A kind of processing and preservation method of mud cockles in sauce

A technology of sauce and mud clams, applied in food preservation, meat/fish preservation, preservation of meat/fish by radiation/electrical treatment, etc., can solve the probability of secondary pollution and reproduction of microorganisms, increase the hidden danger of food safety, and have a long production cycle. and other problems, to achieve the effect of reducing the probability of microbial contamination and reproduction, improving taste and safety quality, and improving hygiene, quality and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

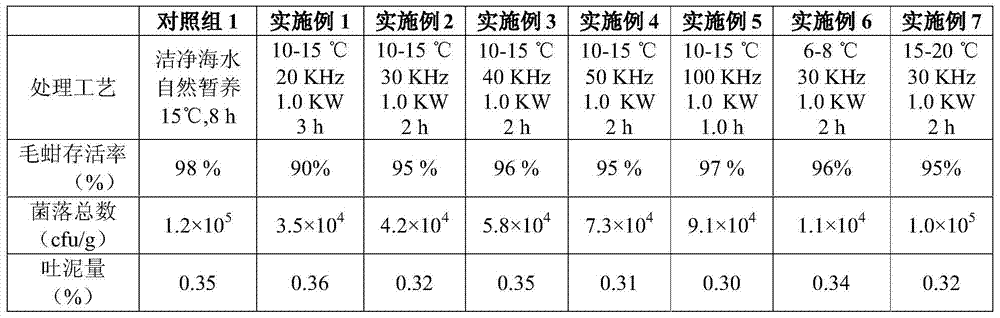

[0022] Embodiments 1-7 Influence of Ultrasonic Frequency on Purification Process

[0023] Newly caught cockles generally carry more bacteria, and need to be stocked and purified in clean seawater for 8 to 72 hours, so that the cockles can spit out the sediment and most of the pollutants. The effects of different ultrasonic treatments on the hygienic quality of cockle purification are shown in Table 1:

[0024] Table 1

[0025]

[0026] After 8 hours of natural purification, the total number of original colonies of mud cockles increased from 4.2×10 6 down to 1.2×10 5 . Ultrasonic treatment with different intensities can reduce the number of bacteria in cockles to 1.1×10 4 ~9.1×10 4 , which should be derived from the cavitation effect of ultrasonic waves. Comparing the data in Table 1, it can be seen that low-frequency sound wave treatment is also beneficial for stimulating mud cockles to spit mud, and the suitable ultrasonic frequency is 30KHz; low temperature is benef...

Embodiment 8~12

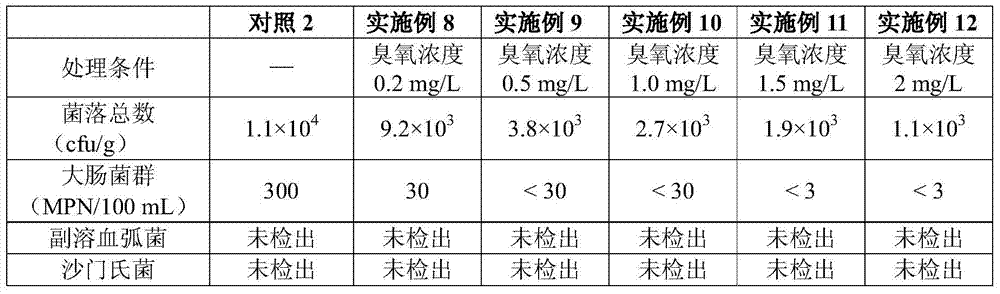

[0028] Examples 8-12 Research on the Effect of Ozone Water Bacteria Reduction Treatment

[0029] After ultrasonic-assisted clean seawater purification treatment, the sediment of the cockles was basically discharged, and the amount of bacteria was significantly reduced. However, in order to reduce the intensity of subsequent electron beam sterilization, improve product sensory and nutritional quality, and extend shelf life, it is necessary to take bacteria reduction treatment to further reduce the total number of bacterial colonies in the product, kill pathogenic bacteria, and ensure product quality and safety.

[0030] In Example 6, the cockles treated with preliminary ultrasonic-assisted purification were centrifuged and drained, then added to ozone water of different concentrations 5 to 10 times their own weight, and soaked for 20 minutes. The bacteria-reducing effect of ozone is shown in Table 2.

[0031] Table 2

[0032]

Embodiment 13~16

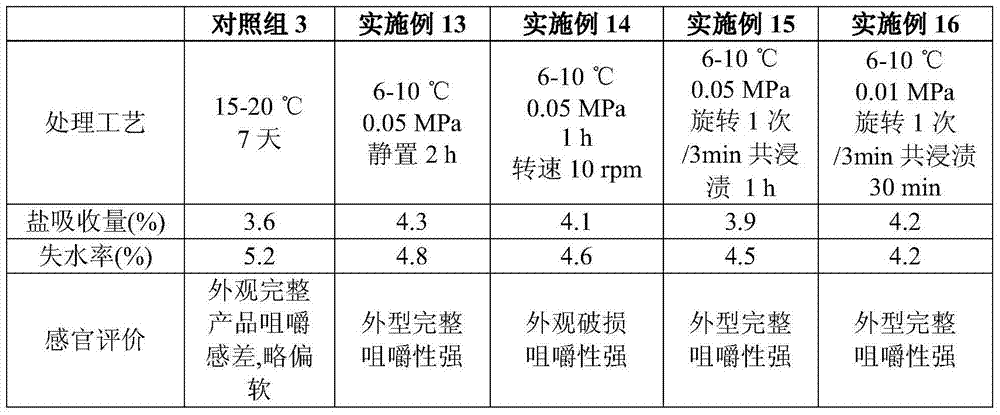

[0034] Examples 13-16 Research on the Effect of Vacuum Negative Pressure Impregnation Treatment

[0035] The cockles after purification and bacteria reduction treatment were treated with vacuum negative pressure impregnation, and the traditional natural soaking and pickling (7 days) was used as a control. The specific impregnation effects are shown in Table 3.

[0036] The pickling liquid is mixed with the following raw materials: 60% white wine, 14% soy sauce, 1.5% white sugar, 4.0% table salt, 0.5% monosodium glutamate, and 20% purified water.

[0037] table 3

[0038]

[0039] The most significant advantage of vacuum negative pressure impregnation is to significantly shorten the impregnation time. Due to the high content of collagen connective tissue on the surface of cockles, the pickling solution is not easy to penetrate, so it usually takes 2-7 days to soak thoroughly. Pickling for a long time will increase the chance of bacterial contamination and the breeding and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com