A kind of ternary boride and its preparation method and application

A ternary boride and element technology, applied in welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of poor wear resistance, easy falling off, poor hardness, etc., and achieve good bonding strength, not easy to fall off, and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

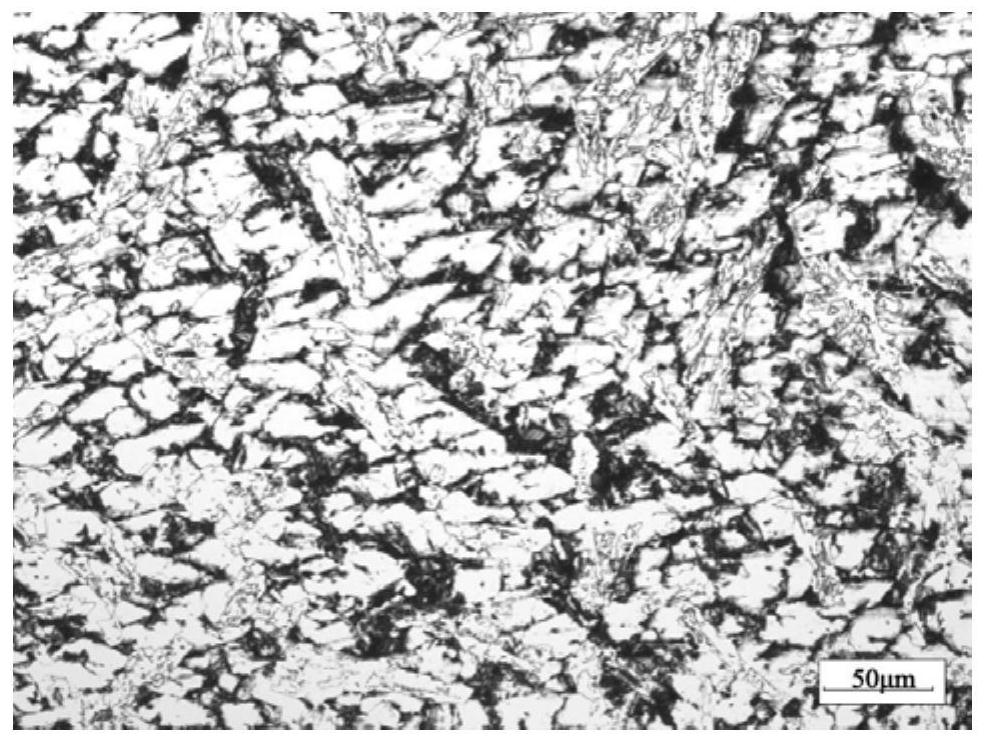

Image

Examples

Embodiment 1

[0044] The present embodiment provides a kind of ternary boride, and its raw material comprises 195g ferroboron powder, 625g ferromolybdenum powder, 130g chromium powder, 20g ferrosilicon powder, 20g nickel powder and 10g ferromanganese powder; Wherein, boron mass content is 3.66%, the mass content of silicon element is 1.18%, the mass content of iron element is 40.3%, the mass content of molybdenum element is 39.36%, the mass content of chromium element is 12.89%, the mass content of nickel element is 2%, the mass content of manganese element is 0.55% .

[0045] The preparation method of above-mentioned ternary boride comprises,

[0046]Weigh each raw material according to the above-mentioned quality, use absolute ethanol as the ball milling medium, and ball mill for 16 hours to form a mixture, the particle size of the mixture is <10 μm; add 10wt% polyvinyl alcohol aqueous solution of the binder, mix evenly, and obtain a diameter of 2.5mm welding wire; argon arc welding is u...

