Itraconazole composite powder and preparation method thereof

A technology of itraconazole and composite powder, which is applied in the field of itraconazole composite powder and its preparation, can solve the problems affecting the clinical efficacy of drugs and poor dispersibility, and achieve excellent dissolution effect, simple process, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A: Weigh 0.35g of polyvinylpyrrolidone K30 and dissolve it in 20mL of deionized water. After it is completely dissolved, pour it into a stirring tank;

[0039] B: Weigh again 0.35g of itraconazole bulk drug and dissolve it in 10mL of tetrahydrofuran to obtain a solution of itraconazole bulk drug with a concentration of 3.5g / 100mL;

[0040] C: At a stirring speed of 1000rpm, quickly add the obtained raw drug solution into the stirring tank, so that the itraconazole drug is precipitated at 30°C, and stirred for 30 minutes to obtain a slurry of itraconazole drug particles;

[0041] D: Spray-dry the obtained slurry, select SD-Basic spray dryer, set the inlet temperature of the spray dryer to 140°C, the outlet temperature to 63°C-70°C, the feed rate to 20mL / min, and the pressure to 0.8MPa, Obtain dry itraconazole composite powder.

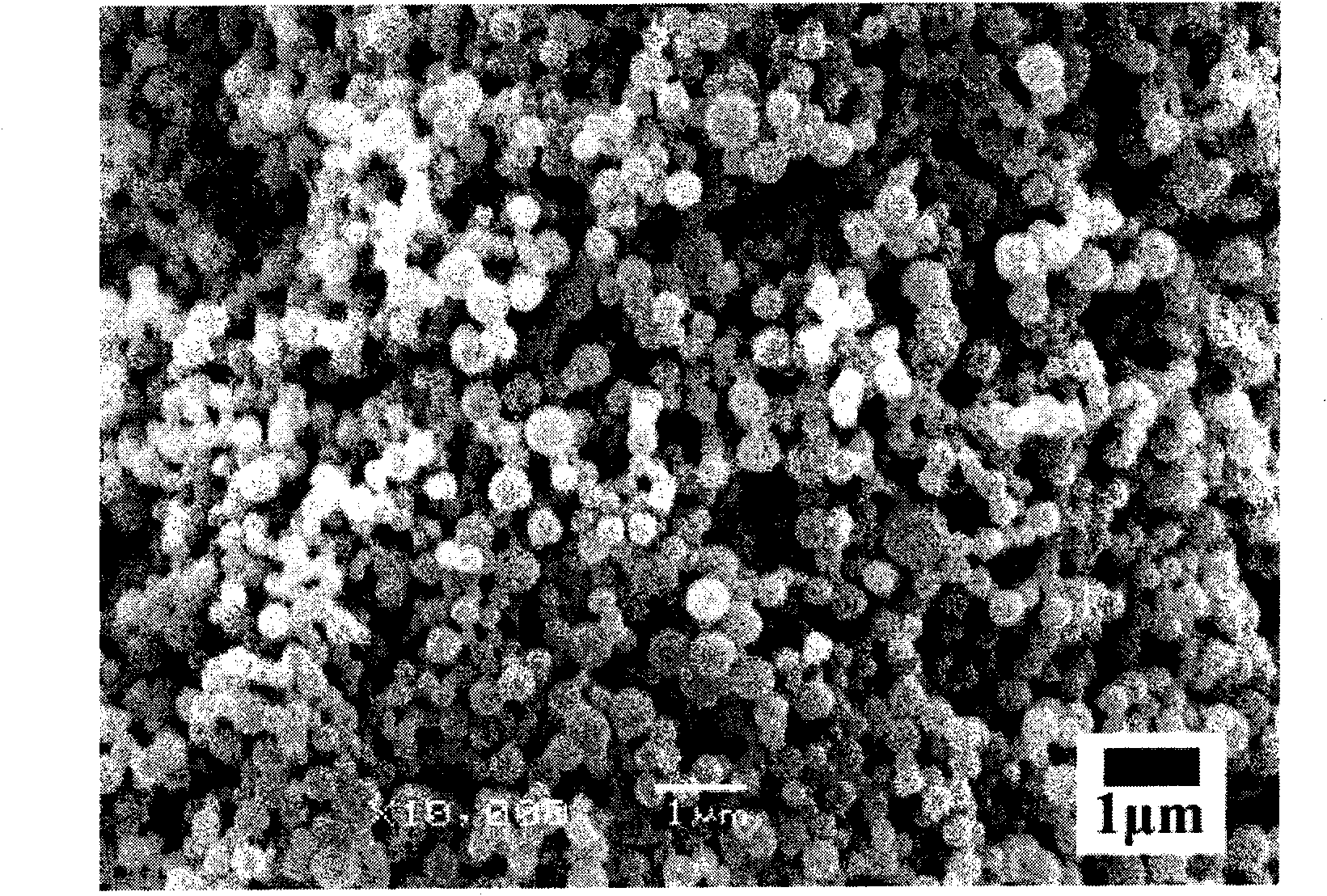

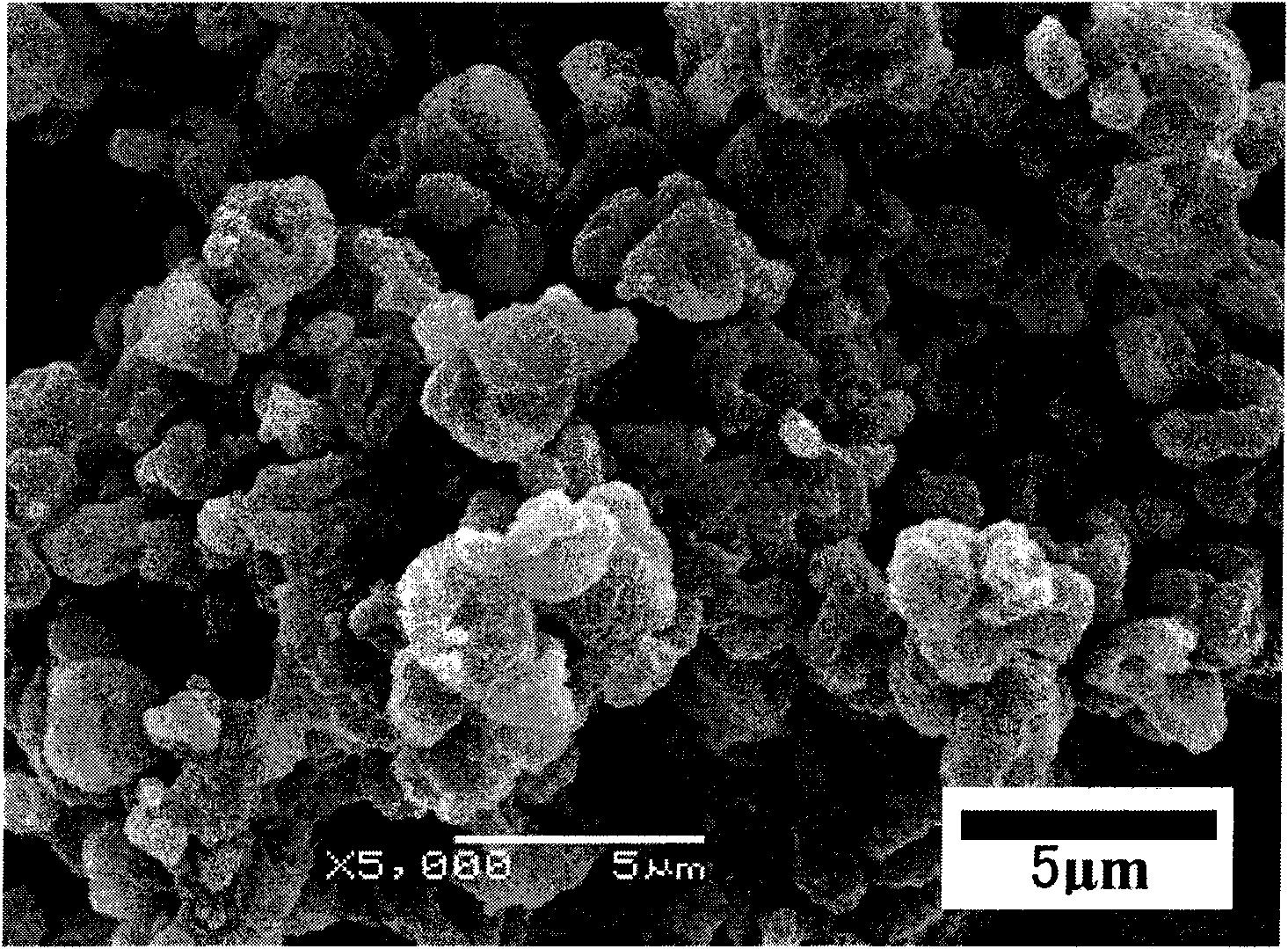

[0042] Observing with an electron scanning electron microscope, the particle size of the obtained composite powder is 0.5 μm to 15 μm, and the ...

Embodiment 2

[0044] A: Weigh 0.25g of hydroxypropyl methylcellulose and dissolve it in 250mL of deionized water. After it is completely dissolved, pour it into a stirring tank;

[0045]B: Take again 0.25g of itraconazole bulk drug and dissolve it in 25mL of nitrogen methyl pyrrolidone to obtain a solution of itraconazole bulk drug with a concentration of 1g / 100mL;

