Anti-cracking and mothproof treatment process for wood used for pet houses

A treatment process, pet nest technology, applied in wood treatment, wood treatment details, wood processing equipment, etc., can solve the problems of pet hazards, easy cracking, easy peeling of paint film, etc., to increase softness, reduce cracking, and prevent cracking and mothproof performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

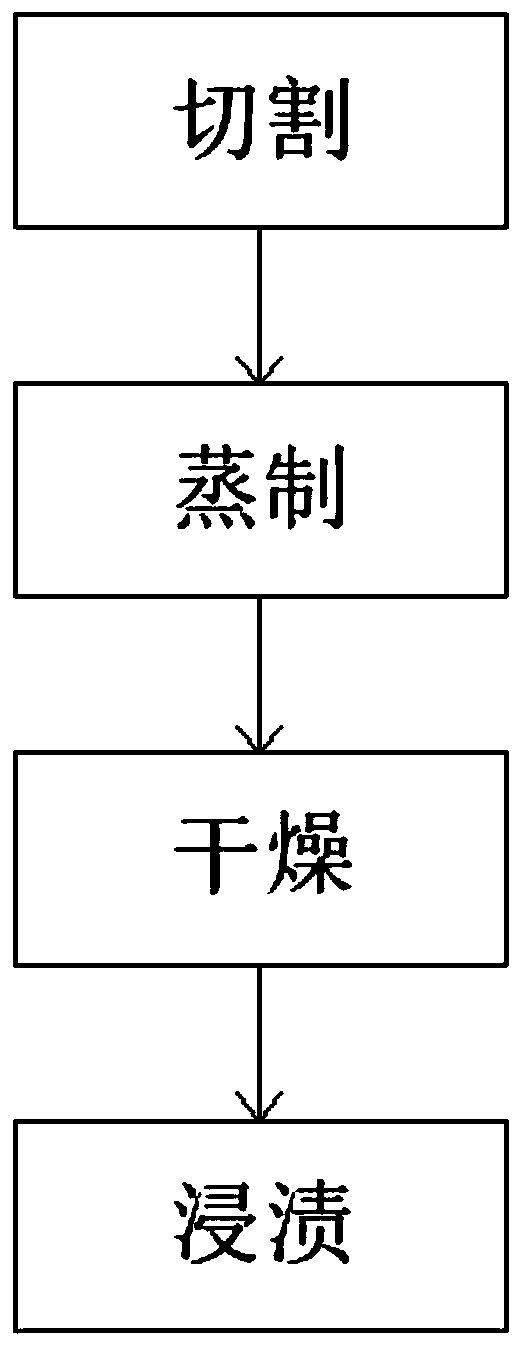

[0017] Embodiment 1, the present invention provides a technical solution: a wood anti-crack and anti-moth treatment process for pet nests, comprising the following steps:

[0018] (1) Cutting; cutting poplar wood into plates of required shape;

[0019] (2) Steaming: steam the plate in steam for 22 minutes, take it out, and naturally cool down to 36°C to obtain a steamed plate;

[0020] (3) Drying: place the plate in a freezer at minus 23°C for freeze-drying, and dry until the moisture content is 20%, to obtain a dry plate;

[0021] (4) Impregnation: Put the dry wood in a closed autoclave, add the treatment liquid, pressurize to 0.98MPa, keep it for 1 minute, and then use a pump to pump out a small amount of preservative solution to make the autoclave Generate a vacuum for 2 minutes, change the direction of the four-way valve, make the treatment liquid return to the autoclave by means of the liquid pump, and make the pressure in the autoclave reach 0.98MPa, last for 1 minute, ...

Embodiment 2

[0027] Embodiment 2, the present invention provides a technical solution: a wood anti-crack and anti-moth treatment process for pet nests, comprising the following steps:

[0028] (1) Cutting; cutting the birch into plates of the desired shape as required;

[0029] (2) Steaming: steam the plate in steam for 24 minutes, take it out, and cool it down to 37°C naturally to obtain a steamed plate;

[0030] (3) drying: place the plate in a freezer at minus 25°C for freeze-drying, and dry until the moisture content is 22%, to obtain a dry plate;

[0031] (4) Impregnation: Put the dry wood in a closed autoclave, add the treatment liquid, fill up the tank, pressurize to 1MPa, keep it for 1 minute, and then pump out a small amount of preservative solution to make the autoclave produce Vacuum for 2 minutes, change the direction of the four-way valve, make the treatment liquid return to the autoclave by means of the liquid pump, and make the pressure in the autoclave reach 1MPa, continue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com