Preparation method of 1,2-Dimethyl-3-methylsulfanyl-benzene

A technology of dimethyl anisole and nitro-o-xylene, applied in the field of preparation, can solve the problems of difficult "three wastes" treatment, high raw material prices, and high production costs, and achieves the advantages of being beneficial to industrialized production and the content of products. High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

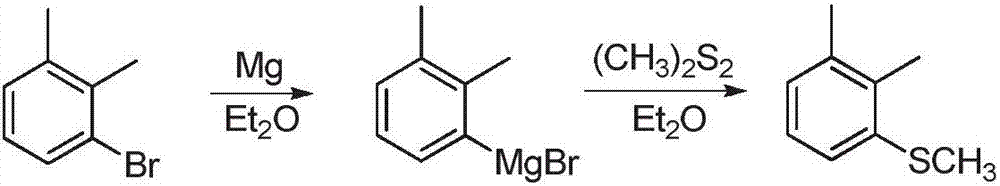

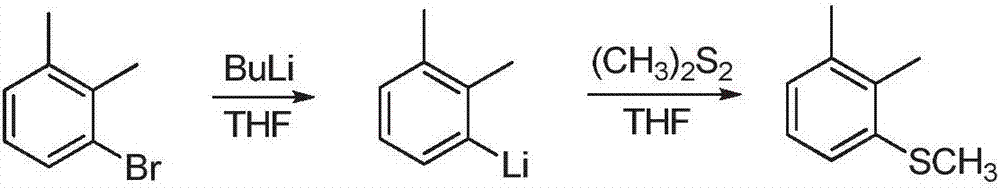

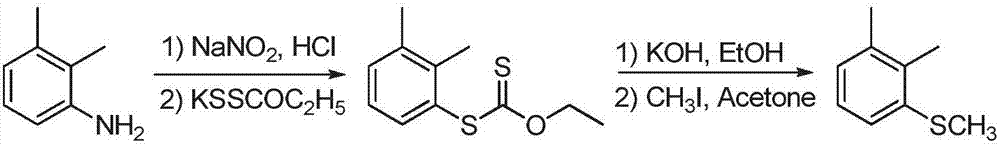

Method used

Image

Examples

Embodiment 1

[0033] Under nitrogen protection, 61.1g (99%, 0.4mol) 3-nitro-o-xylene, 32.5g (95%, 0.44mol) sodium methyl mercaptide, 0.072g (98%, 0.0004mol) Nickel acetate, 1g (99%, 0.004mol) triphenylphosphine and 427.7g acetone were heated to 50°C and then kept for 20h. After the reaction, add water and toluene, separate the layers, dry the organic phase, and remove the solvent. The residue is rectified in a ceramic random packed tower, and 55.2 g of light yellow liquid 2,3-Di Tolyl sulfide, content 98.2%, yield 89%. 1 H NMR (CDCl 3 , 300MHz) δ: 2.29 (s, 6H, ArCH 3 ×2), 2.44(s, 3H, ArSCH 3 ), 6.97 (dd, J=6.9Hz, J=2.1Hz, 1H, C 6 h 3 -H), 7.03~7.12(m, 2H, C 6 h 2 ).GC-MS (m / z): 152.1 (M + ), 138, 105.1, 77, 45.

Embodiment 2

[0035] Under nitrogen protection, 61.1g (99%, 0.4mol) 3-nitro-o-xylene, 38.4g (95%, 0.52mol) sodium methyl mercaptide, 0.9g (98%, 0.004mol) Nickel bromide, 2.6g (99%, 0.008mol) tetrabutylammonium bromide and 244.4g N,N-dimethylformamide were heated to 70°C and then kept for reaction for 15 hours. After the reaction, add water and toluene, separate the layers, dry the organic phase, and remove the solvent. The residue is rectified in a ceramic random packed tower, and 53.1 g of light yellow liquid 2,3-bis Tolyl sulfide, content 98%, yield 85.5%.

Embodiment 3

[0037] Under nitrogen protection, 61.1g (99%, 0.4mol) 3-nitro-o-xylene, 59g (95%, 0.8mol) sodium methyl mercaptide, 2.6g (99%, 0.02mol) chlorine Nickel chloride, 0.16g (99%, 0.0004mol) methyl trioctyl ammonium chloride and 122.2g N,N-dimethylacetamide were heated to 80°C and then kept for 10h. After the reaction, add water and toluene, separate the layers, dry the organic phase, and remove the solvent. The residue is rectified in a ceramic random packed tower, and 53.4 g of light yellow liquid 2,3-bis Tolyl sulfide, content 98.5%, yield 86.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com