[0046] C: At a stirring speed of 800rpm, quickly add the obtained raw drug solution into the stirring tank, so that the itraconazole drug is precipitated at 20°C, and stirred for 20 minutes to obtain a slurry of itraconazole drug particles;

[0047] D: Spray-dry the obtained slurry, choose SD-Basic spray dryer, set the inlet temperature of the spray dryer to 100°C, the outlet temperature to 55°C-62°C, the feed rate to 10mL / min, and the pressure to 0.6MPa, Obtain dry itraconazole composite powder.

[0048] Observing with an electron scanning electron microscope, the particle size of the obtained composite powder is 1 μm to 10 μ...

Embodiment 3

[0050] A: Weigh 0.1g of hydroxypropyl methylcellulose and dissolve it in 144mL of deionized water. After it is completely dissolved, pour it into a stirring tank;

[0051] B: Weigh 0.1 g of itraconazole raw material drug and dissolve it in 7.2 mL of methanol / tetrahydrofuran co-solvent with a volume ratio of 1 / 1 to obtain a solution of itraconazole raw material drug with a concentration of 1.38 g / 100 mL;

[0052] C: At a stirring speed of 1000rpm, quickly add the obtained raw drug solution into the stirring tank, so that the itraconazole drug is precipitated at 15°C, and stirred for 10 minutes to obtain a slurry of itraconazole drug particles;

[0053] D: Pour the obtained slurry into liquid nitrogen, and use a CHRiST LT-105 freeze dryer to dry the ice cubes containing itraconazole drug particles to obtain dry itraconazole composite powder.

[0054] Observing with an electron scanning electron microscope, the particle size of the obtained composite powder is 0.5 μm to 1 μm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com