Hydrocracking catalyst and preparation method thereof, and hydrocracking reaction method

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as easy carbon deposition and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] According to a specific embodiment of the present invention, the MoY type zeolite molecular sieve is prepared according to a method comprising the following steps:

[0026] (1) mixing the Y-type zeolite molecular sieve with the Mo-containing compound to obtain a mixture of the Y-type zeolite molecular sieve and the Mo-containing compound;

[0027] (2) Roasting the mixture obtained in step (1) in an atmosphere containing water vapor to obtain MoY type zeolite molecular sieve;

[0028] Wherein, the MoY type zeolite molecular sieve is based on the dry basis, and the consumption of each component in the step (1) is such that in the final MoY type zeolite molecular sieve, the molybdenum content in terms of oxides is preferably 0.5-10% by weight , more preferably the molybdenum content in terms of oxide is 2-8% by weight. The molybdenum-containing compound is preferably selected from molybdenum oxides, chlorides or molybdates. The roasting conditions in the step (2) include...

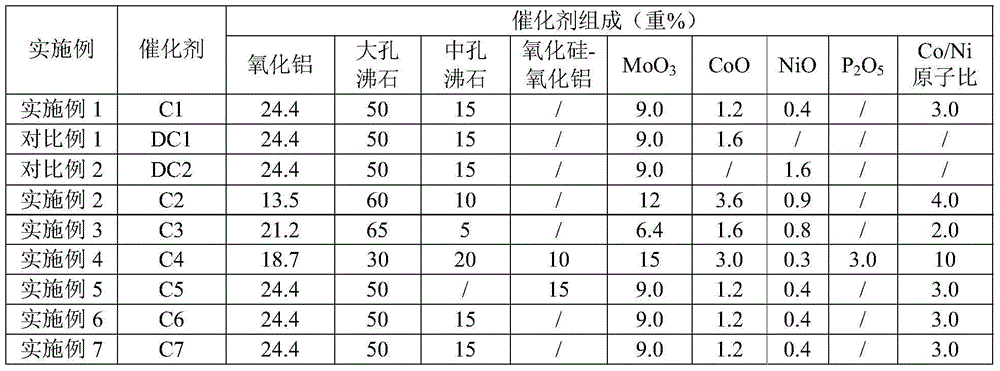

Embodiment 1

[0056] This example is used to illustrate the hydrocracking catalyst provided by the present invention and its preparation method.

[0057] 78.0 grams of dry basis is 70% pseudo-boehmite (Catalyst Changling Branch), 131.6 grams of dry basis is 76% HY type zeolite (Catalyst Changling Branch, unit cell constant is 24.62 Angstroms) and 36.6 The gram-dry basis is 82% ZSM-5 (silicon-aluminum ratio is 60:1) mixes evenly, extrudes on the extruder and is extruded into the trilobate bar shape that circumscribed circle diameter is 1.6 millimeters, is then dried at 120 ℃ for 3 hours, and then Calcined at 600° C. for 4 hours to obtain catalyst carrier Z1, whose composition is shown in Table 1.

[0058] 100 grams of the above carrier Z1 were mixed with 82 milliliters of ammonia solution containing ammonium molybdate, cobalt nitrate and nickel nitrate (converted into corresponding oxides containing 121.3 grams per liter of MoO 3 , 16.2 g / L CoO, 5.4 g / L NiO) impregnated for 1 hour, then dri...

Embodiment 2

[0066] This example is used to illustrate the hydrocracking catalyst provided by the present invention and its preparation method.

[0067] With 46.3 grams of dry basis is 70% pseudo-boehmite (Catalyst Changling branch), 191.7 grams of dry basis is 75% HY zeolite (catalyst Changling branch, unit cell constant is 24.59 Angstroms) and 29.8 grams The dry basis is 80% MCM-22 (silicon-aluminum molar ratio is 30:1) mixed evenly, extruded on extruder into a three-leaf strip shape with a circumscribed circle diameter of 1.6 mm, then dried at 120 ° C for 3 hours, and then Calcined at 580° C. for 3 hours to obtain catalyst carrier Z2, whose composition is shown in Table 1.

[0068] 100 grams of the above-mentioned carrier Z2 were mixed with 85 milliliters of ammonia solution containing ammonium molybdate, cobalt nitrate and nickel nitrate respectively (converted into corresponding oxides containing 169.1 grams per liter of MoO 3 , 50.7 g / L CoO, 12.7 g / L NiO) impregnated for 1 hour, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com