Preparation method of expanded graphite lubricating oil

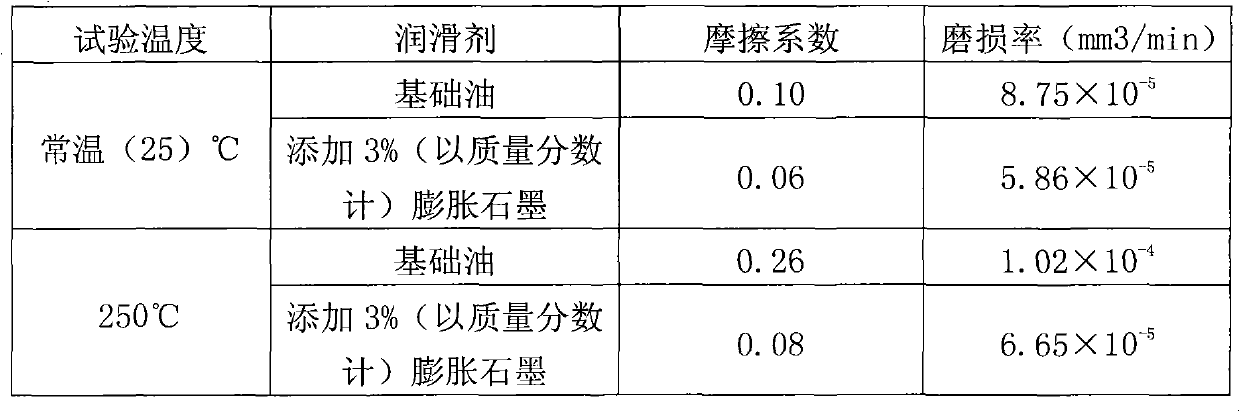

A technology of expanded graphite and expanded graphite powder, which is applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of easy temperature failure and narrow applicable temperature range, and achieve the degree of slowing down the deterioration and significantly reducing friction and anti-wear performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preparation of expanded graphite worms: Under laboratory conditions, chemical methods were used to prepare expanded graphite. Wherein, the raw material used is fine natural flake graphite with a particle size of 2000 meshes (purity: 99.9%, place of origin: Tonghua Far East Mining Co., Ltd.), the intercalation agent is concentrated sulfuric acid with a concentration of 98%, and the oxidizing agent is hydrogen peroxide with a concentration of 30%. Intercalation treatment at room temperature of about 25°C for 10 minutes, then washing the intercalated product with water to a pH value of 11, then drying at 1250°C for 0.5 hour, and performing high-temperature puffing treatment at 1200°C. An expanded graphite worm with an expansion factor of about 135 times was obtained.

[0014] Preparation of expanded graphite powder: place expanded graphite worms with an expansion factor of about 135 times in a propanol solvent, and stir them for about 15 minutes at a constant temperature a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com