Environmental-friendly rubber filling oil and preparation method thereof

An environmentally friendly rubber and oil filling technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

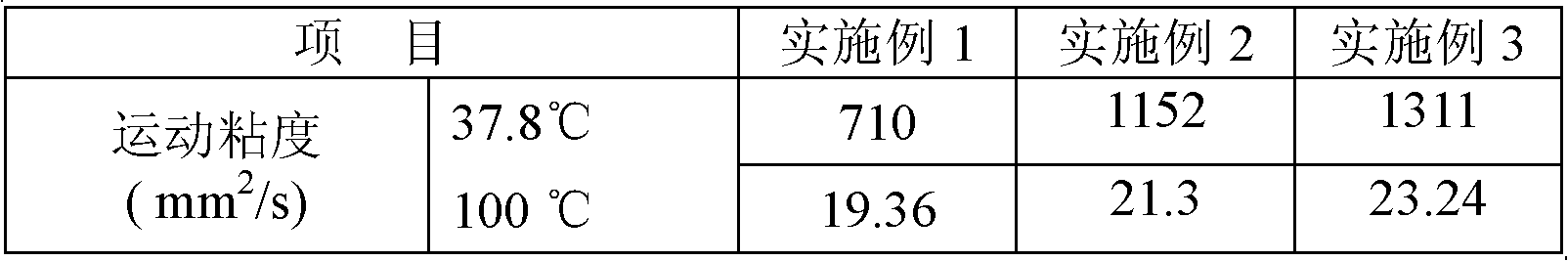

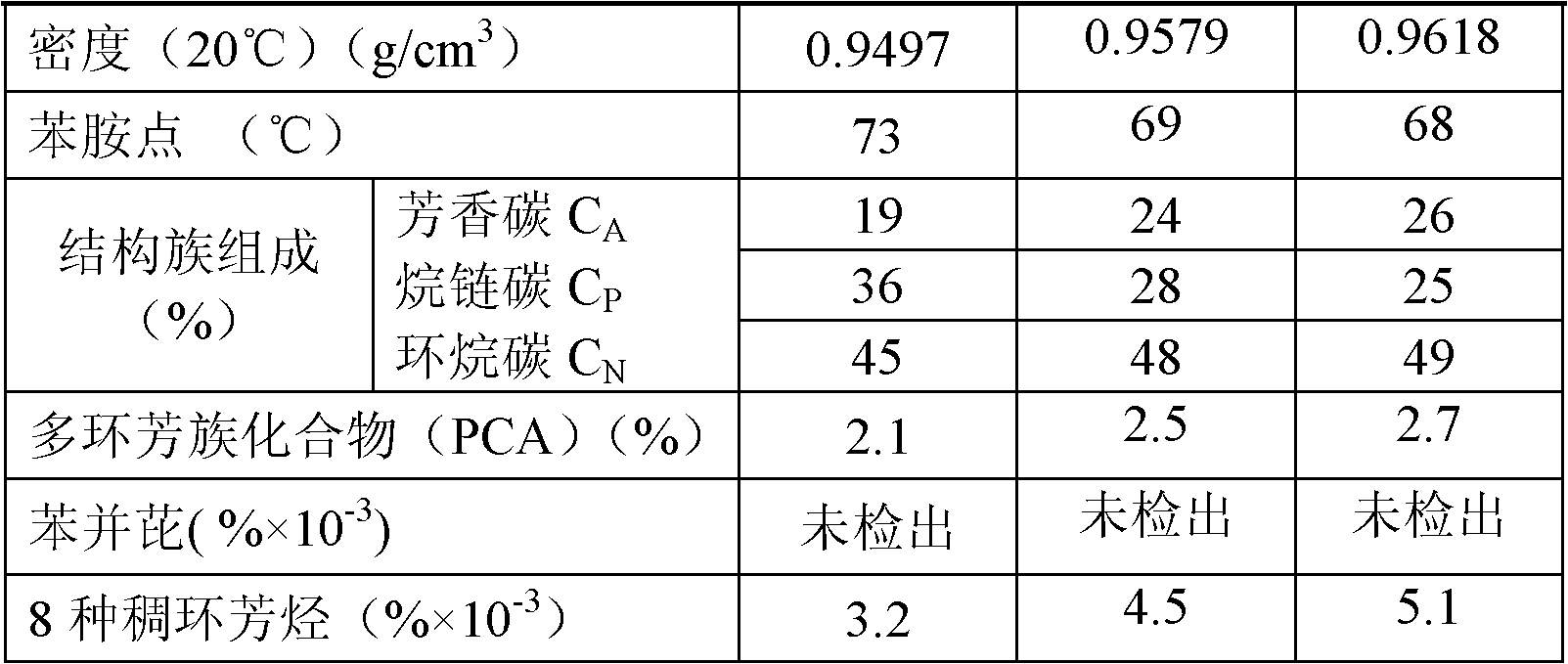

Embodiment 1

[0019] Example 1. Preparation of environmentally friendly rubber filling oil

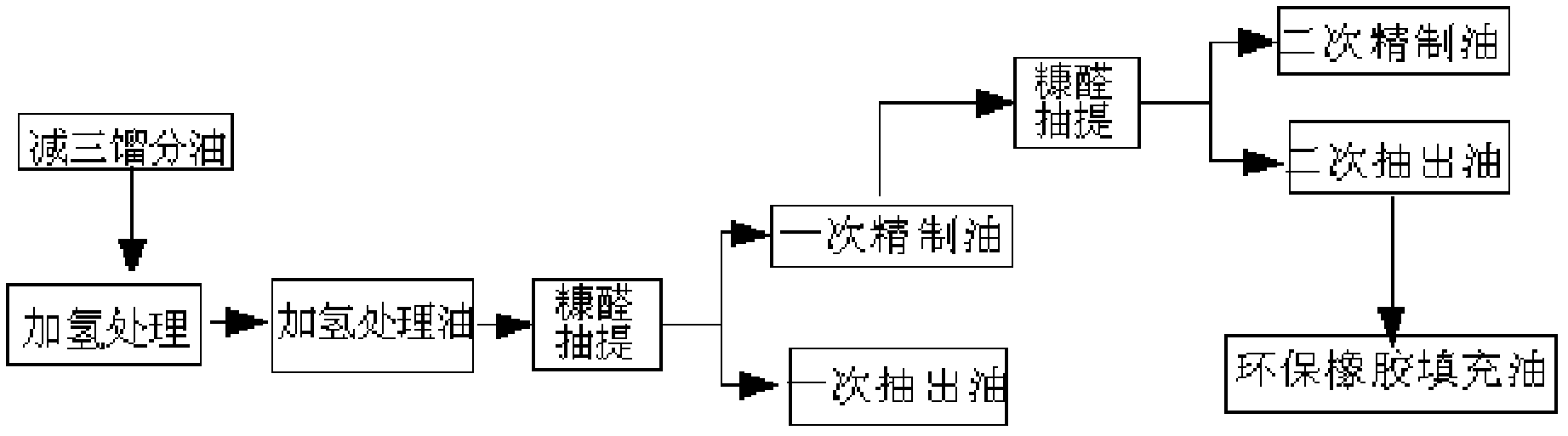

[0020] The preparation process is like figure 1 The flowchart shown.

[0021] (1) Using Zhonghai SZ36-1 minus third-line distillate (China Overseas Asphalt Co., Ltd., product name SZ3#, see: http: / / www.zhonghaibitumen.com) as raw material, and hydrogenating through a low-pressure hydrorefining unit Process to obtain hydrotreated oil; hydrogenation conditions are: hydrogen partial pressure 6.4Mpa, reaction temperature 280℃, volumetric space velocity 2.0h -1 , The ratio of hydrogen to oil is 600:1, and the hydroprocessing catalyst is RL-1 type lubricating oil hydroprocessing catalyst (Sinopec Changling Refining & Chemical Co., Ltd.);

[0022] 2) Using the hydrotreated oil obtained above as the raw material, extract with furfural in the extraction tower, get the raffinate at the top of the tower, and get the extract at the bottom of the tower; after the raffinate removes furfural, it becomes the primary refi...

Embodiment 2

[0025] Example 2. Preparation of environmentally friendly rubber filling oil

[0026] The preparation process is like figure 1 The flowchart shown.

