Manufacture method for insulated gate bipolar transistor (IGBT) device

A manufacturing method and device technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as fragmentation incidents, increased warpage of silicon wafers, and inability to tape out silicon wafers, so as to solve transmission problems and improve The effect of warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In one embodiment of the present invention, the manufacturing method of the IGBT device includes the following steps:

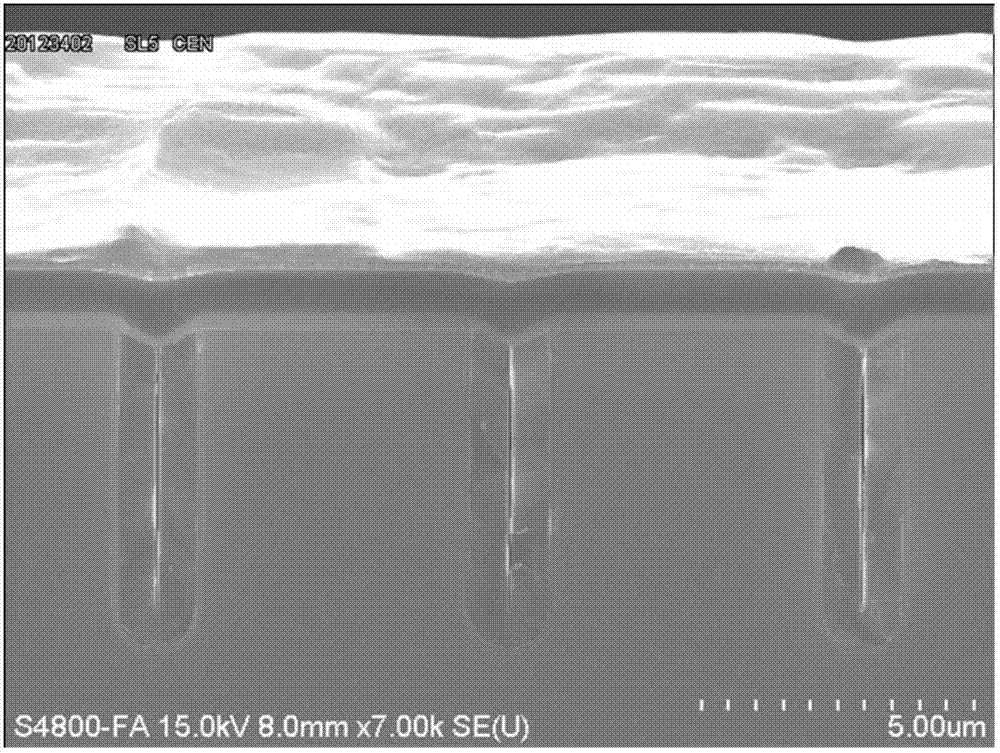

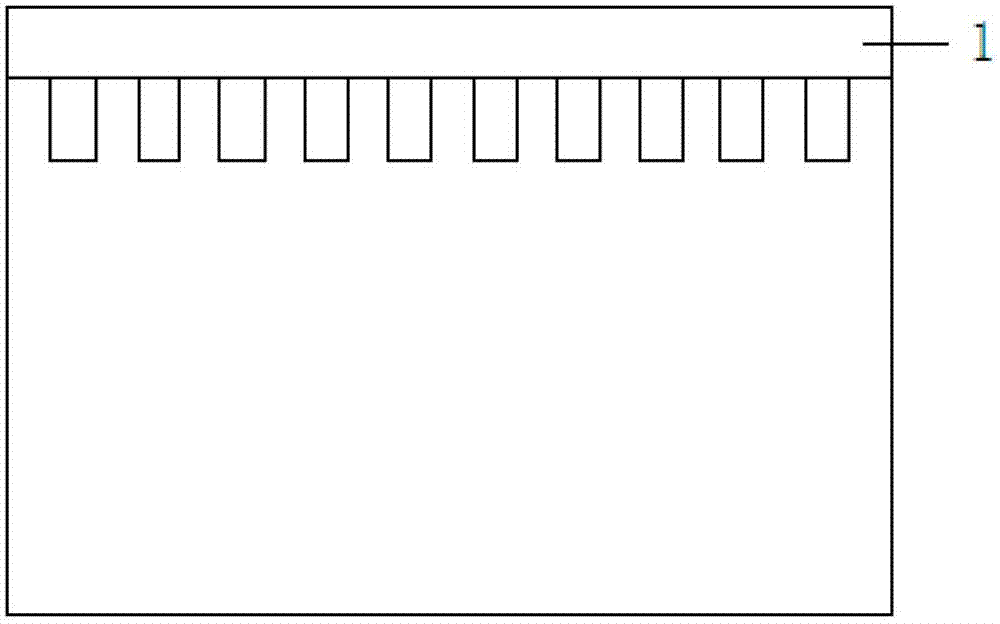

[0018] first step, combine figure 2 As shown, trench etching is performed sequentially on the silicon wafer for making IGBT separation devices, a gate oxide layer is formed in the