Resin impregnated substrate, method of mfg. and system therefor

A substrate, resin material technology, applied in the direction of polymer impregnation, transportation and packaging, other household appliances, etc., can solve the problems of high texture, roughness, and unsightly appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

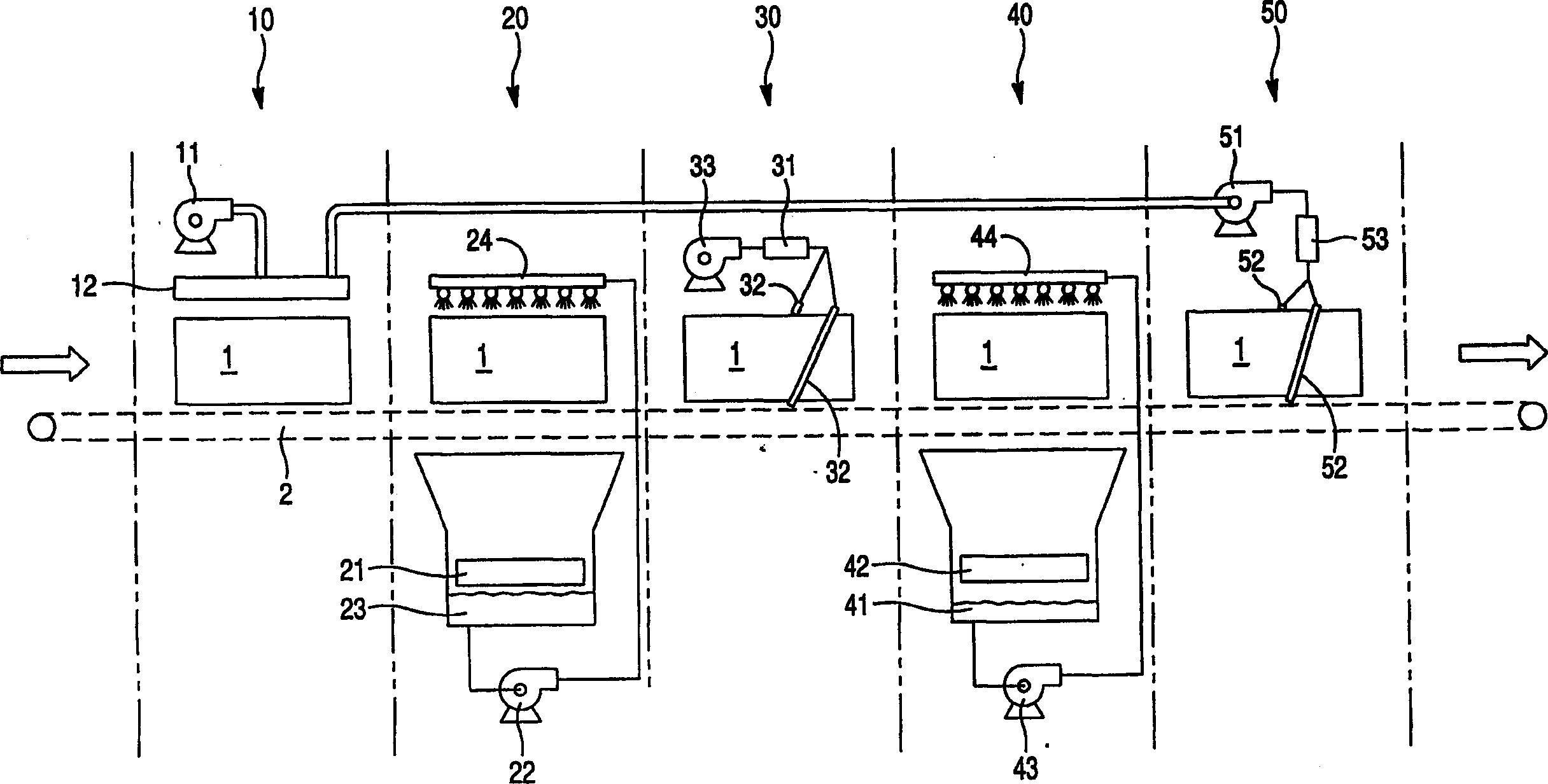

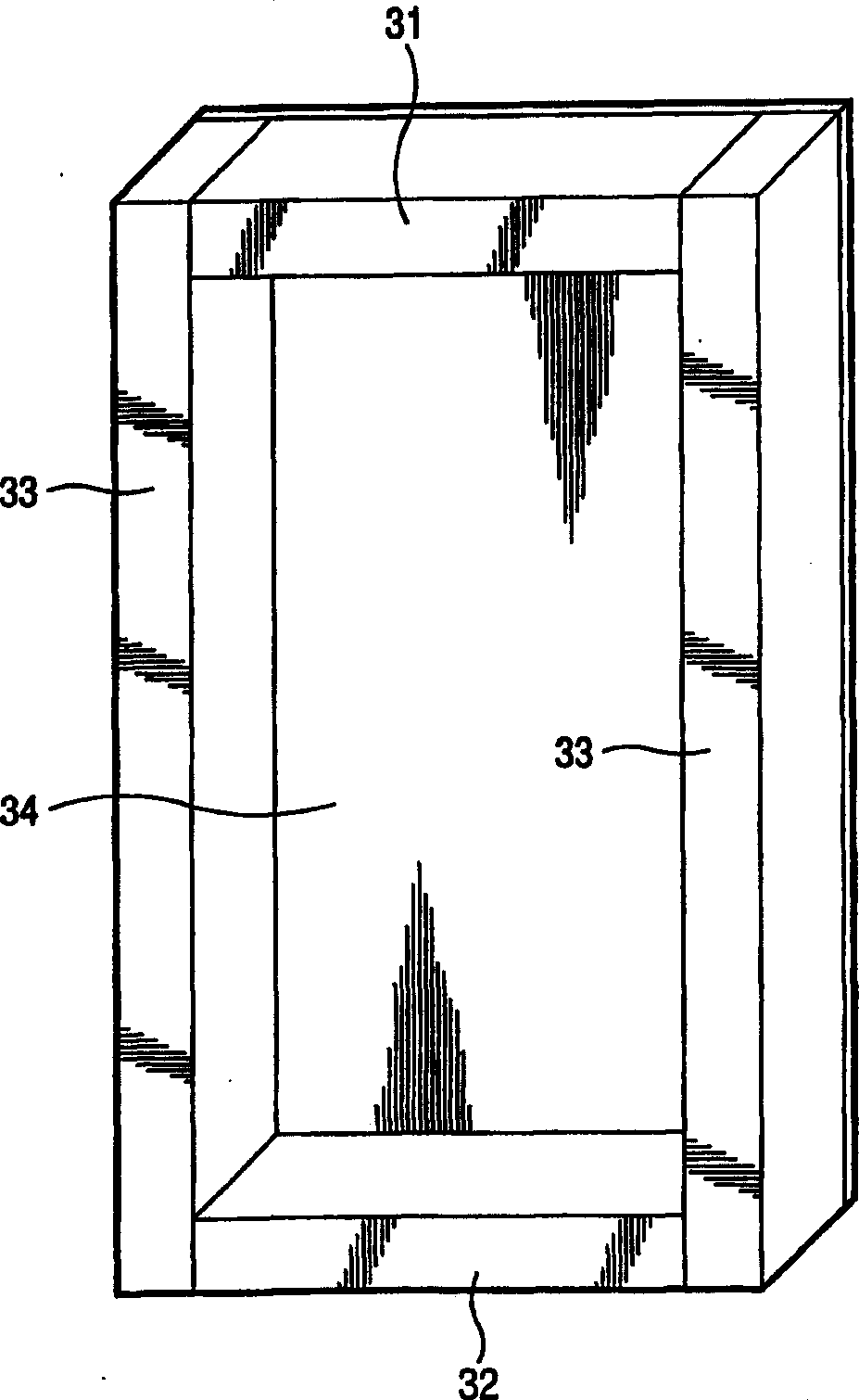

Method used

Image

Examples

Embodiment

[0054] The performance of six different PMDI styles was compared by treating door skins and door rails / sides with PMDI. These PMDI-style trademarks are as follows: 1) Lupranate M20S (BASF); 2) Elastocast 7034U (BASF); 3) WUC 3092 T (BASF); 4) Desmodur VKS-18 (Bayer); 5) E-743 (Bayer); 6) X0672 (Bayer).

[0055] Each formula is a mixture of 33-49% methylene diphenyl-4,4'-diisocyanate, 3 (25°C), density 9.0-10.3lbs / gal, viscosity 200-3300 centipoise (25°C), NCO content 23-31.5wt%, functionality 2.7.

[0056] Treat the door skin and door rail / edge material as follows.

[0057] The door rail / jar material is 1" thick, 44 lb MDF from Temple. Test samples designated "B" were cut into pieces 6 inches long by 1 1 / 2 inches wide. A test sample designated "A" was shaped to fit a metal door and then cut into 6-inch lengths. The cross-section of Sample "A" was 7 / 8 inches by 1 5 / 8 inches. Drill a 0.120" diameter pilot hole through each piece of door rail / sill material. It is not possib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com