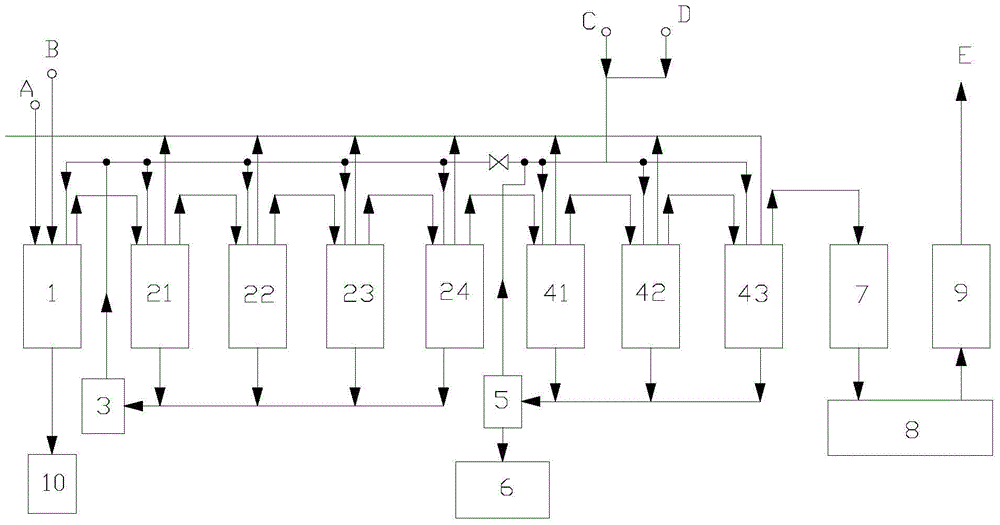

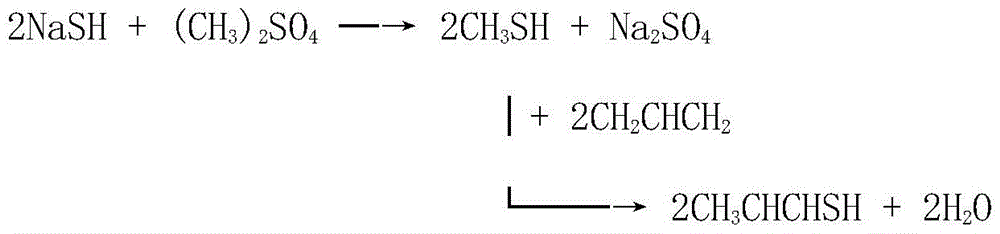

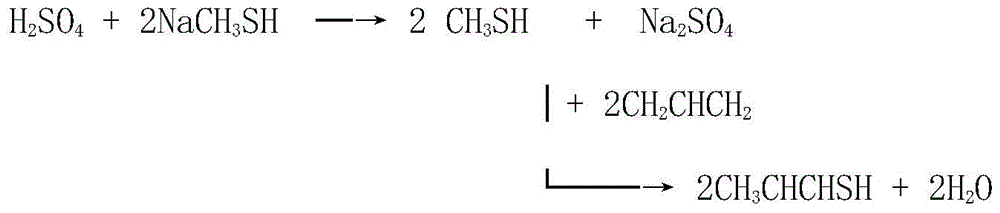

[0022] see figure 1 , The embodiment of the 3-methylthiopropanal preparation device is provided with a reaction kettle 1, 4 washing tanks (21-24), 3 washing circulation pumps, 3 absorption kettles (41-43), 5 absorption circulation pumps, Finished product tank 6, separation device 7, vacuum pump 8, tail gas treatment device 9, sewage treatment tank 10; The raw material inlet A and B of described reactor 1 are externally connected sodium hydrosulfide solution raw material source and dimethyl sulfate raw material source (as adopting The second technical scheme, the raw material inlets A and B of the reactor 1 are respectively externally connected to the sulfuric acid raw material source and the sodium methyl mercaptide raw material source), the methyl mercaptan outlet of the reactor 1 is connected to the methyl mercaptan inlet of the washing tank, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com