Method for preparing lubricating oil base oil

A technology for lubricating base oils and hydrocarbon oils, applied in the petroleum industry, processing hydrocarbon oils, and hydrotreating processes, etc., can solve problems such as poor hydrodearomatization effects, and achieve low pour point, improved effects, and high yields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The silica-alumina can be prepared by uniformly mixing alumina hydrate with at least one disordered silicon-containing molecular sieve or a composition containing a disordered silicon-containing molecular sieve at 350-850°C, preferably Roasting at 450-650° C. for 2-8 hours, preferably 3-6 hours; it can also be: aluminum oxide of one or more crystal forms selected from γ, η, θ, δ and χ and at least one The disordered silicon-containing molecular sieve or the composition containing the disordered silicon-containing molecular sieve is directly mixed uniformly.

[0013] Wherein, the alumina hydrate is selected from one or more mixtures of trihydrated alumina, monohydrated alumina and amorphous aluminum hydroxide. Said aluminum oxide hydrate can also be a modified product of the hydrate, such as a modified product added with silicon, titanium, magnesium, boron, zirconium, thorium, niobium, rare earth, etc., wherein the modified product of silicon is preferred, They can be p...

Embodiment 1

[0058] This example takes a kind of waxy lubricating oil distillate oil as raw material, and its properties are shown in Table 1.

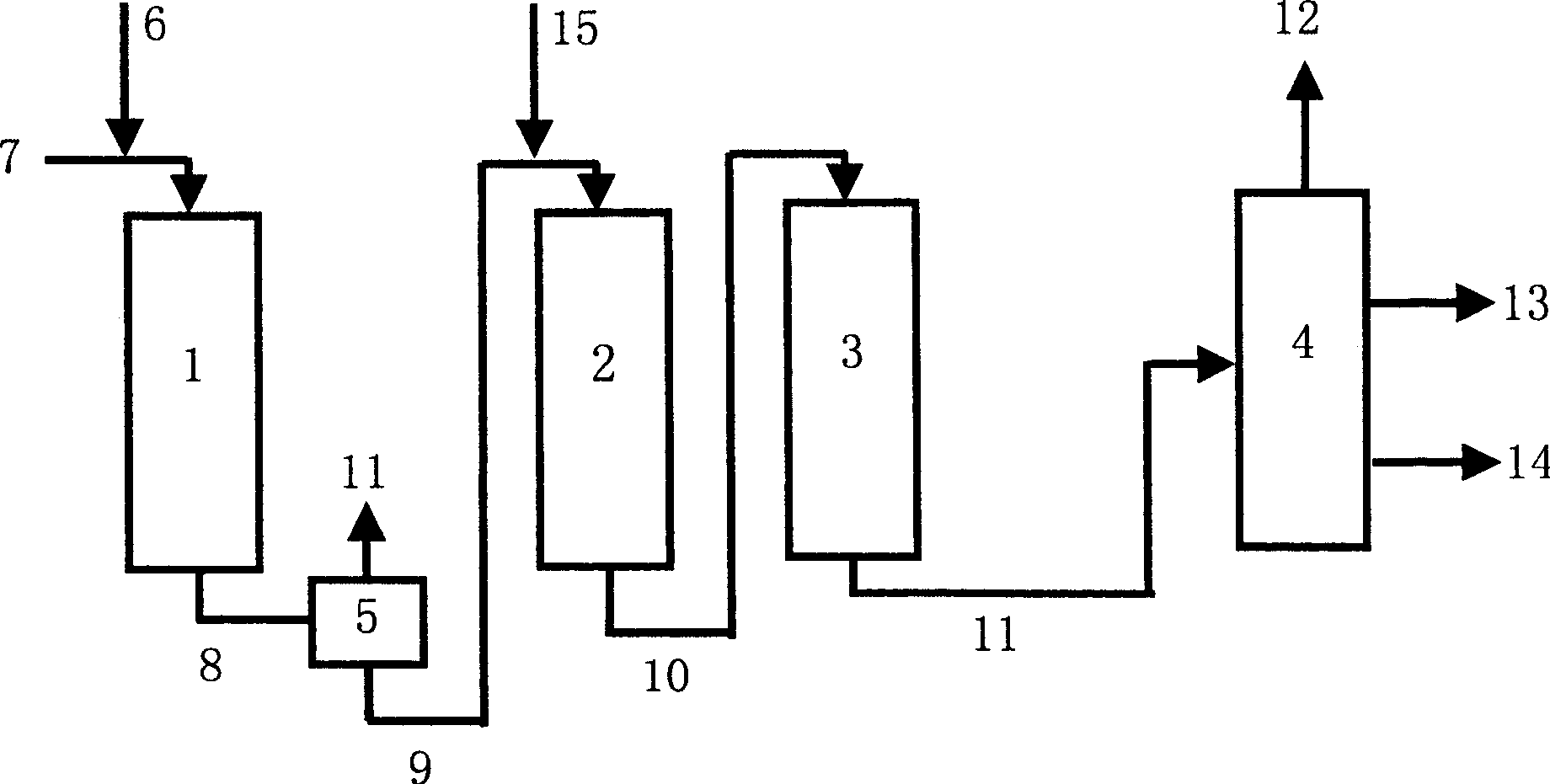

[0059] according to figure 1 The process flow processes the raw oil. The catalysts are: hydrotreating catalyst a, dewaxing catalyst b, hydrogenation catalyst b, the operating conditions are shown in Table 2, and the properties of the formed oil are shown in Table 3.

[0060] Raw oil

[0061] Process conditions

[0062] base oil yield

Embodiment 2

[0068] This example takes a kind of naphthenic lubricating oil distillate as raw material, and its properties are shown in Table 6.

[0069] according to figure 1 The process flow processes the raw oil. The catalysts are: hydrotreating catalyst a, dewaxing catalyst a, hydrogenation catalyst a, see Table 7 for the operating conditions, and see Table 8 for the properties of the resulting oil.

[0070] Raw oil

[0071] Process conditions

[0072] Base oil yield m%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com