Polyaluminocarbosilane with high aluminum content and low oxygen content, preparation method and SiAlC ceramic

A technology of polyaluminocarbosilane and low oxygen content, which is applied in the field of SiAlC ceramics and polyaluminocarbosilane preparation, can solve the problems of high preparation temperature, low oxygen content and complex reaction of polyaluminocarbosilane, and achieve excellent high temperature resistance and Antioxidant performance, improved preparation efficiency, simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] High-aluminum content of the present invention, the preparation method polyaluminocarbosilane low oxygen content, comprising the steps of:

[0036] Step 1: an inert gas atmosphere replaced Schlenk reaction vessel, particularly an inert gas is charged into the first reactor was evacuated, was repeated 3 to 5 times. Adding a certain amount of liquid hyperbranched polycarbosilanes, a certain proportion of methyl aluminoxane dissolved in an organic solvent and added dropwise to the reaction vessel and sufficiently stirred to obtain a homogeneous solution evenly; hyperbranched a liquid polycarbosilane with good flow properties, it is liquid at room temperature polycarbosilane;

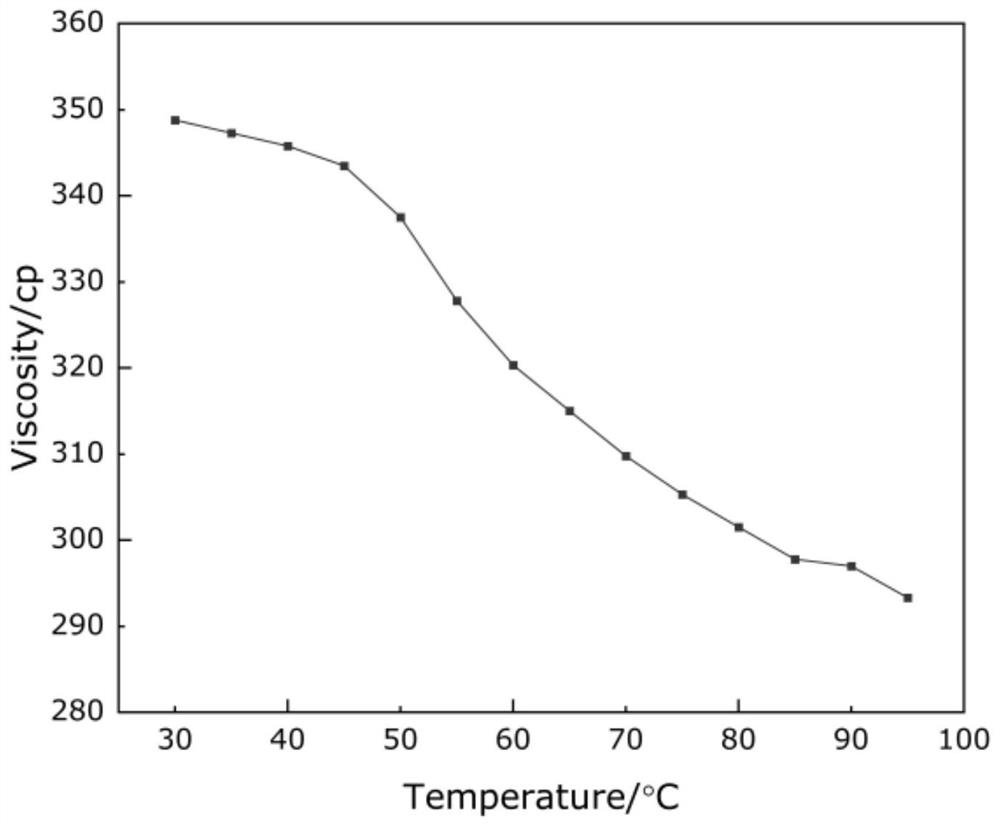

[0037] Step 2: the above-described homogeneous solution was heated reaction initiating system, to obtain a mixed system containing polyaluminum carbosilane. The reaction temperature is 50 ~ 90 ℃, the reaction time is 2 to 20 hours;

[0038] Step 3: After completion of the reaction system temperature is r...

