Hydrocracking catalyst and preparation method thereof, and hydrocracking reaction method

A hydrocracking and catalyst technology, which is applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as easy carbon deposition and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] According to a specific embodiment of the present invention, the Mo-Beta type zeolite molecular sieve is prepared according to the following method:

[0026] (1) Mixing Beta-type zeolite molecular sieve with Mo-containing compound to obtain a mixture of Beta-type zeolite molecular sieve and Mo-containing compound;

[0027] (2) Roasting the mixture obtained in step (1) in an atmosphere of water vapor to obtain Mo-Beta type zeolite molecular sieve;

[0028] Wherein, based on the Mo-Beta type zeolite molecular sieve on a dry basis, the amount of each component in the step (1) is such that the molybdenum content in the final Mo-Beta type zeolite molecular sieve is preferably 0.5 -10% by weight, more preferably, the content of molybdenum in terms of oxide is 1-6% by weight; the molybdenum-containing compound is preferably selected from molybdenum oxides, chlorides, or molybdates. The roasting conditions in the step (2) include: the temperature is 200-700°C, preferably 400-650°C; t...

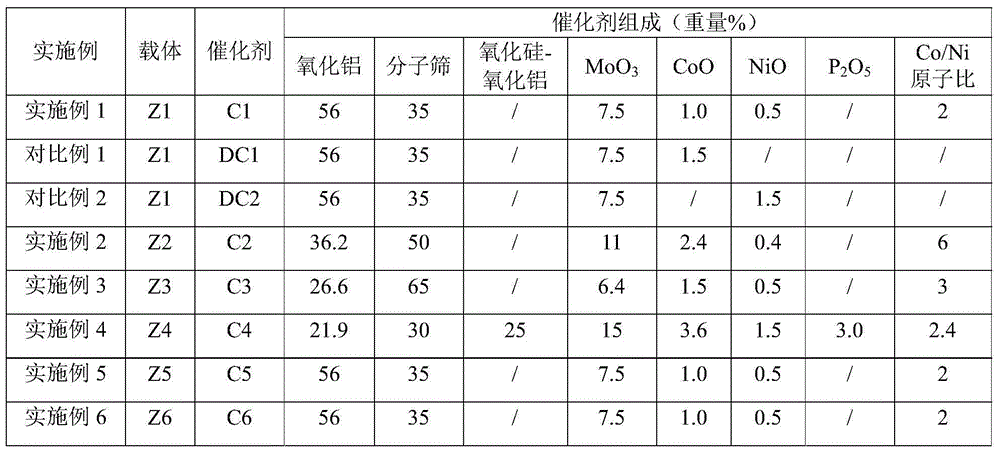

Embodiment 1

[0055] This example is used to illustrate the hydrocracking catalyst provided by the present invention and its preparation method.

[0056] Combine 175.7 grams of pseudo-boehmite with a dry basis of 70% (Catalyst Changling Branch) and 95.06 grams of β-zeolite molecular sieve with a dry basis of 81% (Product of the Catalyst Changling Branch, with a silicon-aluminum molar ratio of 25) The mixture was uniformly mixed and extruded into a three-lobed strip with a circumscribed circle diameter of 1.6 mm on an extruder, then dried at 120°C for 3 hours, and then calcined at 600°C for 4 hours to obtain a catalyst carrier Z1, whose composition is shown in Table 1.

[0057] Use 100 g of the above carrier Z1 with 75 ml of ammonia solution containing ammonium molybdate, cobalt nitrate and nickel nitrate (converted to the corresponding oxides containing 109.9 g / L MoO 3 , 14.7 g / L CoO, 0.73 g / L NiO) was impregnated for 1 hour, and then the impregnated support was dried at 120°C for 2 hours, and th...

Embodiment 2

[0065] This example is used to illustrate the hydrocracking catalyst provided by the present invention and its preparation method.

[0066] Combine 120 grams of pseudo-boehmite with a dry basis of 70% (Catalyst Changling Branch) and 145 grams of zeolite β molecular sieve with a dry basis of 80% (Product of the Catalyst Changling Branch, the molar ratio of silicon to aluminum is 24.5) The mixture was uniformly mixed and extruded into a trilobal strip with a circumscribed circle diameter of 1.6 mm on an extruder, then dried at 120°C for 3 hours, and then calcined at 580°C for 3 hours to obtain a catalyst carrier Z2. The composition is shown in Table 1.

[0067] Take 100 g of the above carrier Z2 with 85 ml of ammonia solution containing ammonium molybdate, cobalt nitrate and nickel nitrate (converted into corresponding oxides containing 156 g / L MoO 3 , 34 g / L CoO, 5.7 g / L NiO) was impregnated for 1 hour, and then the impregnated support was dried at 120°C for 2 hours, and then calcine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com