[0027] (1) Using Zhonghai SZ36-1 minus third-line distillate (China Overseas Asphalt Co., Ltd., product name SZ3#, see: http: / / www.zhonghaibitumen.com) as raw material, and hydrogenating through a low-pressure hydrorefining unit Process to obtain hydrotreated oil; hydrogenation conditions are: hydrogen partial pressure 3.2Mpa, reaction temperature 310℃, volumetric space velocity 1.5h -1 , The ratio of hydrogen to oil is 400:1, and the hydroprocessing catalyst is RL-1 type lubricating oil hydroprocessing catalyst (Sinopec Changling Refining & Chemical Co., Ltd.);

[0028] (2) Using the hydrotreated oil obtained above as the raw material, the extraction is carried out in the extraction tower, the raffinate is obtained at the top of the tower, and the extract is obtained at the bottom of the tower; after the furfural is removed from the r...

Embodiment 3

[0031] Example 3. Preparation of environmentally friendly rubber filling oil

[0032] The preparation process is like figure 1 The flowchart shown.

[0033] (1) Using Zhonghai SZ36-1 minus third-line distillate (China Overseas Asphalt Co., Ltd., product name SZ3#, see: http: / / www.zhonghaibitumen.com) as raw material, and hydrogenating through a low-pressure hydrorefining unit Process to obtain hydrotreated oil; the hydrogenation conditions are: hydrogen partial pressure 6.4Mpa, reaction temperature 330℃, volumetric space velocity 0.8h -1 , Hydrogen to oil ratio is 200:1, and the hydroprocessing catalyst is RL-1 type lubricating oil hydroprocessing catalyst (Sinopec Changling Refining & Chemical Co., Ltd.);

[0034] 2) Using the above-mentioned hydrotreated oil as the raw material, extract in the extraction tower, get the raffinate at the top of the tower, and get the extract at the bottom of the tower; after the raffinate is removed the furfural, it is the primary refined oil, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| aniline point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com