Preparation method of rehydrated walnut kernels capable of being stored at normal temperature

A technology of normal temperature preservation and walnut kernel, applied in the direction of food preservation, heat preservation of seeds, edible seeds preservation, etc., can solve the problems of spoilage, short sales radius, short shelf life, etc., to reduce the degree of product deterioration, avoid The effect of protein denaturation and crisp taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

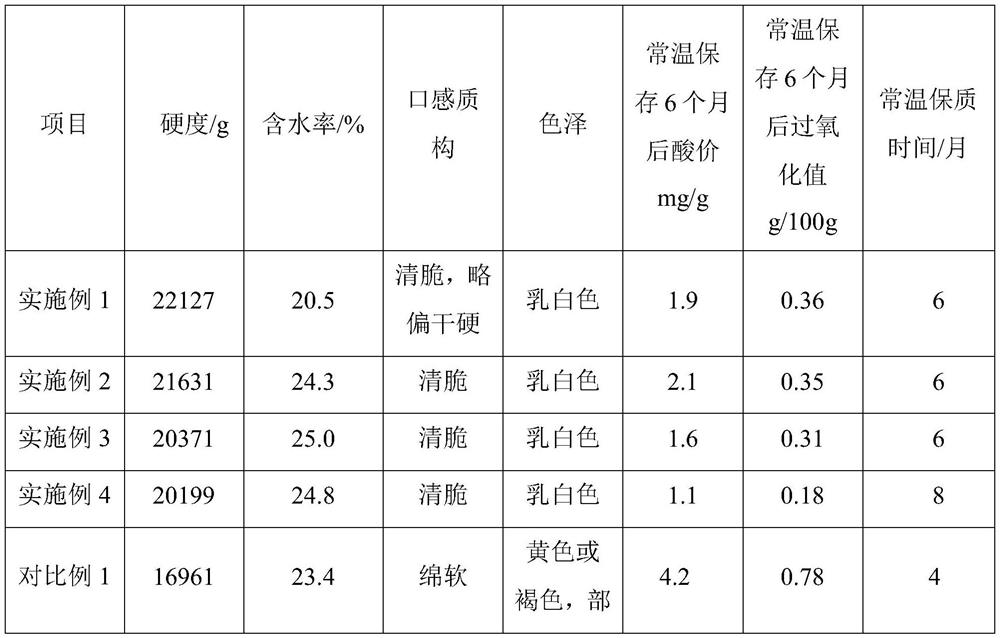

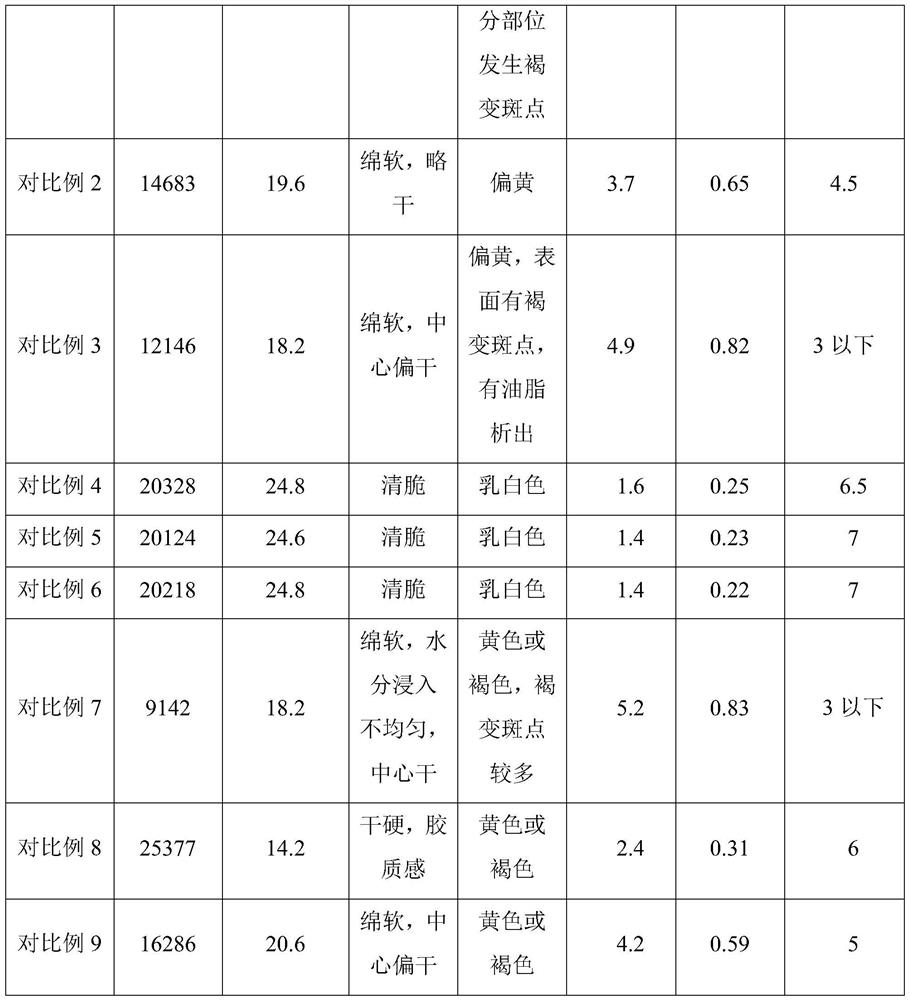

Examples

Embodiment 1

[0032] The preparation method of the rehydrated walnut kernel which can be preserved at normal temperature comprises the following steps:

[0033] Step 1. Wash the peeled walnut kernels and perform intermittent blanching, and then moisten to a moisture content of 5%. Intermittent blanching can remove the oil on the surface of the walnut kernels, passivate the enzyme activity of the walnut kernels, and reduce the storage of high-moisture walnut kernels The degree of product deterioration during the process is also conducive to the immersion of water when the walnut kernels are moistened. Due to the intermittent blanching, it can avoid the denaturation of the walnut kernel protein and the soft texture caused by long-term blanching.

[0034] Step 2, micro-expanding the treated walnut kernels in step 1 by vacuum microwave, so that the moisture content is reduced to 3%;

[0035] Step 3, after vacuum impregnating the processed walnut kernels in the step 2 in the embrittlement prote...

Embodiment 2

[0045] The preparation method of the rehydrated walnut kernel which can be preserved at normal temperature comprises the following steps:

