Double-curing one-component bamboo wood waterproof coating and application thereof

A waterproof coating and dual-curing technology, which is applied in the field of building decoration materials, can solve the problems of unsatisfactory waterproof and anti-cracking effects, affecting the use effect and service life, occupying space, and low production efficiency, achieving excellent adhesion and broad market Application prospects, the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

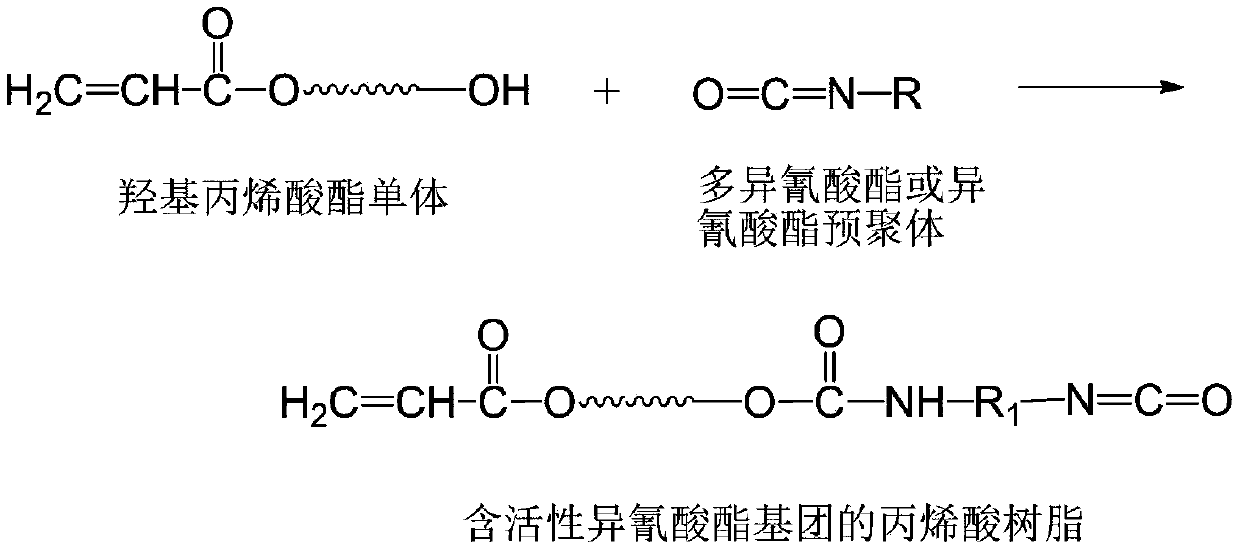

[0024] A dual-cure one-component waterproof coating for bamboo wood, comprising the following components in parts by weight: 70 parts of acrylic resin containing active isocyanate groups, 12 parts of 1,6-hexanediol diacrylate, dipropylene glycol diacrylate 12 parts, 2,4,6-(trimethylbenzoyl)diphenylphosphine oxide 2 parts, 1-hydroxycyclohexyl phenyl ketone 2 parts, polyisocyanate 1 part. Wherein, the acrylic resin containing active isocyanate groups is obtained by reacting hydroxyethyl acrylate and polyisocyanate, and the content of isocyanate groups in the acrylic resin containing active isocyanate groups is controlled to be 8%.

[0025] The waterproof coating in this embodiment is coated on the surface of bamboo, and the waterproof coating is obtained after infrared leveling and radiation curing. Control the coating amount to 20g / m 2 , the infrared leveling temperature is 60°C, the leveling line length is 7m; the radiation curing method is a combination of UV curing and LED ...

Embodiment 2

[0028] A dual-cure one-component waterproof coating for bamboo wood, comprising the following components by weight: 31.5 parts of acrylic resin containing active isocyanate groups, 20 parts of 1,6-hexanediol diacrylate, dipropylene glycol diacrylate 20 parts, 20 parts of trimethylolpropane triacrylate, 3 parts of 2,4,6-(trimethylbenzoyl) diphenylphosphine oxide, 4 parts of 1-hydroxycyclohexyl phenyl ketone, phenyl 1 part of bis(2,4,6-trimethylbenzoyl)phosphine oxide, 0.5 part of polyisocyanate. Wherein, the acrylic resin containing active isocyanate groups is obtained by reacting hydroxypropyl methacrylate and isocyanate prepolymer, and the content of isocyanate groups in the acrylic resin containing active isocyanate groups is controlled to be 10%.

[0029] The waterproof coating in this embodiment is coated on the surface of bamboo, and the waterproof coating is obtained after infrared leveling and radiation curing. Control the coating amount to 50g / m 2 , the infrared leve...

Embodiment 3

[0032] A dual-cure one-component waterproof coating for bamboo wood, comprising the following components in parts by weight: 98 parts of acrylic resin containing active isocyanate groups, 2,4,6-(trimethylbenzoyl) diphenylphosphine oxide 0.5 parts, polyisocyanate 1.5 parts. Wherein, the acrylic resin containing active isocyanate groups is obtained by reacting polyethylene glycol monoacrylate and polyisocyanate, and the content of isocyanate groups in the acrylic resin containing active isocyanate groups is controlled to be 5%.

[0033] The waterproof coating in this embodiment is coated on the wood surface, and the waterproof coating is obtained after infrared leveling and radiation curing. Control the coating amount to 10g / m 2 , the infrared leveling temperature is 40°C, the leveling line length is 10 meters; the radiation curing method is a combination of EB curing and LED curing.

[0034] After the wood surface is coated with waterproof paint, it has excellent waterproof a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com