Automatic charging tray feeding system

A technology of automatic feeding and trays, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of conveyor belt motor damage, difficulty in ensuring directionality, long assembly time, etc., to improve accuracy and reduce The effect of manual labor intensity and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

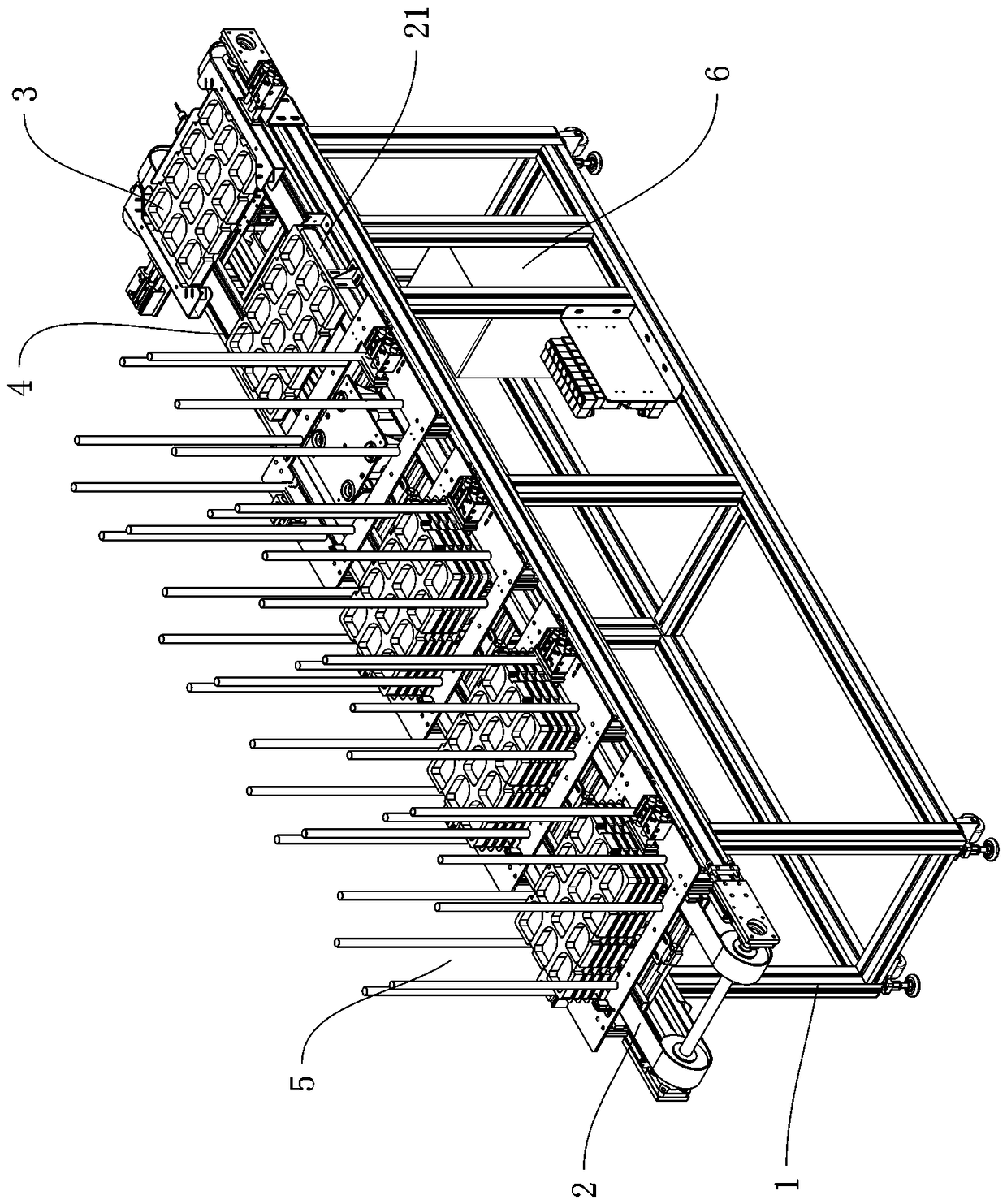

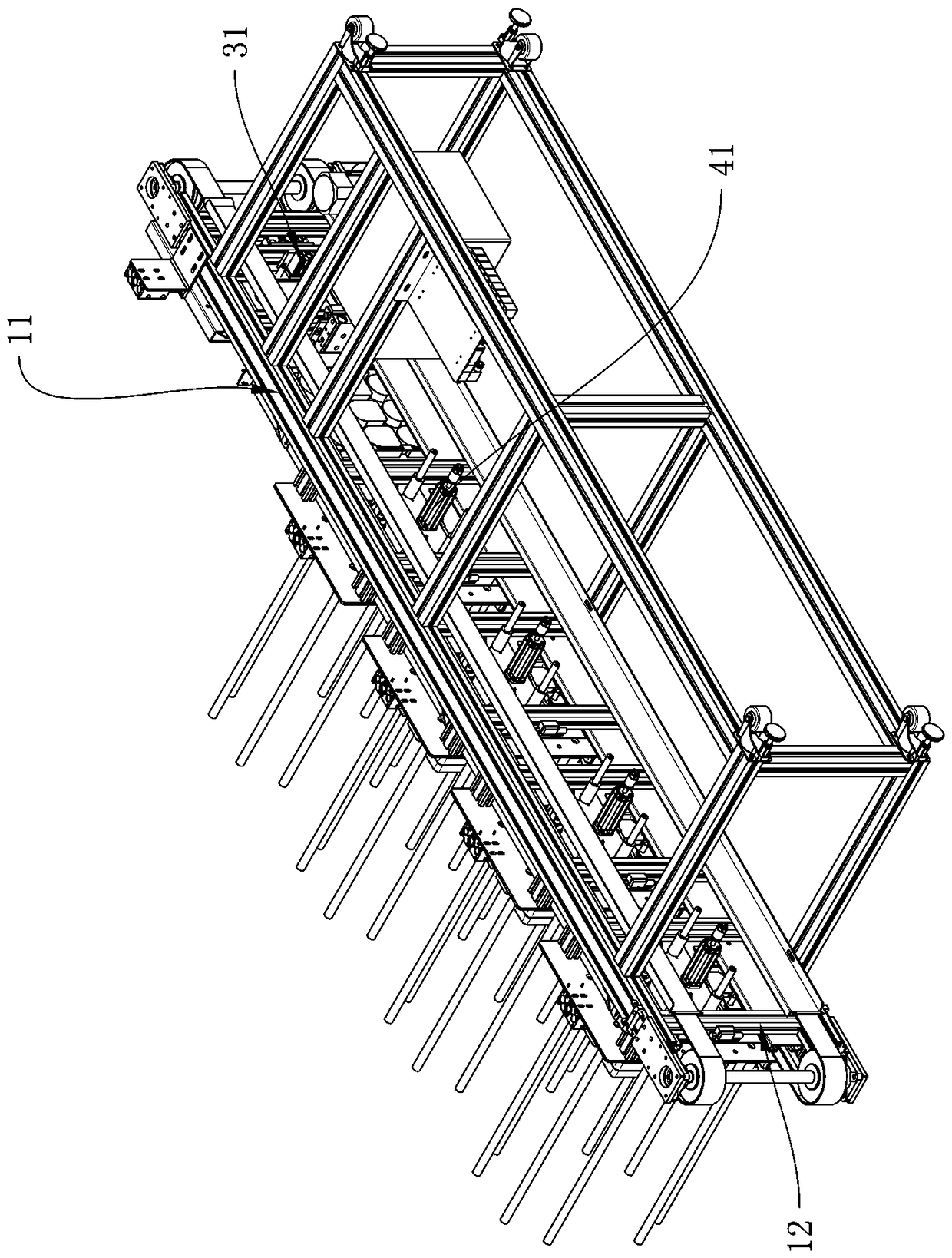

