Pretreatment method for producing needle coke raw material

A needle coke raw material and pretreatment technology, which is applied in the treatment of hydrocarbon oil, hydrotreating process, petroleum industry, etc., can solve the problems of non-uniformity, large influence of needle coke morphology and thermal expansion coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

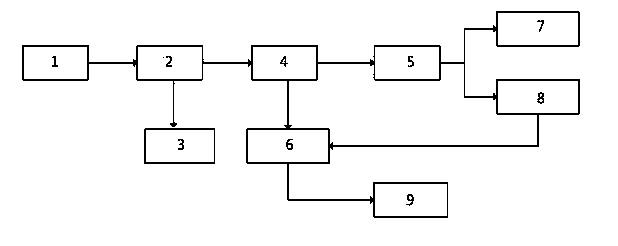

Method used

Image

Examples

Embodiment 1

[0022] Utilize the method of the present invention to process the catalytic oil slurry of a refinery in China as shown in Table 1. The oil slurry is first filtered and pretreated. Hydrogen treatment device, the active components of the hydrogenation catalyst are Ni and W. The hydrogenation reaction temperature is 380°C, the reaction hydrogen partial pressure is 3.0MPa, and the hydrogen-to-oil ratio is 200 Nm 3 / m 3 , the volume space velocity is 0.8h -1 , 30 (w)% of the hydrogenated oil is sent to the vacuum distillation device, the pressure of the vacuum distillation is 20mmHg, and the temperature is 400°C. After passing through the vacuum distillation device, the separated light distillate oil and the remaining 70 (w) The final high-quality needle coke raw material is obtained after the hydrogenated oil is mixed. The properties of the final high-quality needle coke raw materials are shown in Table 2. figure 1 It is the needle coke fiber structure observed under the scann...

Embodiment 2

[0024] Utilize the method of the present invention to process the catalytic oil slurry of a domestic refinery as shown in Table 1. The oil slurry is first filtered and pretreated. Hydrogen treatment device, the active components of the hydrogenation catalyst are Ni and W. The hydrogenation reaction temperature is 350°C, the reaction hydrogen partial pressure is 2.5MPa, and the hydrogen-to-oil ratio is 300 Nm 3 / m 3 , the volumetric space velocity is 2.5h -1 , 40 (w)% of the hydrogenated oil is sent to the vacuum distillation device, the pressure of the vacuum distillation is 60mmHg, and the temperature is 350°C. After passing through the vacuum distillation device, the separated light distillate oil and the remaining 60 (w) The final high-quality needle coke raw material is obtained after the hydrogenated oil is mixed. The properties of the final high-quality needle coke raw materials are shown in Table 2. image 3 It is the needle coke fiber structure observed under the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com