Wet-ground carbide-slag-containing activator and application

A calcium carbide slag and activator technology, applied in cement production and other directions, can solve the problems of difficulty in popularization and application and high activator cost, and achieve the effects of reducing energy consumption for preparation, improving resource utilization, and improving wet grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0022] The present invention will be described in detail below in conjunction with examples.

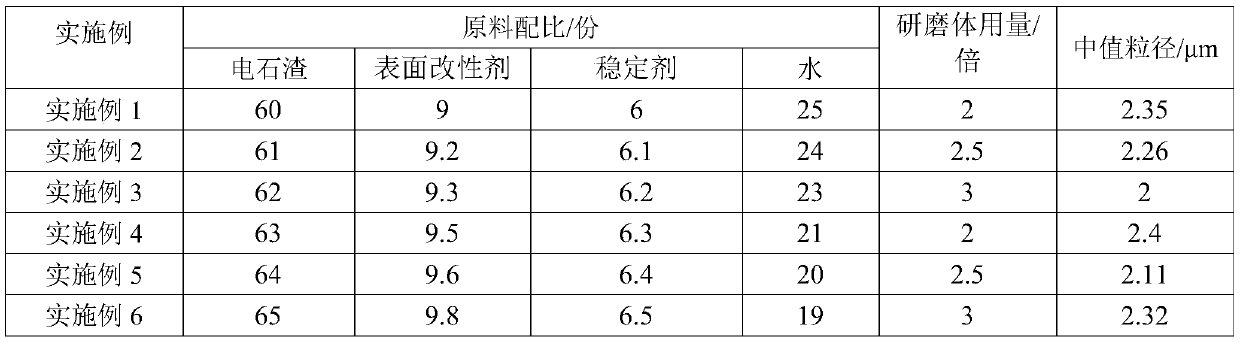

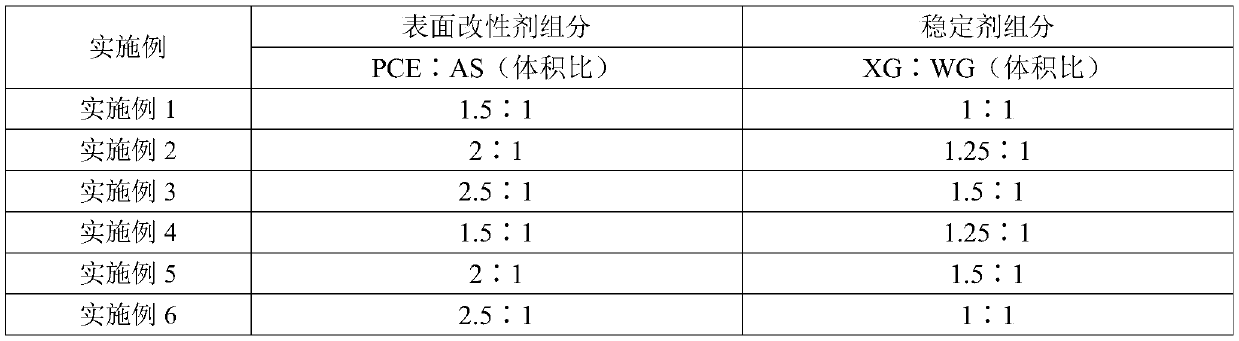

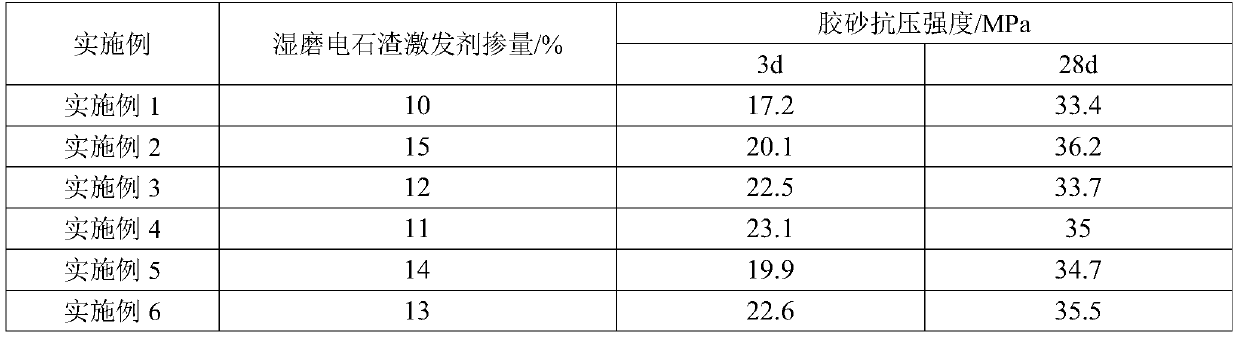

[0023] Table 1 shows the ratio of each component in the wet-grinding carbide slag activator of Examples 1 to 6 of the present invention and the fineness of the wet-grinding carbide slag activator of each example. Among them, Examples 1 to 6 of the present invention The calcium carbide slag in 6 is the waste residue with calcium hydroxide as the main component after the calcium hydroxide is hydrolyzed to obtain acetylene gas, and its calcium hydroxide content is 95%. It should be noted that the calcium hydroxide content of the calcium carbide slag in the present invention is not limited to 95%. %, as long as it is greater than 90%. Table 2 is the composition of surface modifier and stabilizer in the embodiment 1~em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com