Flexible OLED substrate and fabrication method thereof

A flexible, substrate-based technology, applied in the field of flexible OLED substrates and its preparation, can solve the problems of inability to meet OLED's requirements for the flatness of conductive film, unfavorable charge injection of OLED devices, short-circuit breakdown of devices, etc., to improve the uniformity of electric field performance, improve flatness, and reduce internal resistance and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

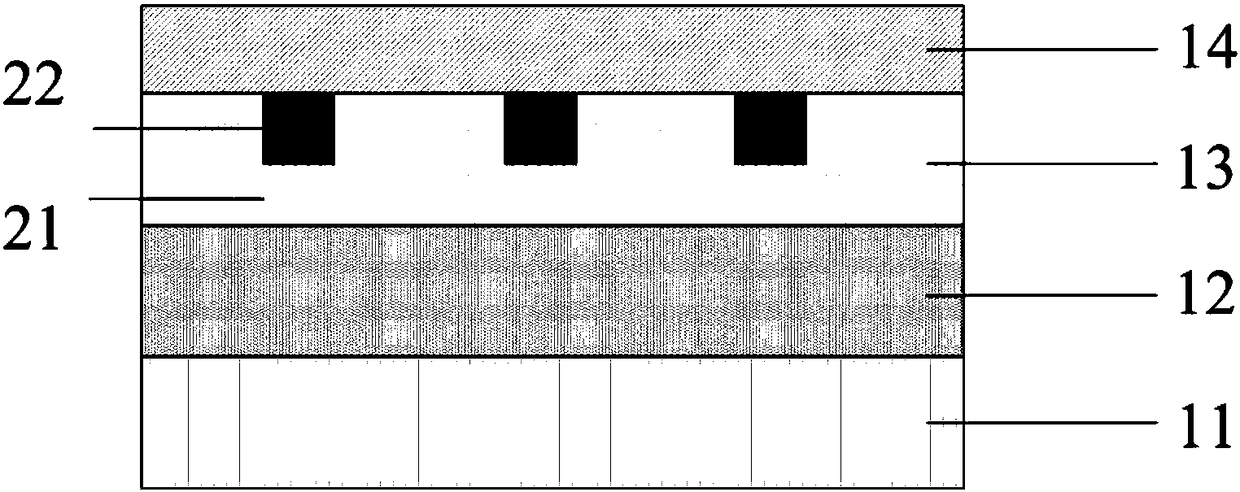

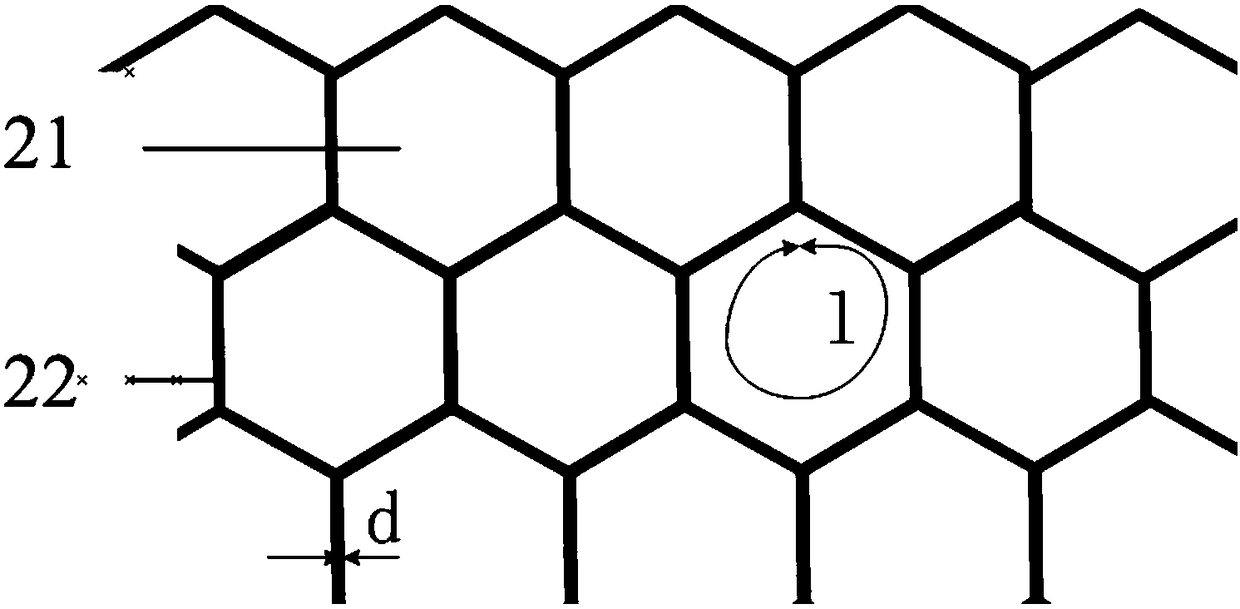

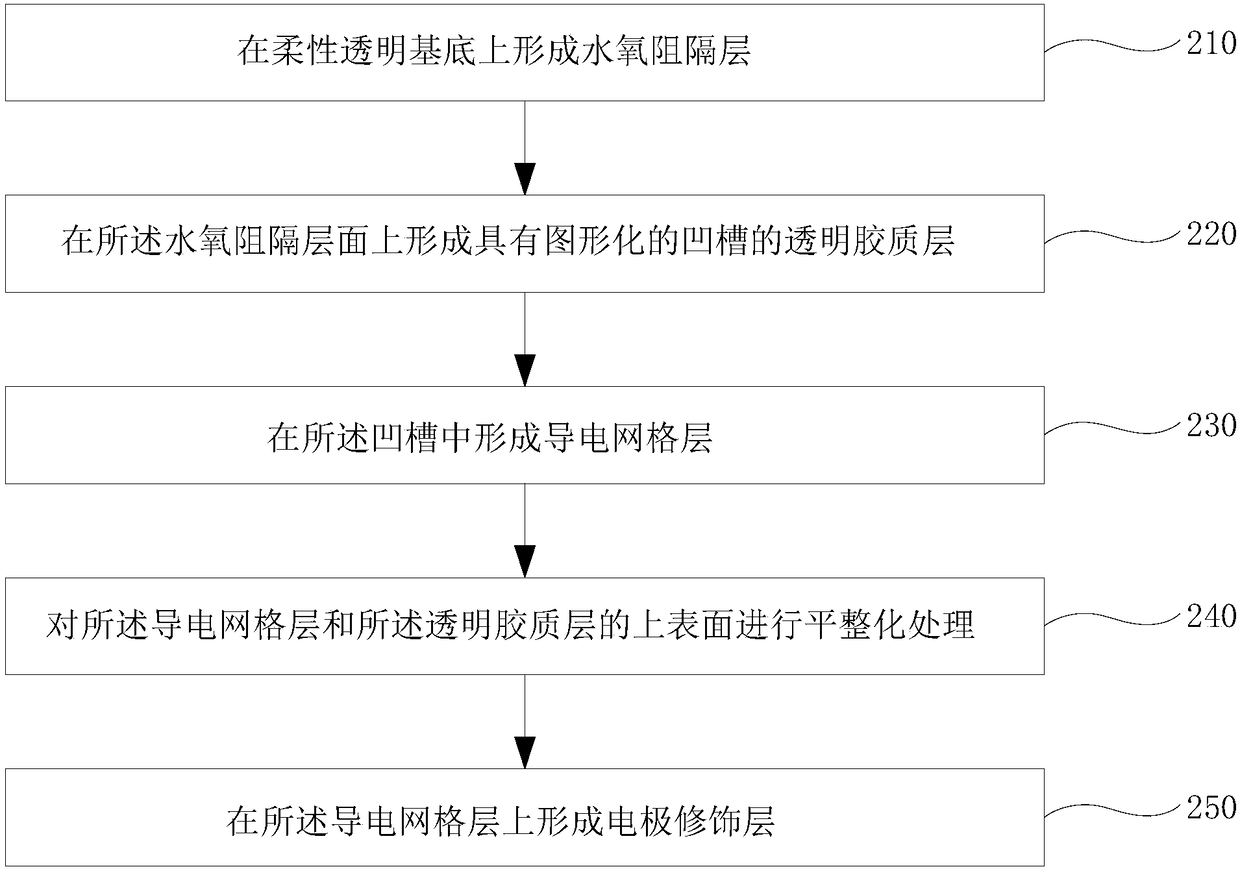

[0053] The embodiment of the invention also provides a preparation method of the flexible OLED substrate. refer to image 3 , the step of preparing a flexible OLED substrate specifically includes:

[0054] In step 210 , a water-oxygen barrier layer 12 is formed on the flexible transparent substrate 11 . Specifically, an organic / inorganic silicon hybrid high water oxygen barrier layer 12 is deposited on a flexible substrate by ICP-PECVD. Specifically, it is discharged by a high-density plasma source ICP source in a vertical direction, the sample is placed on the sample stage, the vacuum degree of the discharge deposition condition can be 0.1Pa-10Pa, and the discharge power of the ICP source can be 100W-1200W. Siloxane as precursor source, with O 2 , N 2 O, NH 3 Ar gas is used as the oxidizing gas source, and Ar gas is used as the auxiliary ionized gas source. By periodically adjusting the power of the ICP source and the different ratios of the precursor source and the oxid...

Embodiment 2

[0079] According to another embodiment of the present invention, a high temperature resistant flexible OLED substrate is also provided.