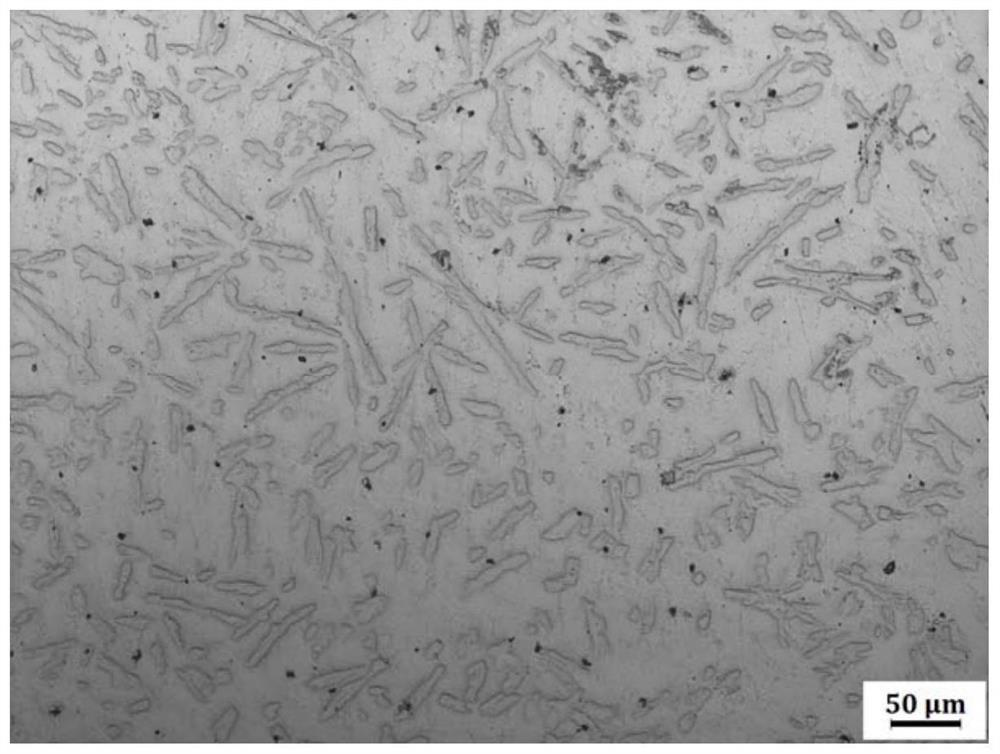

Embodiment 2

[0048] The present embodiment provides a kind of ternary boride, and its raw material comprises 195g iron boron powder, 625g ferromolybdenum powder, 130g chromium powder, 20g ferrosilicon powder, 20g nickel powder, 10g ferromanganese powder; Wherein, boron mass content is 3.66%, the mass content of silicon element is 1.18%, the mass content of iron element is 40.3%, the mass content of molybdenum element is 39.36%, the mass content of chromium element is 12.89%, the mass content of nickel element is 2%, the mass content of manganese element is 0.55% .

[0049] The preparation method of above-mentioned ternary boride comprises,

[0050] Weigh each raw material according to the above-mentioned quality, use absolute ethanol as the ball milling medium, and ball mill for 16 hours to form a mixture, the particle size of the mixture is <10 μm; add 10wt% polyvinyl alcohol aqueous solution of the binder, mix evenly, and obtain a diameter of 3.2mm welding wire; Plasma cladding is used ...

Embodiment 3

[0052] This embodiment provides a kind of ternary boride, and its raw material comprises 205g iron boron powder 18.79%, 496g ferromolybdenum powder 45.46%, 140g chromium powder 12.83%, 12g ferrosilicon powder 1.1%, 25g nickel powder 2.23%, 43g manganese Iron powder 3.94%, 50g molybdenum powder and 120g iron powder; wherein, the mass content of boron element is 3.53%, the mass content of silicon element is 0.71%, the mass content of iron element is 45.36%, the mass content of molybdenum element is 33.3%, the mass content of chromium element The content is 12.58%, the mass content of nickel element is 2.28%, and the mass content of manganese element is 2.18%.

[0053] The preparation method of above-mentioned ternary boride comprises,

[0054] Weigh each raw material according to the above-mentioned quality, use absolute ethanol as the ball milling medium, and ball mill for 16 hours to form a mixture, the particle size of the mixture is <10 μm; add 10wt% polyvinyl alcohol aqueou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com