[0046] Step 1. Wash the peeled walnut kernels and perform intermittent blanching, and then moisten to a moisture content of 7%. Intermittent blanching can remove the grease on the surface of the walnut kernels, passivate the enzyme activity of the walnut kernels, and reduce the storage of high-moisture walnut kernels The degree of product deterioration during the process is also conducive to the immersion of water when the walnut kernels are moistened. Due to the intermittent blanching, it can avoid the denaturation of the walnut kernel protein and the soft texture caused by long-term blanching.

[0047] Step 2, micro-expanding the walnut kernels treated in step 1 by vacuum microwave to reduce the moisture content to 4%;

[0048]Step 3, after vacuum impregnating the processed walnut kernels in the step 2 in the embrittlement protecting ag...

Embodiment 3

[0058] The preparation method of the rehydrated walnut kernel which can be preserved at normal temperature comprises the following steps:

[0059] Step 1: Clean the peeled walnut kernels, then blanch them intermittently, and then moisten until the water content is 10%.

[0060] Step 2, micro-expanding the treated walnut kernels in step 1 by vacuum microwave, so that the moisture content is reduced to 5%;

[0061] Step 3, after vacuum impregnating the processed walnut kernels in the step 2 in the embrittlement agent, cleaning;

[0062] Step 4, place the processed walnut kernels in the step 3 in the packaging bag and pour water into it, then pack it;

[0063] Step 5. Sterilize the packaged walnut kernels, cool them down to below 5°C after sterilization, let the walnut protein that has been heated for a long time recover its crisp texture, then return to room temperature, balance and replenish water, and then store at room temperature.

[0064] In the preparation method of rehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com