Method for manufacturing QFN (quad flat no-lead) package device

A manufacturing method and a technology for packaging devices, which are applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of not being able to meet high density, limit the number of I/Os, increase packaging costs, etc., and achieve high I/O O density, high manufacturing precision, and the effect of eliminating air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing:

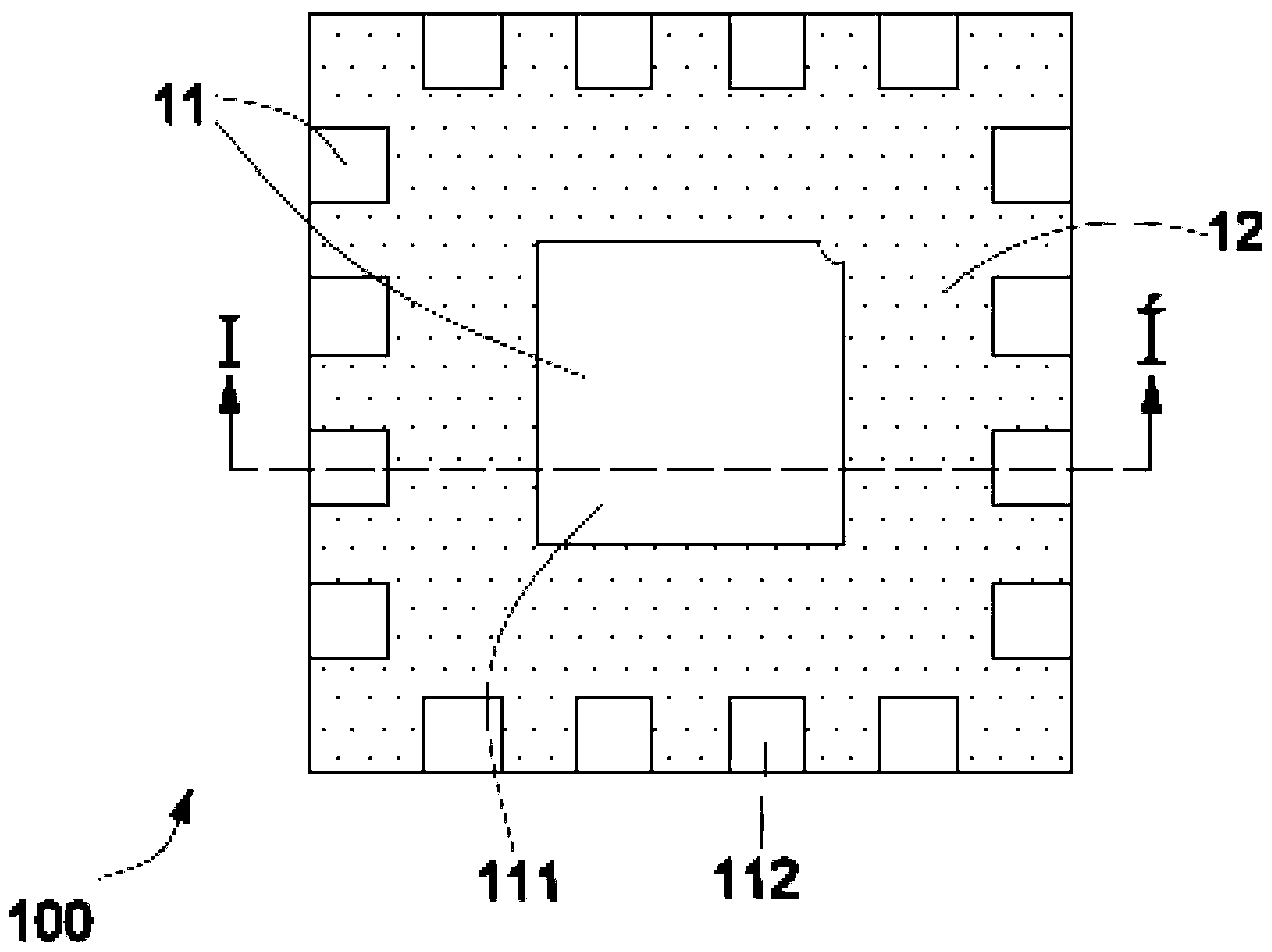

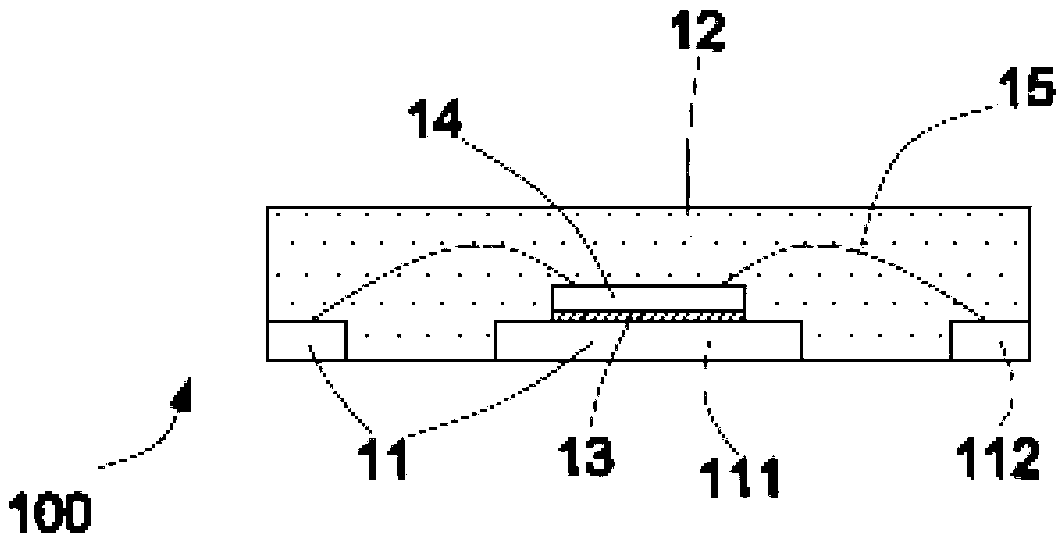

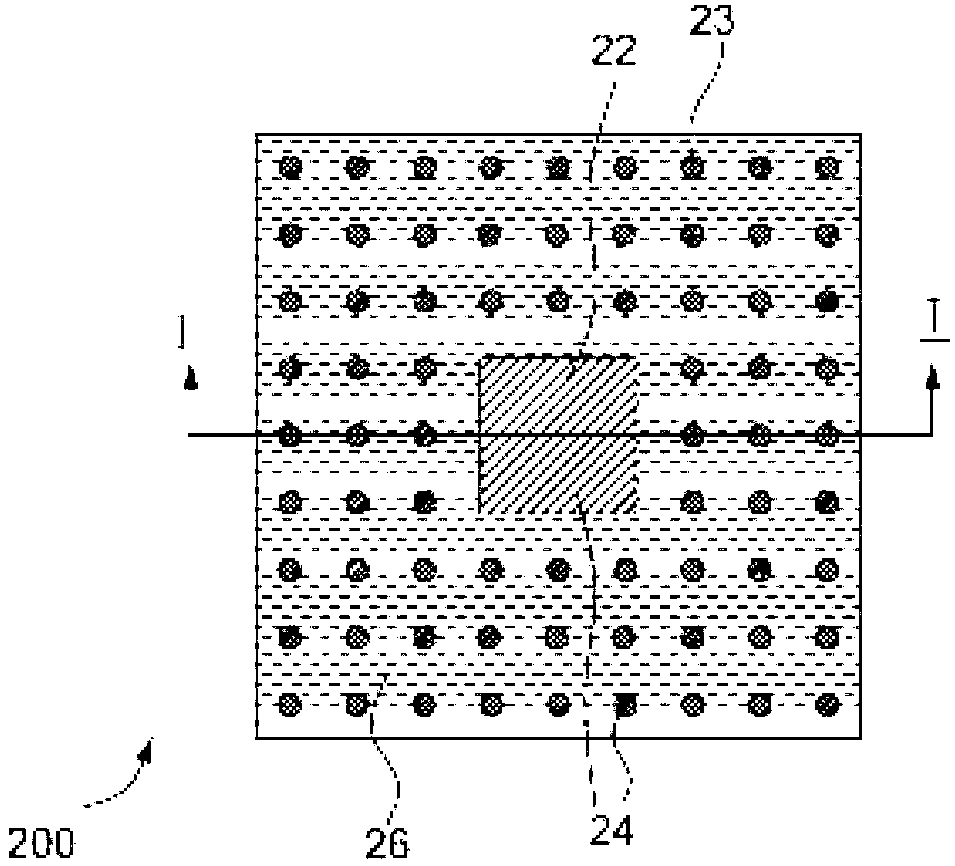

[0043] Figure 2A A schematic diagram of the back side of a multi-circle pin arrangement QFN packaged device drawn according to an embodiment of the present invention where the cross section of the pins is circular and the pins are arranged in parallel on each side of the chip carrier. Figure 2B A schematic diagram of the back side of a QFN packaged device in which the cross-section of the pins is rectangular and the pins on each side of the chip carrier are arranged in parallel according to the embodiment of the present invention.

[0044] Refer to the above Figure 2A-2B It can be seen that, in this embodiment, the QFN packaging device 200 with multi-circle pin arrangement has a chip carrier 22 and pins 23 arranged in multiple turns around the chip carrier 22, and the arrangement of the pins 23 on each side of the chip carrier 22 For parallel arrangement, a first metal ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com