Method for co-producing sodium methyl mercaptide and dimethyl sulfide

A technology of dimethyl sulfide and sodium methyl mercaptide, which is applied in the chemical industry, can solve the problems of low conversion rate, difficult post-processing, high reaction temperature, etc., and achieve the effects of simple post-processing, high product yield, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

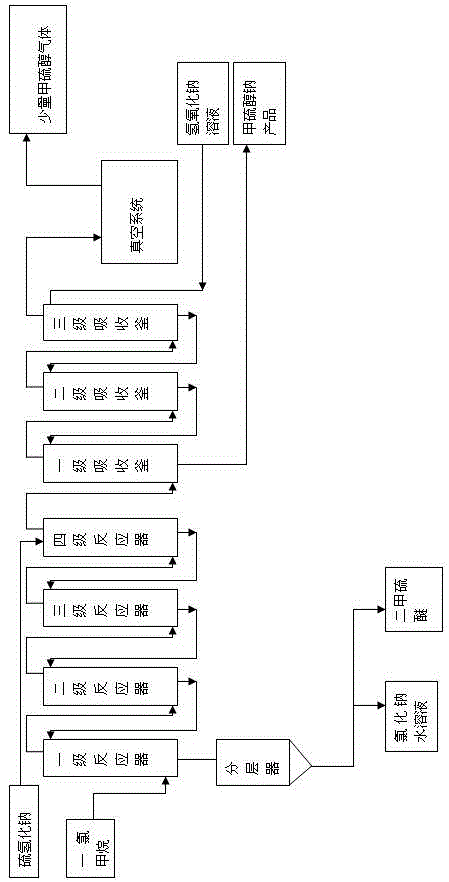

Image

Examples

Embodiment 1

[0031] A method for co-producing sodium methyl mercaptide and dimethyl sulfide, its specific steps comprising:

[0032] (1) Reaction stage: add an equal amount of 175Kg of sodium hydrosulfide solution with a mass fraction of 32% into four identical reactors to form a series connection. 60.6Kg of gas is passed into four reactors in turn to obtain pure methyl mercaptan gas;

[0033] (2) Absorption stage: add an equal amount of 296Kg of sodium hydroxide solution with a mass fraction of 13.5% into three identical absorption kettles, and the methyl mercaptan gas generated in step (1) is absorbed and saturated by sodium hydroxide solution in three stages After, can obtain massfraction and be 20.37% sodium methyl mercaptide solution 321Kg, yield 88.2%;

[0034] (3) Treatment stage: the reaction solution obtained in step (1) was introduced into a stratifier and allowed to stand still, and the oily liquid in the upper layer was taken to obtain a 9Kg dimethyl sulfide solution with a yi...

Embodiment 2

[0036] A method for co-producing sodium methyl mercaptide and dimethyl sulfide, its specific steps comprising:

[0037] (1) Reaction stage: add an equal amount of 124Kg of sodium hydrosulfide solution with a mass fraction of 45% into four identical reactors to form a series connection, at a pressure of -0.01Mpa and a temperature of 0°C, the Gas 75.7Kg is passed into four reactors in turn to obtain pure methyl mercaptan gas;

[0038](2) Absorption stage: add an equal amount of 267Kg of sodium hydroxide solution with a mass fraction of 15% into three identical absorption kettles, and the methyl mercaptan gas generated in step (1) is absorbed and saturated by sodium hydroxide solution in three stages After that, can obtain massfraction and be 289Kg of sodium methyl mercaptide solution 21.34%, yield 87.9%;

[0039] (3) Treatment stage: the reaction solution obtained in step (1) was introduced into a stratifier and left to stand, and the oily liquid in the upper layer was taken to...

Embodiment 3

[0041] A method for co-producing sodium methyl mercaptide and dimethyl sulfide, its specific steps comprising:

[0042] (1) Reaction stage: add an equal amount of 28% sodium hydrosulfide solution 200Kg into four identical reactors to form a series connection, at a pressure of -0.015Mpa and a temperature of 15°C The gas 141.4Kg is passed into four reactors in sequence to obtain pure methyl mercaptan gas;

[0043] (2) Absorption stage: add an equal amount of 14% sodium hydroxide solution 800Kg into three identical absorption kettles, and the methyl mercaptan gas generated in step (1) is absorbed and saturated by the sodium hydroxide solution in three stages After, can obtain massfraction and be 20.56% sodium methyl mercaptide solution 840Kg, yield 88.3%;

[0044] (3) Treatment stage: the reaction solution obtained in step (1) was introduced into a stratifier and left to stand, and the upper layer of oily liquid was taken to obtain 18Kg of dimethyl sulfide solution with a yield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com