Back coating material for tipping paper for cigarettes, tipping paper for cigarettes, and preparation method of tipping paper

A cigarette tipping paper and back-coating technology, applied in paper coating, coating, papermaking, etc., can solve the problem of low surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a preparation method of the above-mentioned back coating material for tipping paper for cigarettes, comprising the following steps:

[0035] S100, adding the resin into the diluent and stirring to completely dissolve the resin to obtain a resin solution;

[0036] S200, adding other ingredients into the resin solution and mixing them uniformly to obtain the back coating material.

[0037] The present invention further provides a tipping paper for cigarettes, comprising a base paper layer, a printing layer formed on one surface of the base paper layer and a backcoat layer formed on the other surface of the base paper layer, the backcoat layer formed by the above-mentioned The backcoat material is formed after drying. The substrate layer can be base paper for tipping paper, high-gloss paper, impervious paper or aluminized transfer paper. The coating amount of the back coating material is 0.5g / m 2 up to 1.2g / m 2 .

[0038] The prepar...

Embodiment 1

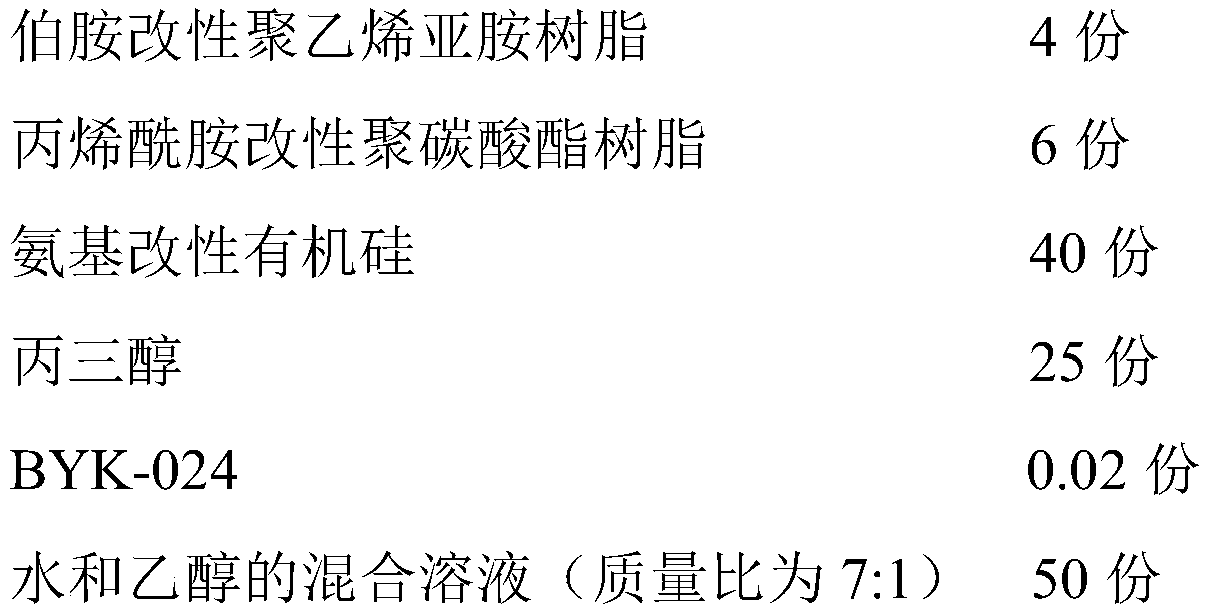

[0046] The back coating material of this embodiment adopts the following components and the raw materials of content to prepare:

[0047]

[0048] Above-mentioned back coating material is prepared according to the following steps:

[0049] Add primary amine-modified polyethyleneimine resin and acrylamide-modified polycarbonate resin into a mixed solution of water and ethanol (the mass ratio of water and ethanol is 7:1) for stirring, and make it completely dissolved, and then add amino Mix the modified silicone, glycerin and BYK-024 evenly to obtain the finished product.

Embodiment 2

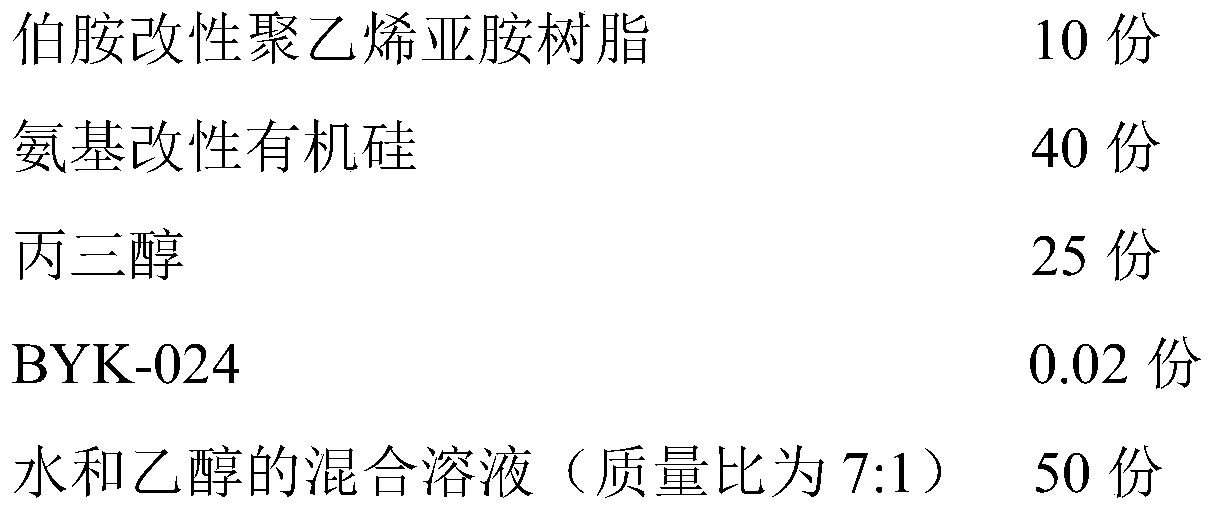

[0051] The back coating material of this embodiment adopts the following components and the raw materials of content to prepare:

[0052]

[0053] Above-mentioned back coating material is prepared according to the following steps:

[0054] Add the primary amine-modified polyethyleneimine into the mixed solution of water and ethanol (the mass ratio of water and ethanol is 7:1) for stirring, and make it completely dissolved, then add amino-modified silicone, glycerol and BYK- 024 Mix evenly to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com