Embodiment 1

[0045] 1) The air in the Schlenk reactor is replaced with an inert gas, specifically, the reactor is first vacuum, and the inert gas is filled into an inert gas and repeated 3 to 5 times. Ultra-branched liquid allylopolymetin silicone 30g (30 mmol) was added, and 32 g (55 mmol) was added to 25 mol / L methyl aluminoxane, and then added to the reactor, stirred slowly. After uniform, it gave a pale yellow homogeneous solution.

[0046] 2) The above-mentioned homogeneous solution was heated to 80 ° C and held for 6 h.

[0047] 3) After the reaction is completed, the system temperature is reduced to 30 ° C or less, and the vacuum pump is opened, and the solvent is removed, the distillation temperature is 60 ° C, the vacuum is -0.09 ~ -0.1MPa, until the system no longer has a solvent is essential The vacuum is stopped, and the temperature is lowered, and finally obtained light yellow liquid polyuminous carbonilane.

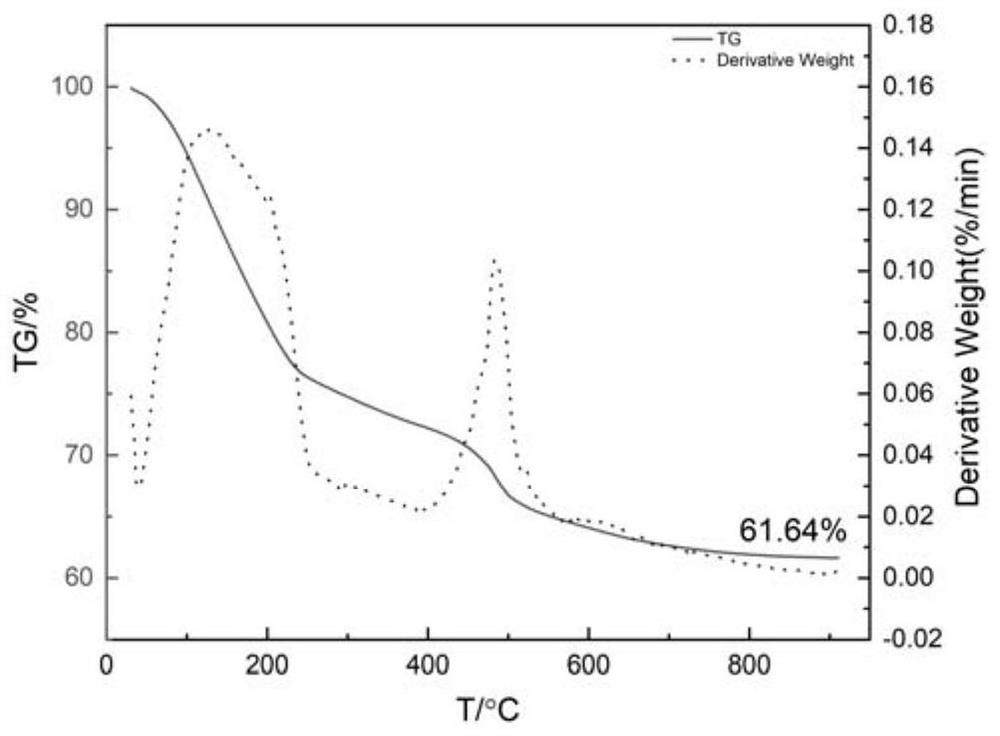

[0048] 4) Place the polyuminous carb silicone in the tube furnace, an...

Embodiment 2

[0051] 1) The air in the Schlenk reactor is replaced with an inert gas, specifically, the reactor is first vacuum, and the inert gas is filled into an inert gas and repeated 3 to 5 times. Ultra-bonded liquid allylopolymetin silicone 30g (30 mmol) was added, 10 g (17 mmol) toluene solution was taken at 25 mol / L methyl aluminoxane, slowly added to the reactor, stirring After uniform, it gave a pale yellow homogeneous solution.

[0052] 2) Heat the above-mentioned homogeneous solution to 70 ° C and heat it for 8 h.

[0053] 3) After the reaction is completed, the system temperature is reduced to 30 ° C or less, and the vacuum pump is opened, and the solvent is removed, the distillation temperature is 60 ° C, the vacuum is -0.09 ~ -0.1MPa, until the system no longer has a solvent is essential The vacuum is stopped, and the temperature is lowered, and finally obtained light yellow liquid polyuminous carbonilane.

[0054] 4) Place the polyuminous carb silicone in the tube furnace, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com