Process device and process method of liquid phase reaction desulfurization of sulfur dioxide and hydrogen sulfide

A technology for sulfur dioxide and process equipment, which is applied in chemical instruments and methods, separation methods, and sulfur preparation/purification, etc., can solve the problems of increased operating costs of the equipment and the inability of the purity of sulfur products to meet market demand, etc., to prevent deposition and scaling, Increase the dissolution rate and reaction rate, the effect of easy reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

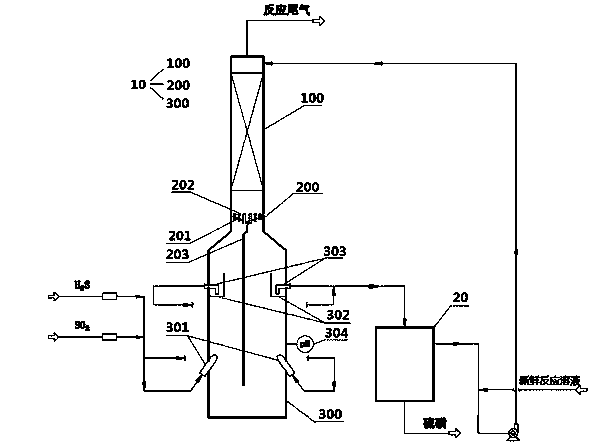

[0056] Sulfur dioxide and hydrogen sulfide liquid phase reaction desulfurization process equipment, such as figure 1 As shown, it includes a reactor 10 and a separator 20, and the reactor 10 is followed by a tail gas absorption zone 100, a liquid holding tank area 200 and a reaction zone 300 from top to bottom; the liquid holding tank area 200 includes a partition 201, Several lifters 202 and downcomers 203, the partitions 201 are fixed on the wall to isolate the tail gas absorption zone 200 from the reaction zone 300, the lifters 202 run through the partitions 201, and communicate with the tail gas absorption zone 100 and the reaction zone 300; one end of the downcomer 203 is fixed to the partition plate 201 and communicates with the tail gas absorption zone 100, and the other end extends downward to the bottom of the reaction zone 300; two nozzles 301 are arranged in the lower part of the reaction zone 300, symmetrically distributed, as The air inlet, the nozzle 301 is obliq...

Embodiment 2

[0059] use figure 1 The process device for sulfur dioxide and hydrogen sulfide reactive desulfurization process is as follows:

[0060] Pure SO 2 The gas is passed into the reaction zone 300 of the reactor 10 through two nozzles 301. The reaction solution in the reaction zone 300 is an aqueous solution of an organic basic compound. Pure H 2 S gas, the liquid in the reaction zone 300 quickly turns yellow, and it can be seen that the two react immediately to generate sulfur; the sulfur slurry flows upward into the liquid collection tank 302 under the impetus of the continuously fed gas, and is drawn out when the liquid level is higher than the liquid phase. At the outlet of the pipe 303, the sulfur-entrained slurry flows into the separator 20, the sulfur is separated from the reaction solution, and fresh reaction solution is added to the separated reaction solution, and after being pressurized by a pump, it is sent to the top of the tail gas absorption zone 100, and the reacti...

Embodiment 3

[0064] use figure 1 The process method for reactive desulfurization of sulfur dioxide and hydrogen sulfide in the shown device:

[0065] Except that the organic alkaline compound aqueous solution is 20% benzylamine solution, other conditions are the same as embodiment 2.

[0066] Access to H 2 The reaction response time of the two gases after S is 5s, calculated according to the material balance, H 2 The conversion rate of S was 93.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com