trench, and then the trench is filled with polysilicon (ie, gate polysilicon). A pre-metal dielectric layer 1 is deposited on the upper end surface of the silicon wafer (that is, the front side of the silicon wafer) of the part structure of the IGBT separation device that has been formed.

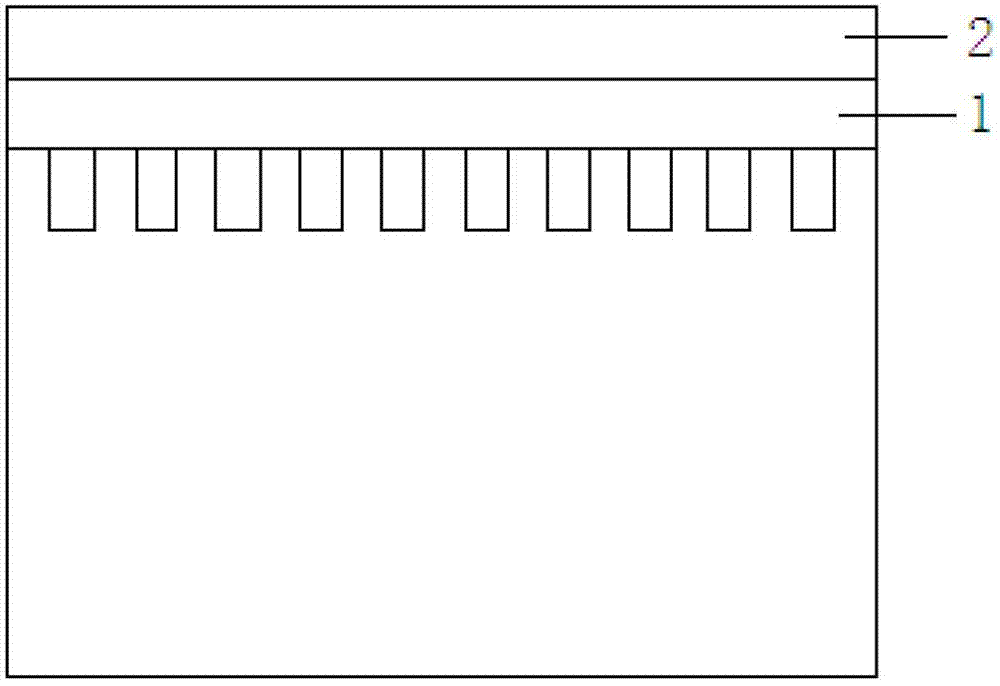

[0019] Step two, combine image 3 As shown, a protective film 2 is deposited on the upper end of the pre-metal dielectric layer 1, and the protective film 2 can effectively prevent possible scratches on the front surface of the device during subsequent back process steps. The protective film 2 is generally an atmospheric pressure CVD (chemical vapor deposition) film, or a film of other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com