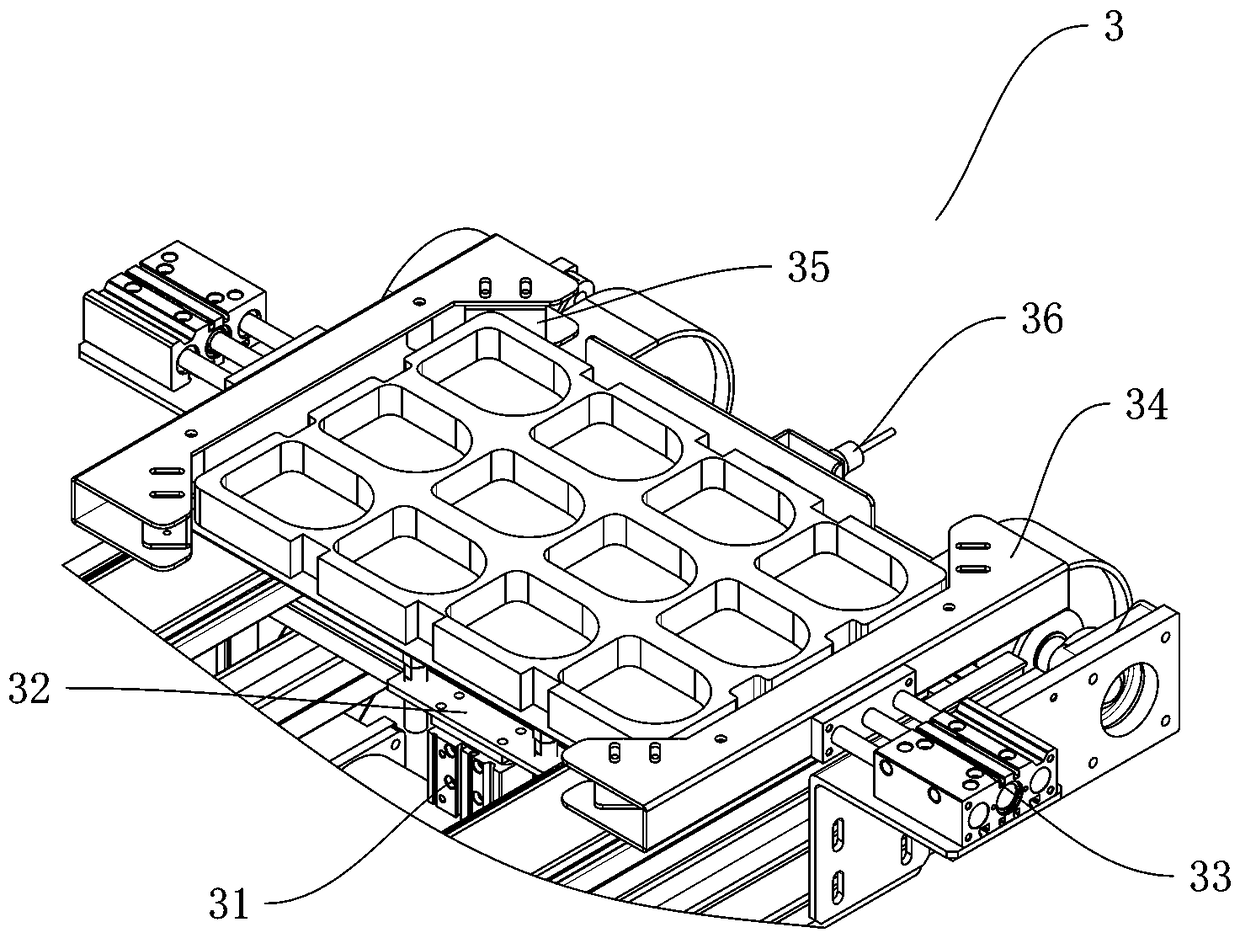

[0025] Figure 1~5 It is a preferred solution of the present invention, including a frame 1, a conveyor belt 2, an assembly positioning mechanism 3, a waiting position 4, a material bin 5 and an electric control box 6.

[0026] The upper part of the frame 1 is a conveying platform composed of two beams 11 and several longitudinal beams 12, the lower part is a support, and the conveyor belt 2 is two plastic chains, which are respectively installed inside the two beams 11 and bypass the longitudinal beams to form a rotary conveyor belt , The two chains on the left and right are spaced apart to form a conveying surface.

[0027] The silo 5, the waiting position 4, and the assembly positioning mechanism 3 are sequentially arranged along the conveying direction from back to fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com