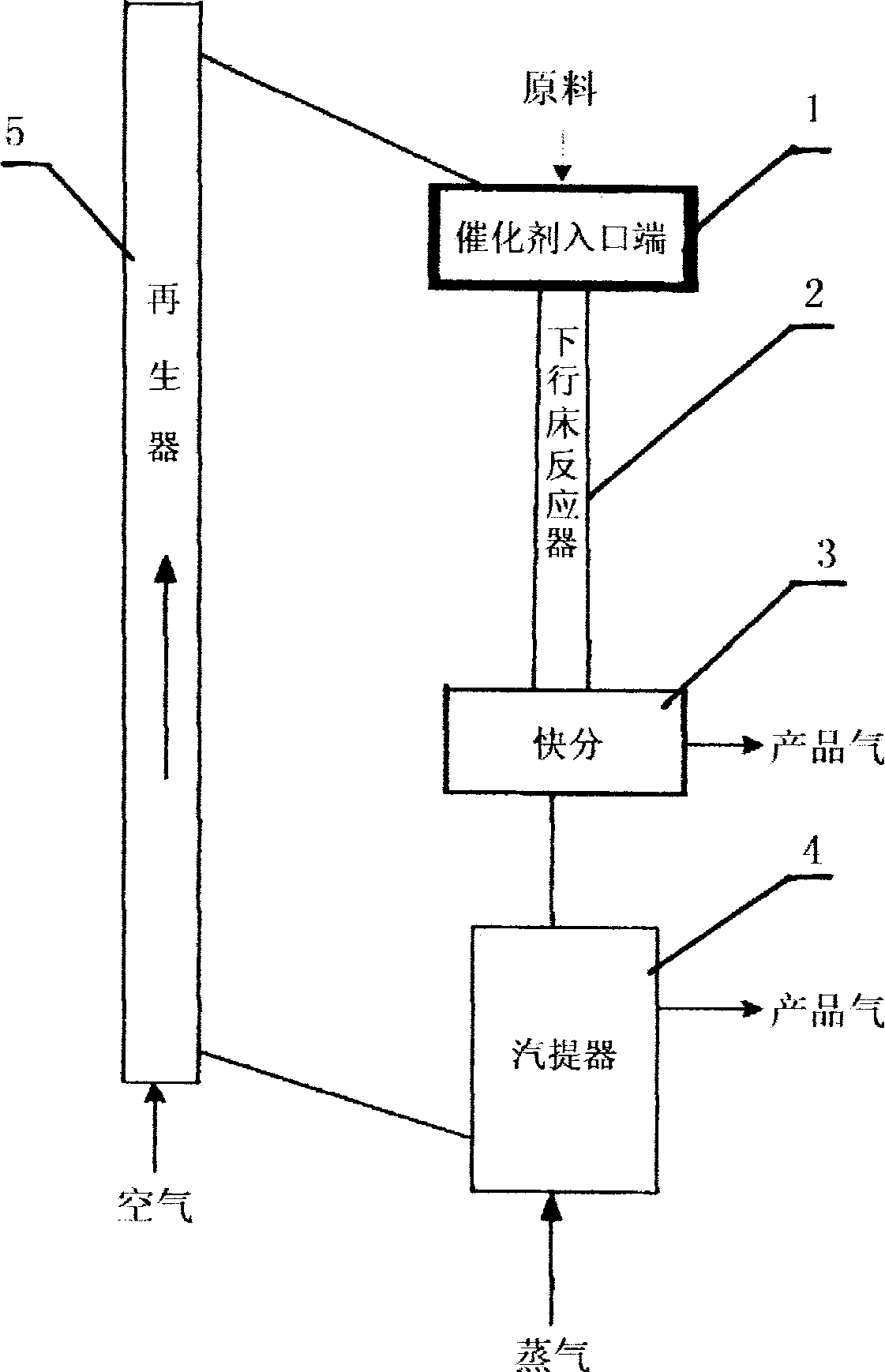

Process for catalytic thermocracking of bydrocarbon by descending-bed reactor

A catalytic thermal cracking, bed reactor technology, applied in the field of fractional distillation and cracking of petroleum products, can solve the problems of long gas-solid contact time, radial non-uniformity, impact on economy and application, high olefin content, etc., and achieve increased stability , Low production cost, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The invention is a method for catalytic thermal cracking of hydrocarbons by using a down-bed reactor. That is, when the catalytic thermal cracking process is carried out in the down-bed reactor, the raw material oil and catalyst enter the reactor through the catalyst inlet section, realize uniform distribution on its cross section, and enter the oil agent mixing area, and the raw material oil depends on the action of steam at the same time Realize atomization, and quickly contact and mix with the high-temperature catalyst, the gas-solid mixture flows downward, and the cracking reaction occurs at the same time, generating high-temperature oil and gas including a wide-boiling hydrocarbon mixture; the catalyst loses catalytic activity due to coke deposition on it, after regeneration Reuse; the gas-solid mixture of high-temperature oil and gas stays in the reactor for a short time, and is quickly separated by the gas-solid rapid separation device at the end of the down-bed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com