[0080] Specifically, the PEN substrate in Example 1 is replaced by a polyimide (PI) substrate resistant to high temperatures of 300°C, and at the same time, the transparent colloid layer 21 in the transparent conductive layer 13 is replaced by a polyimide (PI) substrate with a silicon element content exceeding 30%. High temperature UV glue, in addition, the etching time for the transparent glue layer 21 needs to be extended to 30s in the etching and thinning process, and other structures and preparation methods are consistent with Example 1, and a high temperature resistant flexible OLED substrate can be obtained.

Embodiment 3

[0082] According to another embodiment of the present invention, a flexible OLED substrate with thermal shock resistance is also provided.

[0083] Specifically, the PEN substrate in Example 1 is replaced with a tough thermoplastic resin polycarbonate (PC) substrate, and the transparent gel layer 21 in the transparent conductive layer 13 is replaced with a flexible substrate that can withstand 150% tensile deformation. In addition, the etching time for the transparent colloidal layer 21 in the etching thinning process is shortened to 15s. Other structures and preparation methods are consistent with those in Example 1, and a flexible OLED substrate capable of certain thermal shock resistance can be obtained.

[0084] It should be emphasized that the water and oxygen barrier layer 12 has an important impact on the lifetime of the OLED device. In the following, the influence of the water and oxygen barrier layer 12 on the lifetime of the OLED device will be compared and analyzed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com